Integrated laser damage surface observation system

An observation system, laser damage technology, applied in the direction of optical testing flaws/defects, measuring devices, material analysis through optical means, etc., to achieve the effect of improving focusing imaging ability and resolution, simple device structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

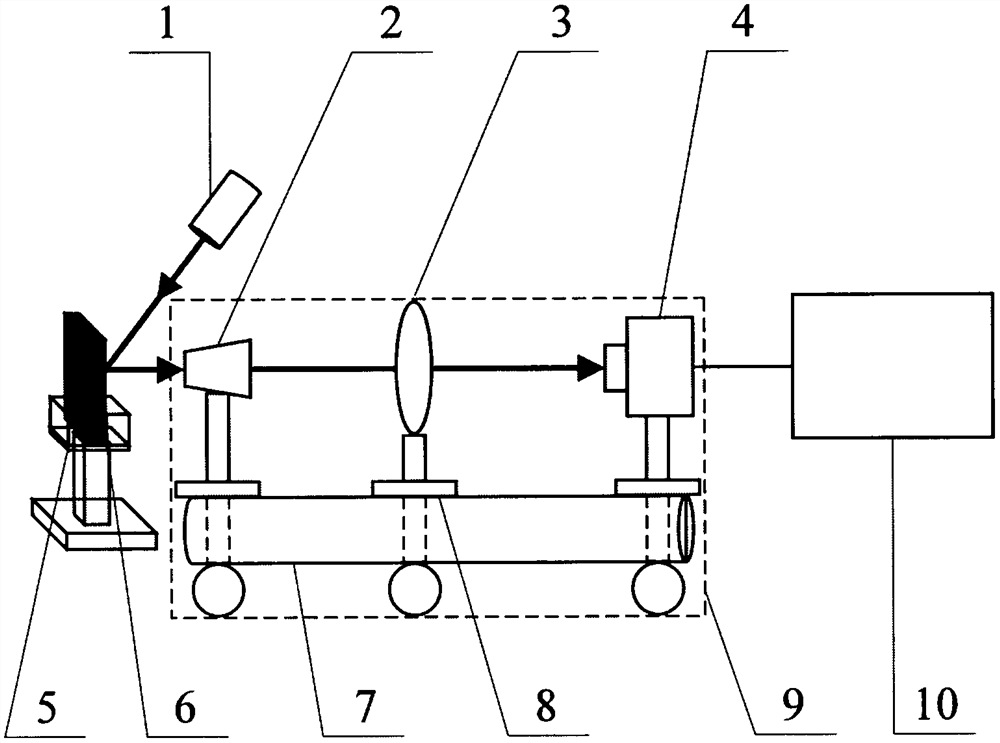

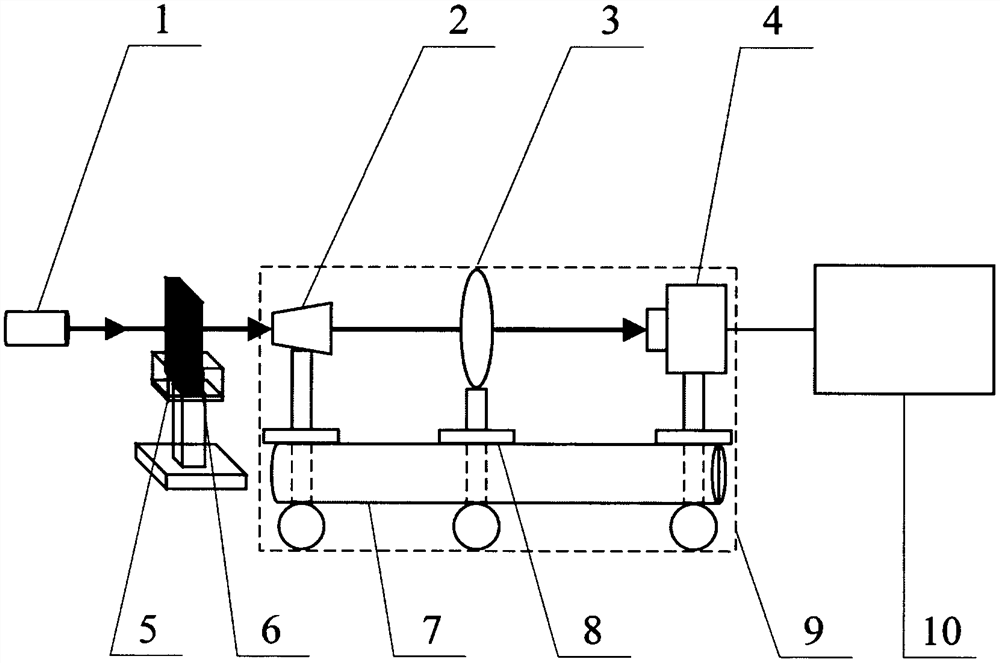

[0032] like figure 1 As shown, an integrated laser damage surface observation system, including: LED light source-1, microscope objective lens-2, tube lens-3, CCD camera-4, clamping device-5, silicon wafer damaged by laser- 6. Lifting column-7, gear slide-8, coaxial system-9, computer-10.

[0033] Among them: the silicon wafer damaged by the laser-6 is fixed by the clamping device-5, the observation illumination light source is emitted from the LED light source-1, and enters the microscope objective lens-2 after being reflected by the surface of the silicon wafer; the microscope objective lens-2, tubular The lens-3 and the CCD camera-4 form a microscopic observation system, which is placed on the coaxial system-9 to ensure that the incident light is coaxial. The coaxial system-9 is composed of a lifting cylinder-7 and a gear slide-8, and can be horizontal or vertical Move straight; the damaged surface of the silicon wafer is imaged by the CCD camera-4 of the microscopic obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com