Vehicle battery replacing method and control system

A technology of control system and electrical method, which is applied in vehicle energy storage, vehicle components, charging stations, etc., and can solve problems such as poor experience in battery replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

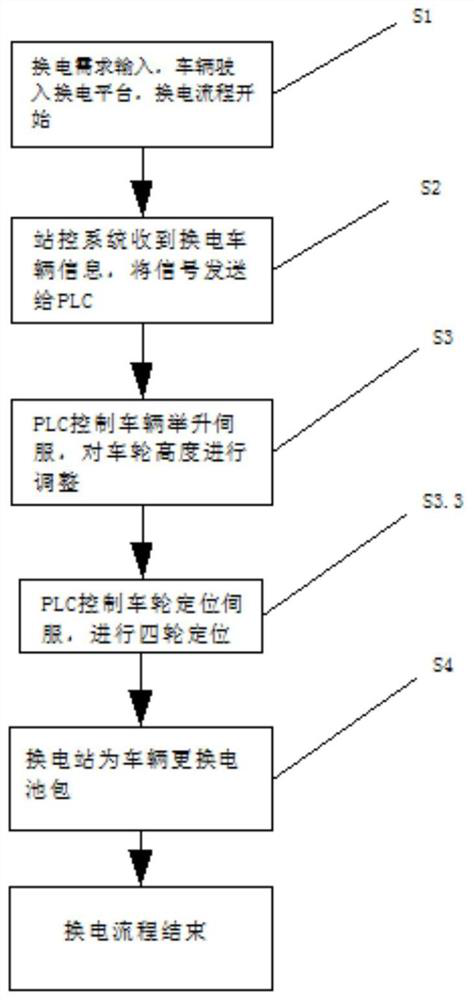

[0042] like figure 1 As shown, it is a method for a specific vehicle battery replacement in the embodiment of the present invention, and the method includes:

[0043] S1: The demand for battery swap is input, the vehicle drives into the battery swap platform, and the battery swap process begins.

[0044] It should be noted that the battery replacement method in this embodiment may be, but not limited to, battery replacement for electric vehicles, where the electric vehicles include pure electric vehicles, hybrid electric vehicles, and the like.

[0045] S2: The station control system receives the information of the battery replacement vehicle and sends the signal to the PLC.

[0046] S3: PLC controls the vehicle lifting servo to adjust the height of the wheels respectively.

[0047] In this embodiment, motors, electric cylinders, cylinders, etc. can be used as driving forces, and vertical slide rails, cam mechanisms, rigid chains, screw rods, gears, etc. can be used as trans...

Embodiment 2

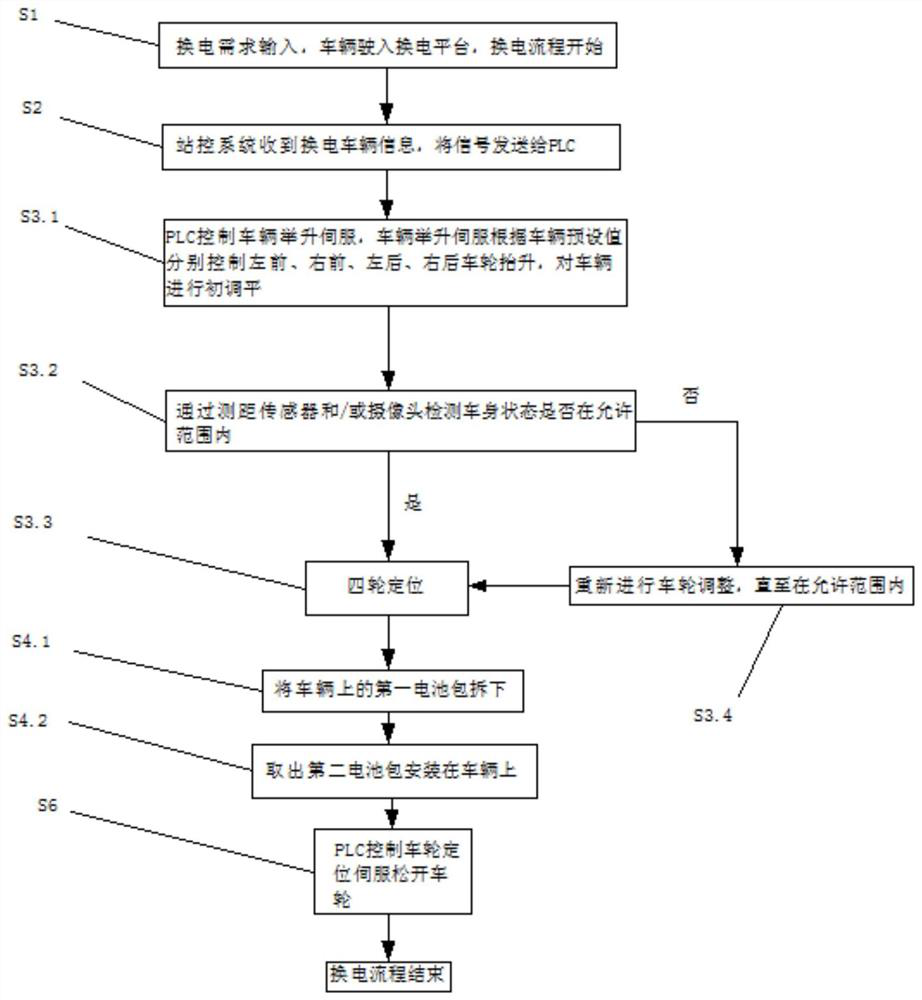

[0055] like Figures 1 to 2 As shown, it is a method for a specific vehicle battery replacement in the embodiment of the present invention, and the method includes:

[0056] S1: The demand for battery swap is input, the vehicle drives into the battery swap platform, and the battery swap process begins.

