Material management system and management method

A technology for managing systems and materials, applied in logistics, data processing applications, instruments, etc., can solve problems such as economic losses, increased enterprise workload, material expiration, etc., to achieve the management effect of improving quality, management quality and operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments. This description is only an explanation and description of the technical solution of the present invention, and is not regarded as the protection scope of the present invention.

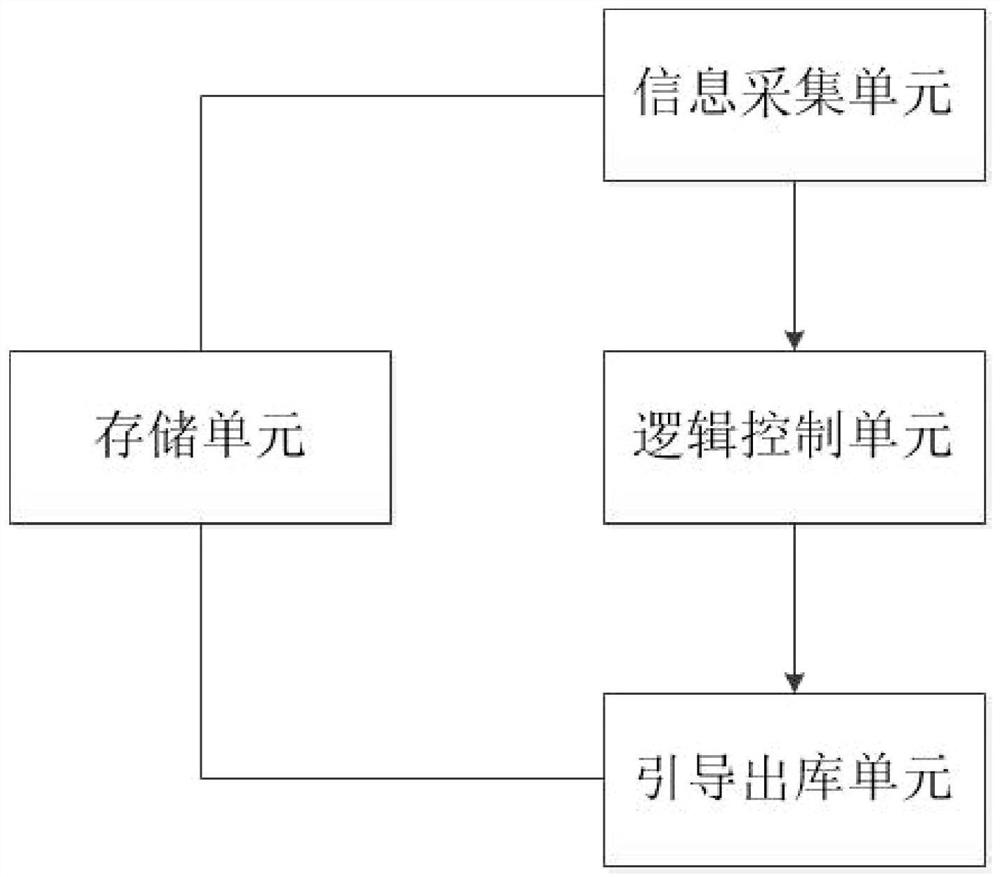

[0032] The invention relates to a material management system, which includes an information collection unit, a logic control unit, a warehouse-out guiding unit, and a storage unit;

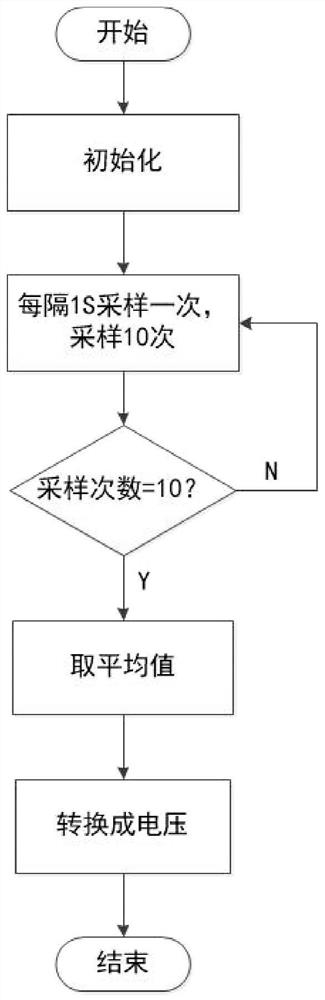

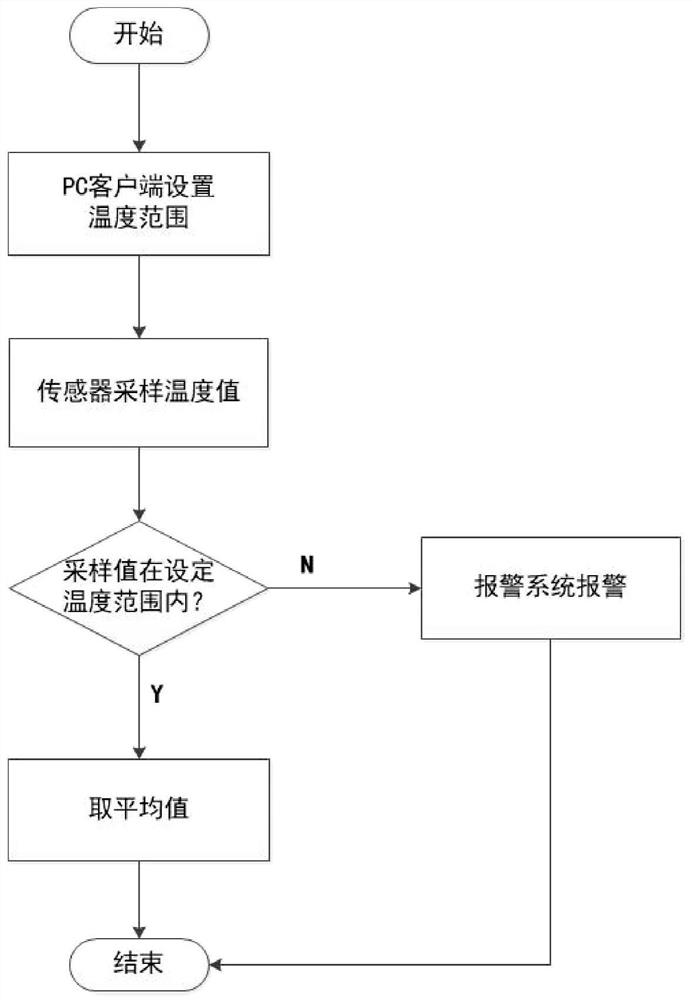

[0033] The information collection unit is mainly used to collect material information and the temperature and humidity of the external environment and upload the collected data information to the storage unit;

[0034] The storage unit stores and updates according to the uploaded data to ensure real-time monitoring of material data;

[0035] The logic control unit receives and processes the data information sent by the information collection unit, and screens out the materials that match the shelf life of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com