Dust removing and blowing device for binding equipment

A technology of blowing device and equipment, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problem of affecting the surface quality of vehicle parts, shortening the debugging cycle, and forming pits on the outer surface of the outer plate. and other problems, to avoid surface quality defects of parts, reduce the risk of damage to tire molds, and reduce manual participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

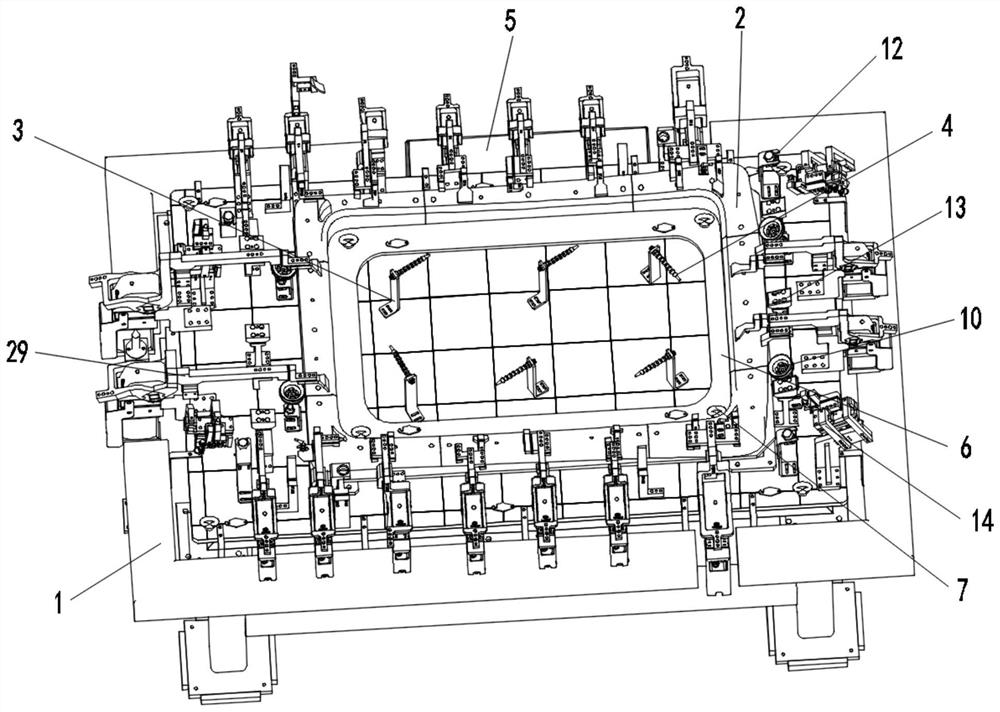

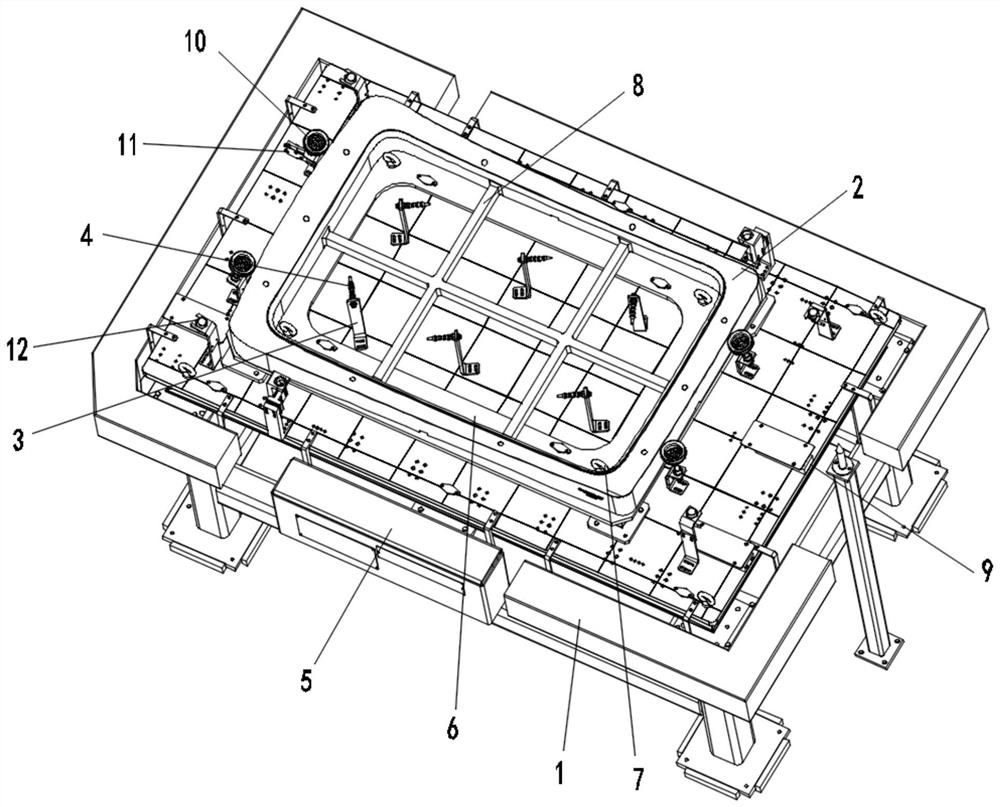

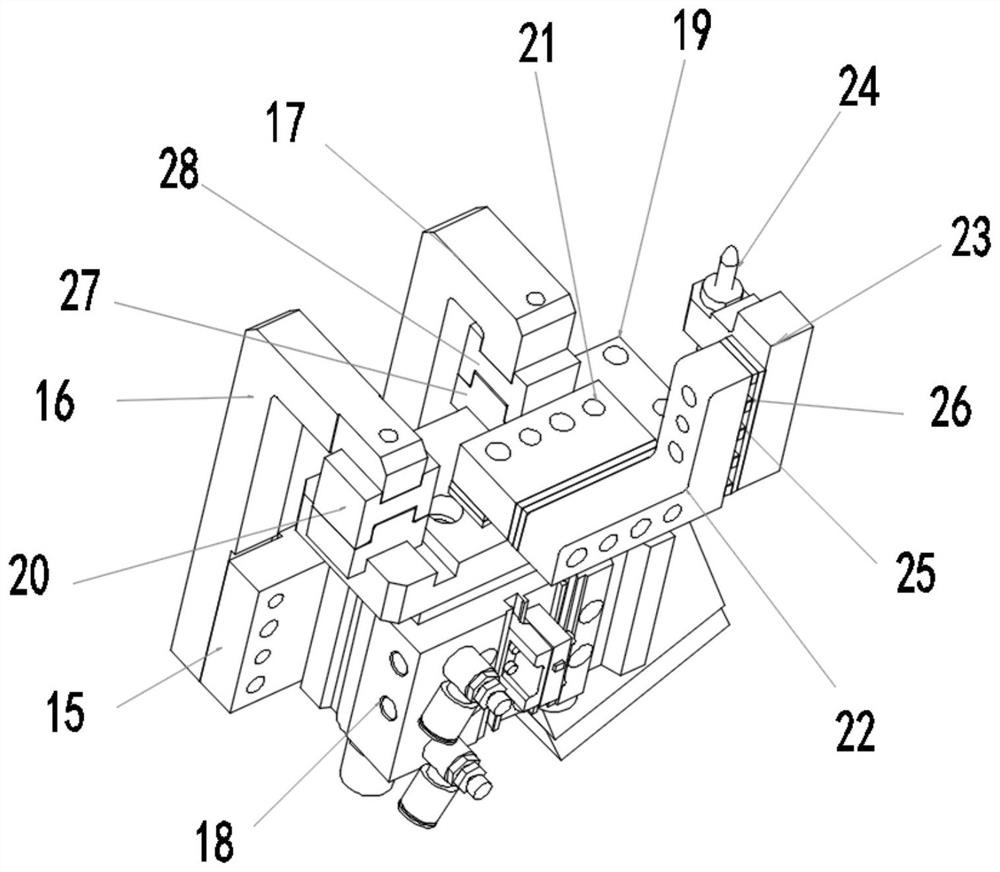

[0023] A dust removal and blowing device for hemming equipment, comprising a base 1 and a tire mold 2; the tire mold 2 is installed on the base 1; the tire mold 2 is a hollow structure; the inside of the tire mold 2 is provided with a plurality of brackets 3 connected to the base 1; A nozzle 4 is installed on the bracket 3; a valve island 5 is installed on one side of the base 1, and the valve island 5 is connected to the nozzle 4 through a pipe.

[0024] There is a gap between the tire mold 2 and the base 1; the pipe used for the communication between the valve island 5 and the nozzle 4 passes through the gap.

[0025] The inner wall of tire mold 2 is provided with a circle of rim 6, and the upper end of rim 6 is provided with suspension ring 7; The mesh structure, the nozzles 4 are located in the meshes of the mesh structure.

[0026] A gas distribution block 9 is provided on the pipeline between the valve island 5 and the nozzle 4 and the gas distribution block 9 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com