[0057] S2: The station control system receives the information of the battery replacement vehicle and sends the signal to the PLC.

[0058] S2.1: PLC controls the front wheel translation servo to translate the vehicle in place.

[0059] In this embodiment, motors, electric cylinders, cylinders, etc. can be used as driving forces, and vertical slide rails, cam mechanisms, rigid chains, screw rods, gears, etc. can be used as transmission devices.

[0060] In this embodiment, the PLC transmits the command to the front wheel translation servo, and the front wheel translation servo drives the motor to translate the front wheels of the vehicle in place to straighten the vehicle body...

Embodiment 3

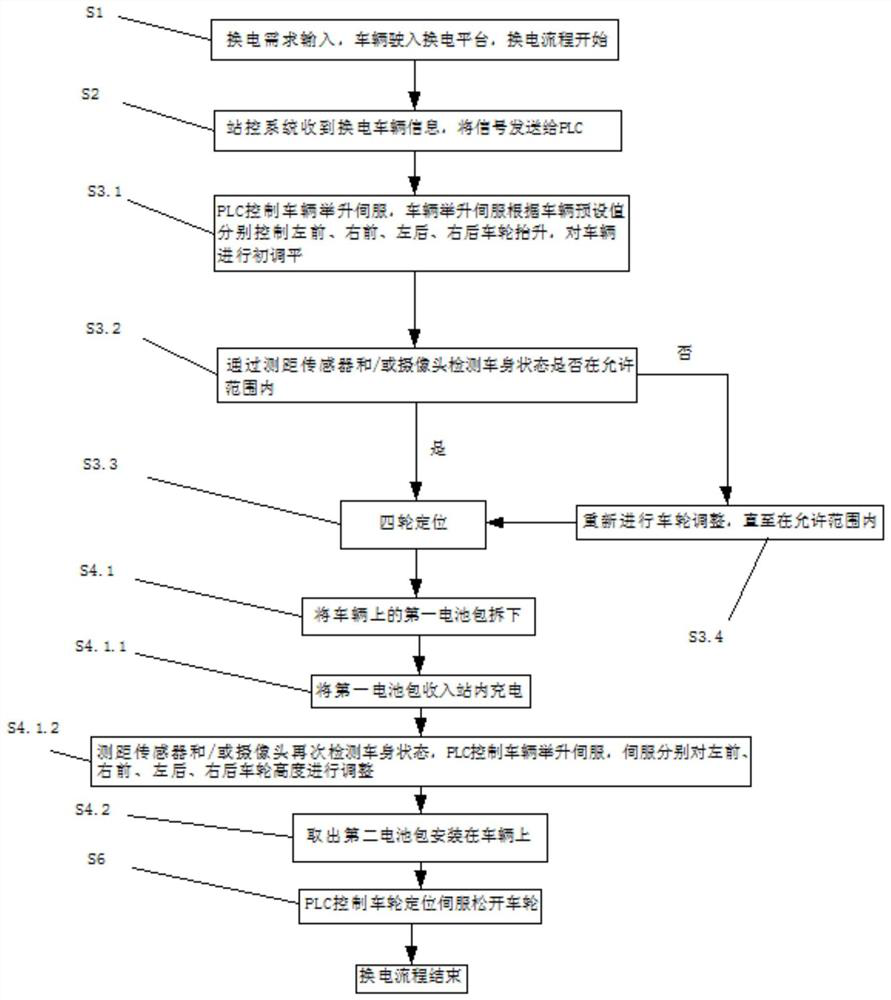

[0074] like Figures 1 to 3 As shown, it is a method for a specific vehicle battery replacement in the embodiment of the present invention, and the method includes:

[0075] S1: The demand for battery swap is input, the vehicle drives into the battery swap platform, and the battery swap process begins.

[0076] S2: The station control system receives the information of the battery replacement vehicle and sends the signal to the PLC.

[0077] S2.1: PLC controls the front wheel translation servo to translate the vehicle in place.

[0078] S3.1: PLC controls the vehicle lifting servo, and the vehicle lifting servo controls the lifting of the left front, right front, left rear, and right rear wheels respectively according to the preset value of the vehicle, and performs initial leveling of the vehicle.

[0079] After the initial leveling of the vehicle, S3.2: Check again whether the state of the vehicle body is within the allowable range through the ranging sensor and / or camera....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com