Oil particle multiple information detection method and application thereof

A technology of information detection and particles, applied in individual particle analysis, particle and sedimentation analysis, measuring devices, etc., can solve the problems of incomplete detection information, inability to detect particle components, inability to distinguish particle metal or non-metallic substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

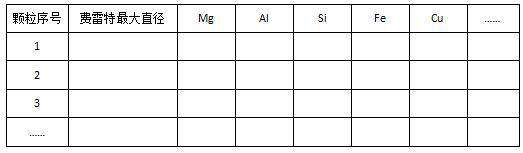

[0027] This embodiment discloses a method for detecting multiple information of oil particles, such as figure 1 The shown includes sampling steps, sample preparation steps, detection steps, and data processing steps; it is characterized in that, the detection step adopts a scanning electron microscope and an energy spectrometer integrated with an intelligent particle research module to detect the oil, and obtains particle types, Particle number, particle size range, particle serial number, the proportion of main elements contained in a single particle, and any one or more particle information data in the Feret maximum diameter of a single particle; the data processing steps include integrating the detected particles information data;

[0028] The particle category includes iron-rich particles, copper-rich particles, zinc-rich particles, colloidal particles, and sand;

[0029] The number of particles includes the number of particles under each particle category and the total n...

Embodiment 2

[0044] This embodiment is based on the multiple information detection method of oil particles disclosed in Embodiment 1, and specifically illustrates the application of the detection method in hydraulic pump failure prediction.

[0045]In modern industry, especially in the aviation industry, the hydraulic pump is one of the indispensable components, and the wear of the hydraulic pump is the most important factor affecting its service life. The wear of the hydraulic pump is usually caused by the friction and wear of the friction pair of the pump or the fatigue and shedding of the internal metal material. If the wear of the hydraulic pump is light, the pressure of the pump will be reduced, the temperature will be increased, and the flow rate will be reduced, and if it is severe, the entire hydraulic pump will fail. Therefore, by detecting the wear of the hydraulic pump, the early failure of the hydraulic pump can be identified, so as to perform condition-based maintenance and im...

Embodiment 3

[0068] This embodiment is based on the multiple information detection method of oil particles disclosed in Embodiment 1, and specifically illustrates the application of the detection method in the detection of the filter screen in the oil filter.

[0069] In the hydraulic system of modern industry, due to the composition of the system or the intrusion outside the system, it is inevitable that pollutants will appear in the hydraulic system. These pollutants may be particles, colloids or other substances. Pollutants will not only cause a certain degree of wear and tear on related equipment, but also block small holes and block valve cores. The use of oil filter is the most effective method to control the cleanliness of hydraulic oil. Under this method, the pollutants in the hydraulic system will accumulate on the oil filter with the oil and form a filter. Through the detection of the filter in the oil filter , not only can understand the types and sources of pollutants in the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com