Four-axis manipulator with extruded profile

A technology of four-axis manipulator and extrusion profile, which is applied in the field of manipulators, can solve the problems of insufficient light weight, high material cost, long processing time, etc., achieve high protection level, reduce material consumption, and reduce self-weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

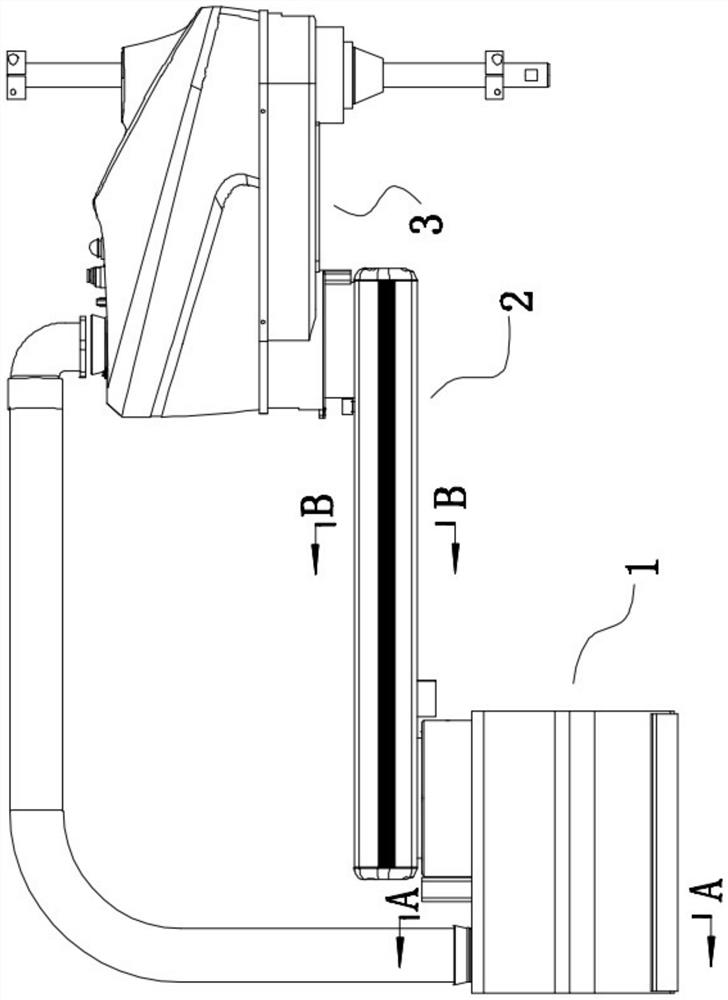

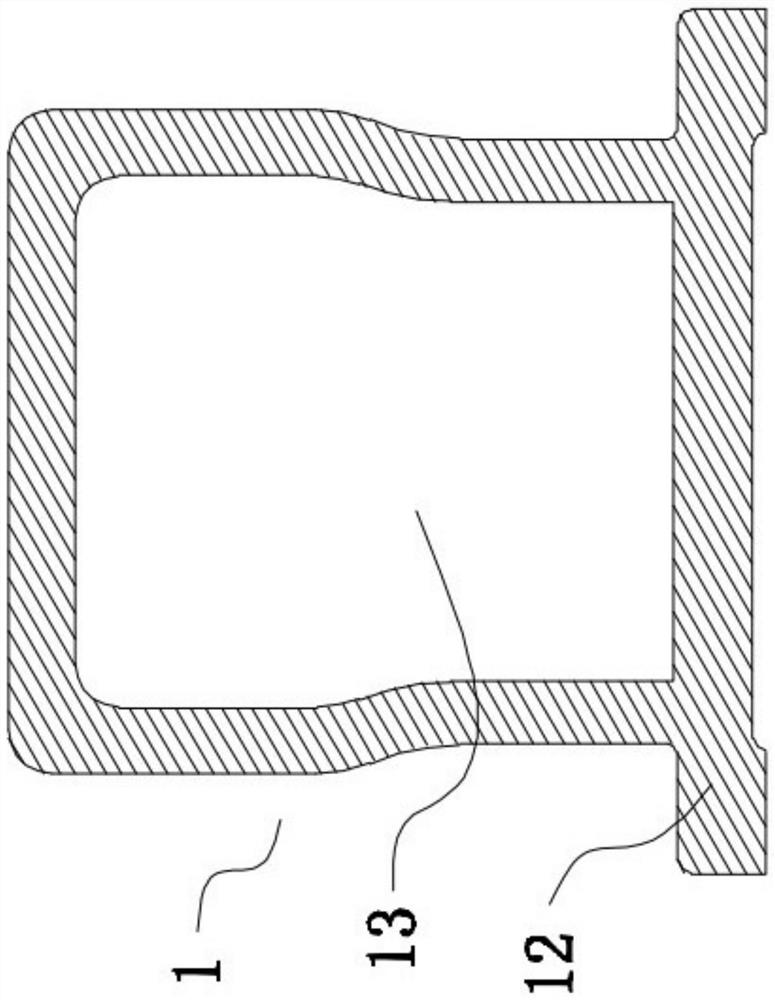

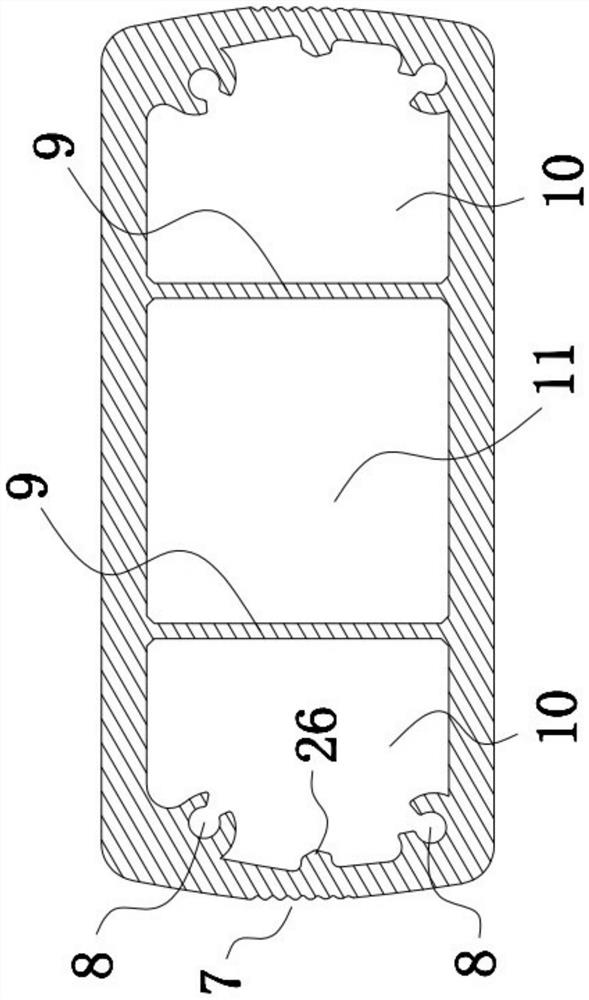

[0040] In order to achieve the purpose of the present invention, a four-axis manipulator with extruded profiles includes: a machine base 1, which is an extruded profile with the same cross-sectional profile; It is an extruded profile with the same cross-sectional profile; the wrist part 3, the end of the arm part 2 away from the machine base 1 is connected to the wrist part 3, and the wrist part 3 is a casting, and the two ends of the wrist part 3 along its own length direction have arcs Plate 16, the wrist part 3 has an upward opening, the edge profile of the opening is a waist-shaped hole, the opening is buckled with a cover 4, the inner wall of the wrist part 3 has an inner convex part 17 that increases its own thickness, and the inner convex part 17 is provided with a There are blind holes 18;

[0041] The beneficial effect of adopting the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com