Heat dissipation system, box body and installation method

A heat dissipation system and cabinet technology, applied in household refrigeration equipment, lighting and heating equipment, defrosting, etc., can solve problems such as short circuit of air inlet and air outlet, limited size and length of condenser, and limited heat dissipation area, etc., to achieve Improve the heat dissipation effect, increase the size, and increase the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

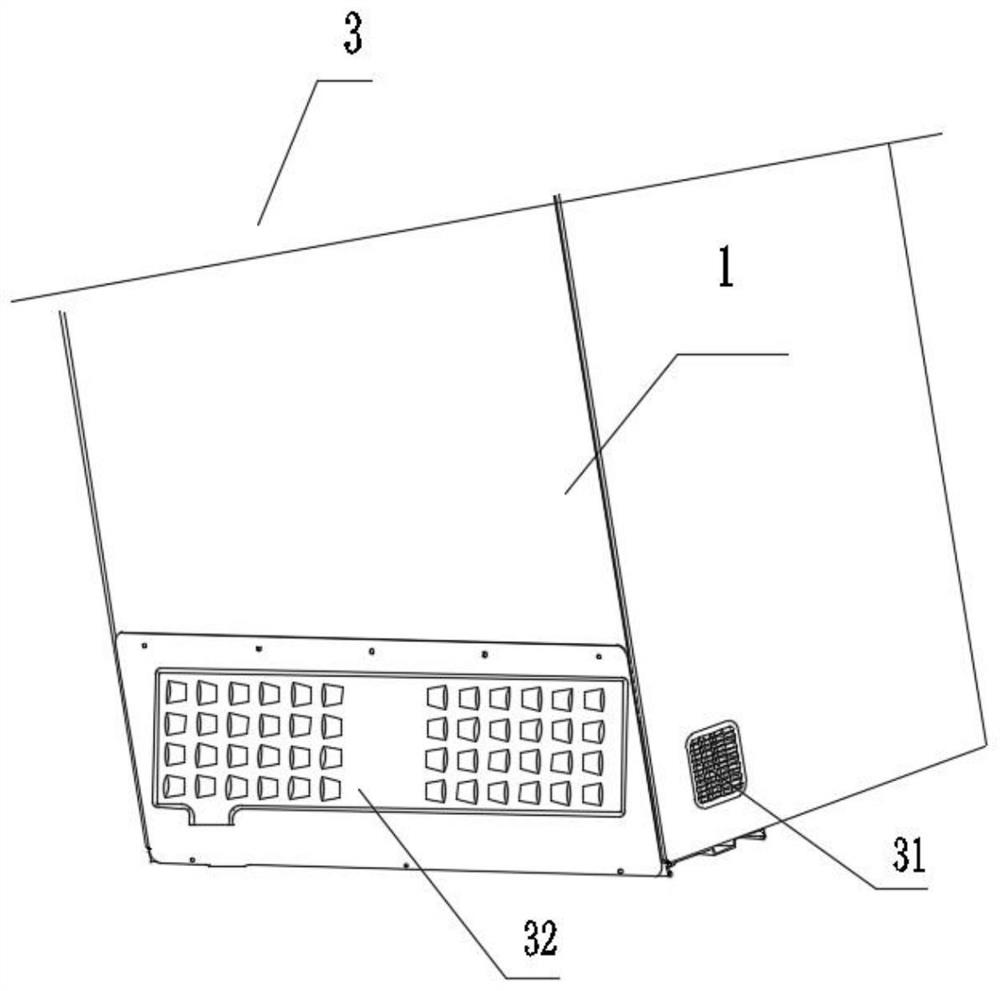

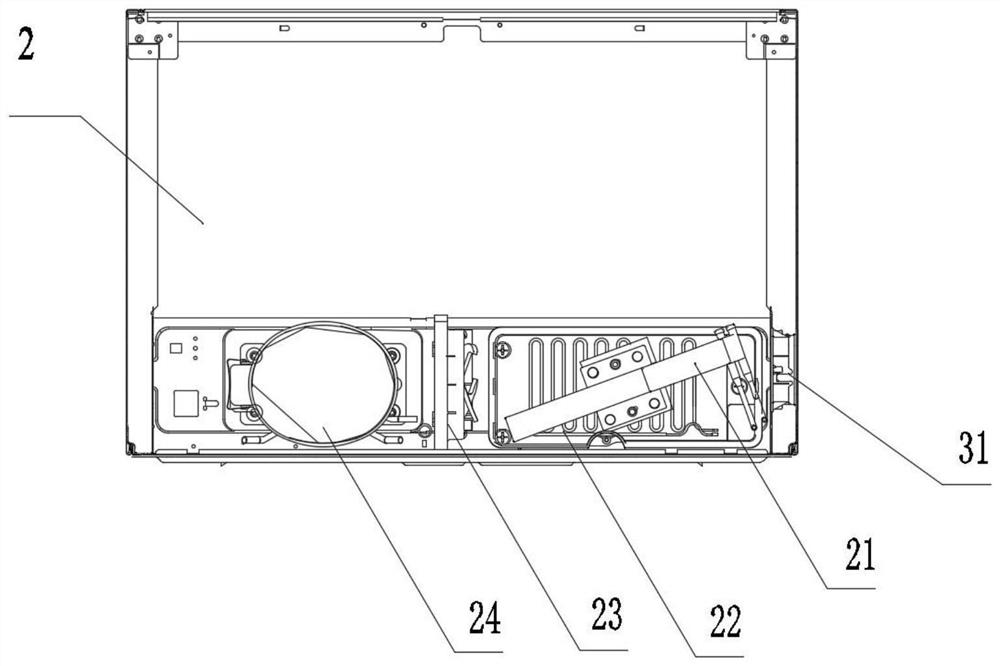

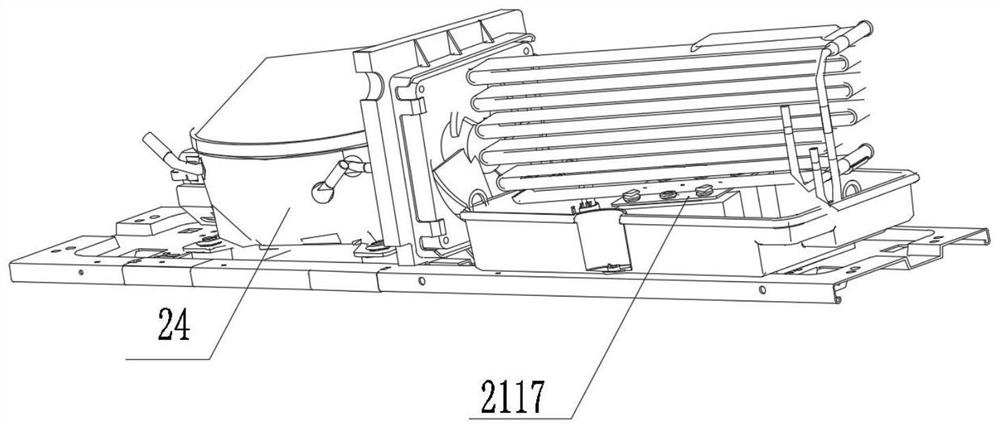

[0049] see Figure 1-2 As shown, the present invention is a heat dissipation system, including an air duct system 3 and a heat dissipation module 2 installed on the bottom plate of the box body 4; the heat dissipation module 2 includes a condenser assembly 21, a water tray 22, a fan assembly 23 and a compressor 24 The condenser assembly 21 includes a main condenser 211 and a sub-condenser 212 connected with the main condenser 211; defrosting water to achieve the purpose of rapid heat dissipation; the water receiving tray 22 is an open box-shaped container, and a mounting platform 221 for installing the main condenser 211 is arranged at the middle position inside the water receiving tray 22; The water tray 22 forms an included angle a in the horizontal direction, and makes the main condenser 211 form an included angle a corresponding to the air inlet direction of the air duct system 3 after assembly. The main condenser 211 and the fan 231 are installed at an included angle, whi...

Embodiment 2

[0055] On the basis of Example 1, as Figure 11-13 As shown, the air channel assembly 31 includes an air channel box 311 and an air channel cover 312; the air channel box 311 includes a channel main body 3111 and a fixing part 3112, and a buckle hole 3110 is opened on the side of the air channel box 311; the channel main body 3111 is The main air inlet channel is provided with a through-hole structure 31111 for ventilation; the fixed part 3112 is arranged around the channel main body 3111 and is provided with an installation hole E31121; the air channel cover 312 includes a ventilation body 3121 and a matching part 3122; Ventilation holes 31211 with a grid structure are provided; the matching part 3122 includes a claw body 31221 and an extension body 31222 that are engaged with the buckle hole 3110 and an extension body 31222. .

[0056] Such as Figure 11-14 As shown, the rear cover 32 includes an air inlet 321 arranged on the right side of the fan assembly 23 and an air ou...

Embodiment 3

[0058] On the basis of the first embodiment, the present application also provides a box, including a box body 1 and a box shell 6; the box body 1 is equipped with the above-mentioned heat dissipation system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com