Dehydrating agent for aluminum hydroxide and preparation method thereof

A technology of aluminum hydroxide and dehydrating agent, which is applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of large foam and affect production, and achieve the effect of wide application, strong effect and small amount of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

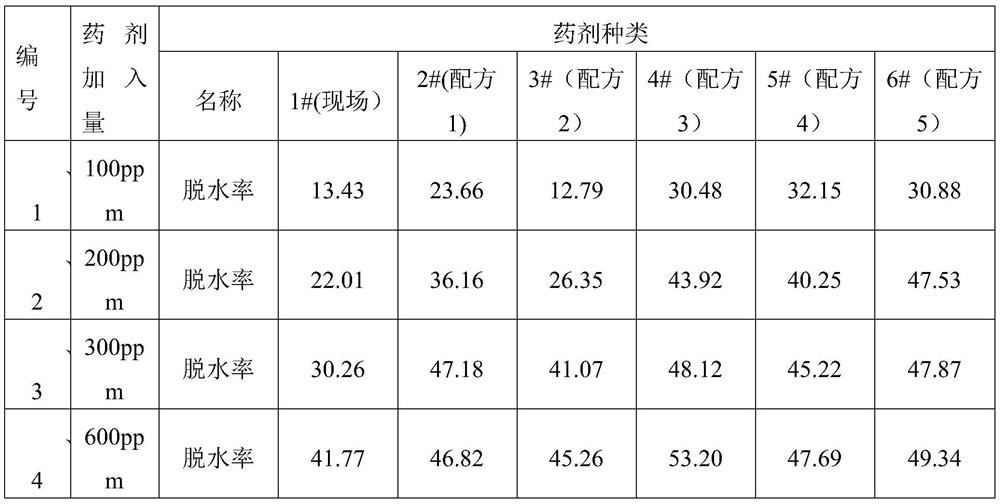

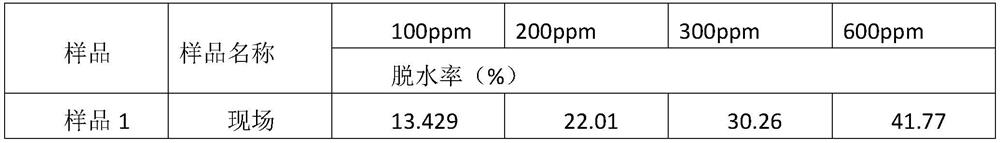

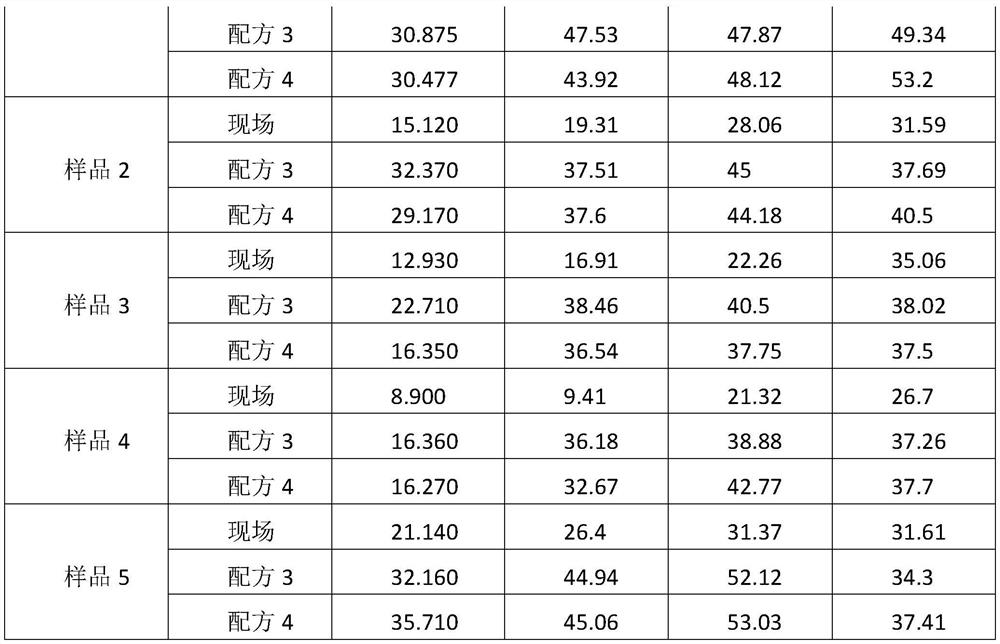

Examples

Embodiment 1

[0026] A kind of dehydrating agent for aluminum hydroxide, its composition comprises by weight percentage: nonionic surfactant: fatty alcohol polyoxyethylene ether (EO9) 7%, zwitterionic surfactant: dodecyl dimethyl betaine 4%, anionic surfactant: sodium lauryl sulfate, sodium dodecylbenzenesulfonate 11%, auxiliary agent: silicone defoamer 1%, organic amine salt active agent: dodecyl trimethyl Ammonium chloride 2%, water: 75%.

[0027] A kind of preparation method of aluminum hydroxide dehydrating agent is as follows:

[0028] According to the above ratio, heat the required water to 50°C, then add dodecyltrimethylammonium chloride, stir until the organic ammonium salt compound is completely dissolved, and then add fatty alcohol polyoxyethylene ether (EO9) in sequence , dodecyl dimethyl betaine, sodium lauryl sulfate, sodium dodecyl benzene sulfonate, organic silicon defoamer, etc., to obtain the dehydrating agent for aluminum hydroxide, called Take a certain amount of dehydr...

Embodiment 2

[0030] A kind of dehydrating agent for aluminum hydroxide, its composition comprises by weight percentage: nonionic surfactant: polyoxyethylene ether polyoxypropylene ether block polymer 14%, zwitterionic surfactant: hexadecylsulfonic acid Base betaine 2%, anionic surfactant: sodium fatty alcohol polyoxyethylene ether sulfonate 7%, auxiliary agent: silicone defoamer 1%, organic amine salt active agent: dodecyltrimethylammonium chloride 1%, water: 75%.

[0031] A kind of preparation method of aluminum hydroxide dehydrating agent is as follows:

[0032] According to the above ratio, heat the required water to 50°C, then add dodecyltrimethylammonium chloride, stir until the organic ammonium salt compound is completely dissolved, then add polyoxyethylene ether polyoxypropylene ether embedded Segment polymer, cetyl sulfonate betaine, sodium fatty alcohol polyoxyethylene ether sulfonate, organic silicon defoamer, etc., to obtain the dehydrating agent for aluminum hydroxide. Weighe...

Embodiment 3

[0034] A kind of dehydrating agent for aluminum hydroxide, its composition comprises by weight percent: nonionic surfactant: fatty alcohol polyoxyethylene ether (EO9) 10%, zwitterionic surfactant: dodecyl dimethyl betaine 2%, anionic surfactant: fatty alcohol polyoxyethylene ether sodium sulfate 11%, auxiliary agent: silicone defoamer 1%, organic amine salt active agent: dodecyltrimethylammonium chloride 1%, water : 75%.

[0035] A kind of preparation method of aluminum hydroxide dehydrating agent is as follows:

[0036] According to the above ratio, heat the required water to 50°C, then add dodecyltrimethylammonium chloride, stir until the organic ammonium salt compound is completely dissolved, and then add fatty alcohol polyoxyethylene ether (EO9) in sequence , lauryl dimethyl betaine, sodium fatty alcohol polyoxyethylene ether sulfate, silicone defoamer and other substances, that is, to obtain the dehydrating agent for aluminum hydroxide, combined with the above evaluation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com