Method for grabbing specified part of shaft workpiece for feeding

A technology for shaft workpieces and parts, which is applied in the field of automatic feeding, can solve problems such as inaccurate axis angles, and achieve the effects of less positional constraints, less grabbing and touching, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

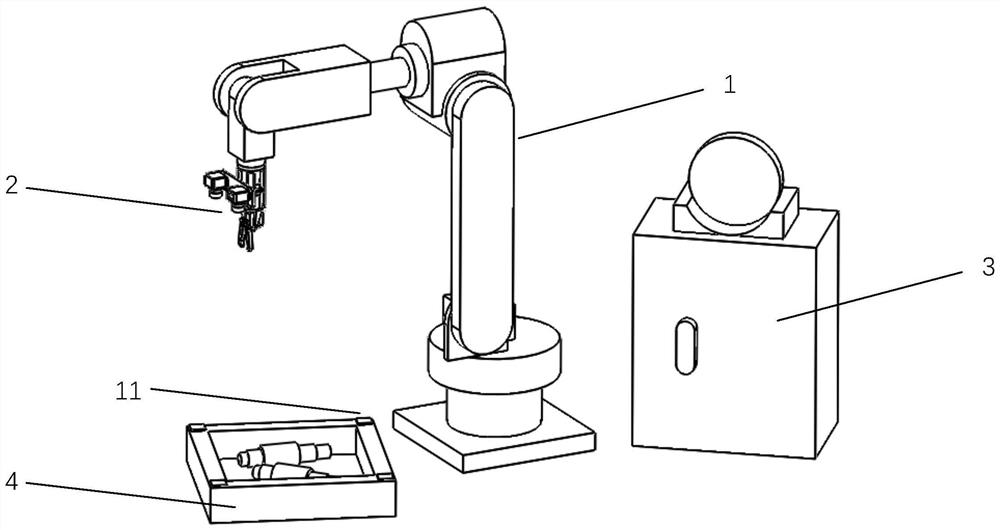

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] As shown in the accompanying drawings, a method for grabbing a specified part of a shaft workpiece according to the present invention for loading includes the following steps:

[0033] Step 1. Connect the device and paste a rectangular sticker 11 of a specific color on the four corners of the top frame of the open material box 4;

[0034] The open material box 4 is a rectangular body without a top, and several non-overlapping shaft parts are laid flat in the material box. The area where the shaft workpiece is located is the rectangular area that accommodates shaft parts in the material box 4 , that is, the rectangular area after the frame is removed from the open material box 4 .

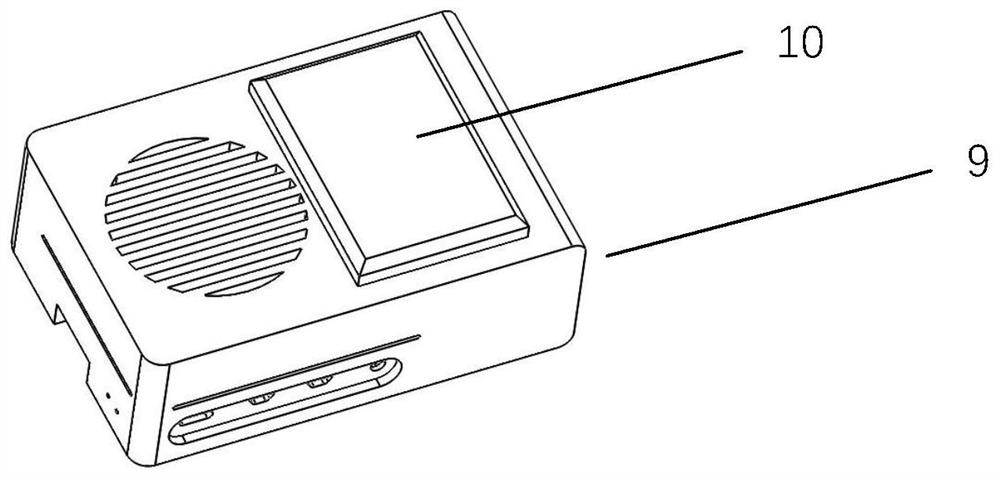

[0035] The process of connecting the equipment is as follows: install the end effector 2 on the end of the mechanical arm 1, and connect the control line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com