Stable suspension system, preparation method thereof and cosmetics

A stable and systematic technology, applied in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of inability to add active ingredients, single cosmetic efficacy, layering, etc., and achieve rich applicability, good tolerance, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

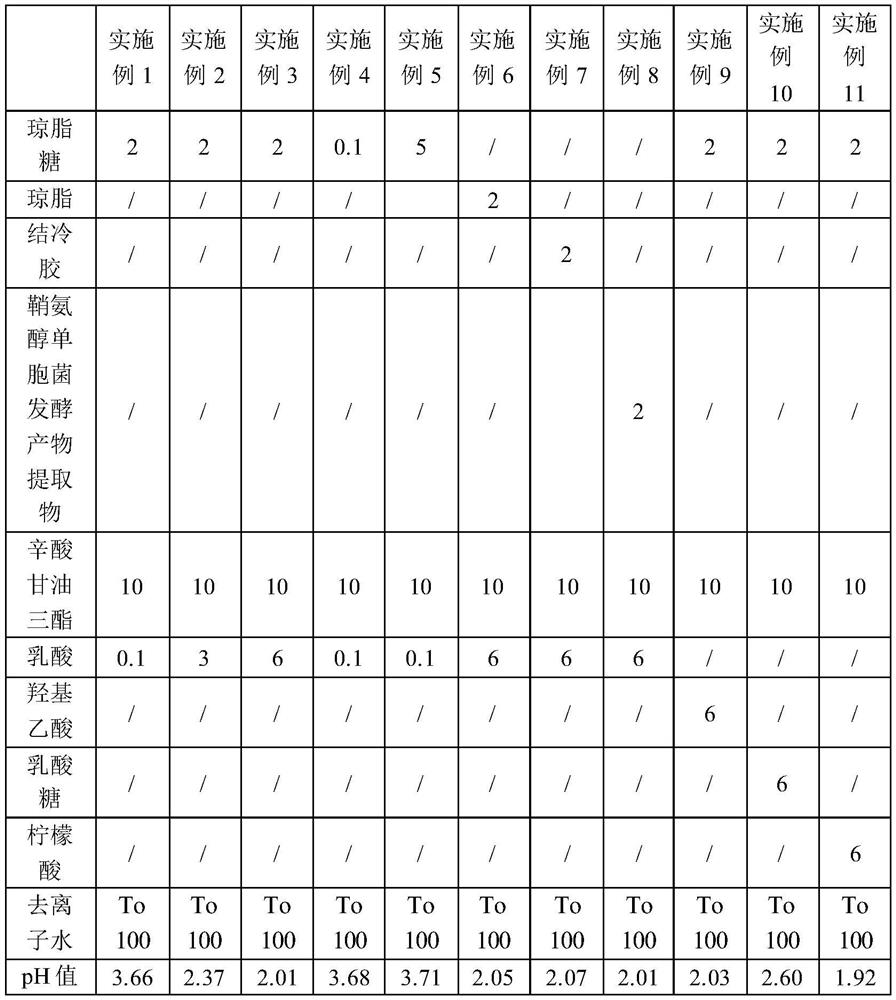

Examples

preparation example Construction

[0057] The present application also provides a preparation method for the above-mentioned stable suspension system, which specifically includes:

[0058] (1) Stir and mix the thickener and water evenly to form a water phase, in which the water phase solution needs to be heated to 70°C to 90°C (specifically, it can be 70°C, 75°C, 80°C, 85°C, 90°C or 70°C ~90℃), ensure that the thickener and water are fully mixed together;

[0059] (2) Heat the oil to 70°C-90°C (specifically, it can be 70°C, 75°C, 80°C, 85°C, 90°C or any value between 70°C-90°C), then mix it with the water phase solution, put Homogenize in a homogenizer to form an emulsion;

[0060] (3) When the temperature of the above-mentioned emulsion is lowered to less than or equal to 50°C, then add at least one of the acidic substance and the ionic substance into the emulsion, and continue homogenizing in a homogenizer to obtain a stable suspension system.

[0061] In one embodiment, the stable suspension system also in...

Embodiment 1

[0069] This embodiment provides a stable suspension system, which includes 0.1% lactic acid, 2% agarose, 10% caprylic triglyceride, and water as the balance, assuming that the total mass of the stable suspension system is 100%.

[0070] The specific preparation method is as follows: weigh 87.9g of water, add 2g of agarose, put it into a water bath and heat it to 80°C, stir evenly to form a water phase; heat 10g of caprylic triglyceride to 80°C to form an oil phase; Mix it with the oil phase and put it into a homogenizer for homogenization to obtain an emulsion, continue stirring until the temperature drops to 40°C, add 0.1g of lactic acid to the emulsion, and continue homogenizing to obtain a stable suspension system.

Embodiment 2

[0072] With embodiment 1, difference is that the consumption of lactic acid is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com