Fatigue test device of parking brake for forklift

A parking brake, fatigue test technology, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

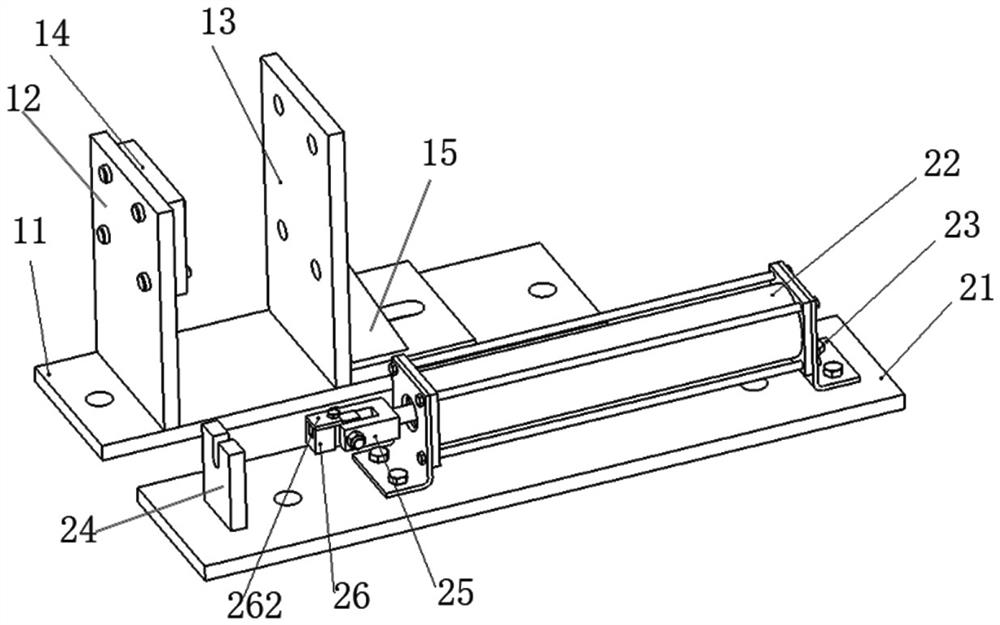

[0031] See figure 1 , a fatigue test device for a parking brake of a forklift, comprising a brake fixing mechanism and a cylinder mechanism;

[0032] The brake fixing mechanism includes a fixed base plate 11, a brake mounting plate 12 and a hub mounting plate 13, and the brake mounting plate 12 and the hub mounting plate 13 are arranged upright and parallel at intervals on the fixed base plate 11;

[0033] The cylinder mechanism includes a cylinder bottom plate 21 and a cylinder 22, and the cylinder 22 is horizontally fixed above the cylinder bottom plate 21 through a pair of L-shaped support plates 23;

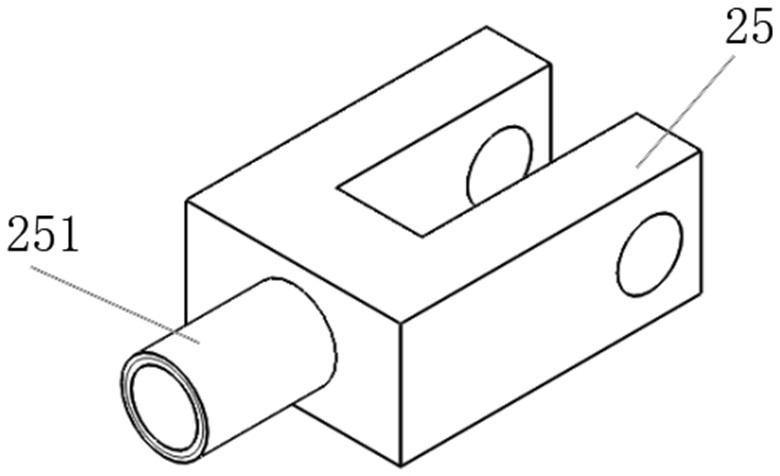

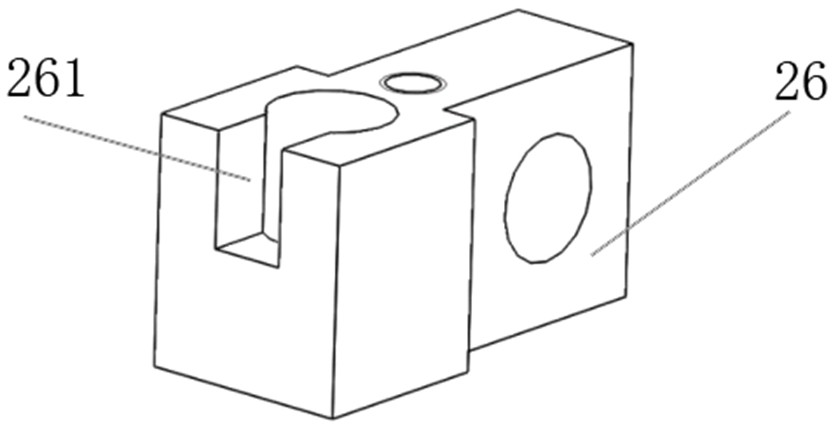

[0034] One end of the cable 31 is fixedly connected to the protruding end of the piston rod through the connecting seat, and a section of the cable corresponding to the cylinder bottom plate 21 is horizontally arranged above the cylinder bottom plate 21 through the support plate 24, and arranged coaxially with the piston rod;

[0035] The parking brake 32 and the wheel hub 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com