Visible light curing coating and preparation method thereof

A technology for curing coatings and visible light, applied in the direction of coatings, etc., can solve problems such as development and application in the initial stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A: Take the mixture of pentaerythritol tetraacrylate, propylene glycol methyl ether acetate and higher alcohol fatty acid ester, add dye Alexa Fluor 488 to it under dark conditions, stir at 15°C for 3 hours, and the stirring speed is 300r / min, Obtain acrylate mixture;

[0043] B: Take 1,4-cyclohexanedimethanol divinyl ether compound, add 4-dimethylaminobenzoic acid ethyl ester and 2,4,6-tris(trichloromethyl)-1 , the mixture of 3,5-triazine was stirred at 15°C for 3h at a stirring speed of 300r / min to obtain a mixture of vinyl ethers;

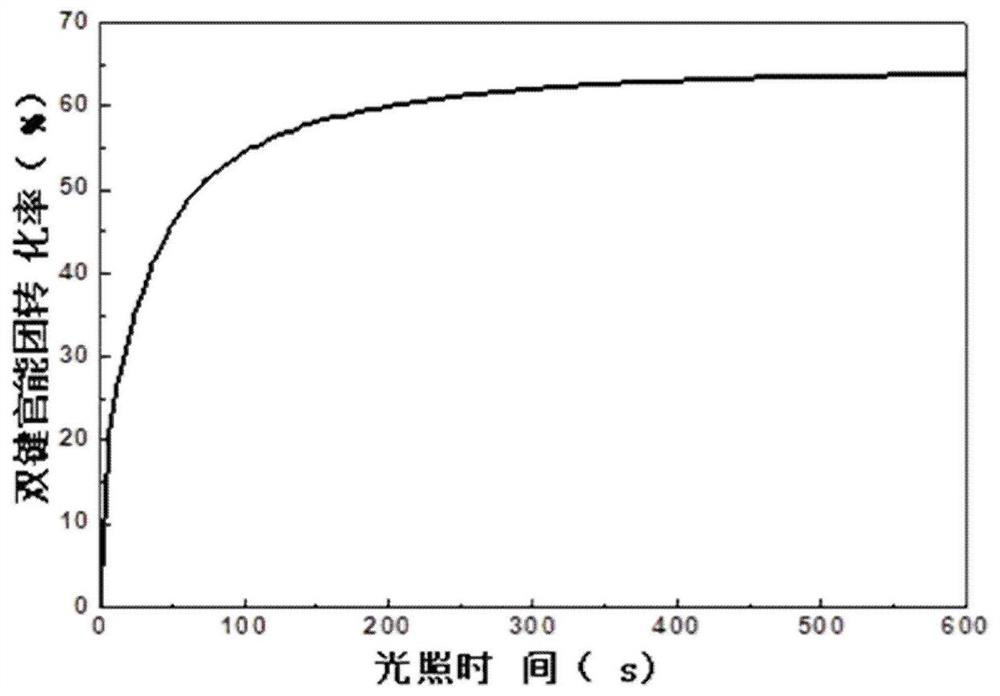

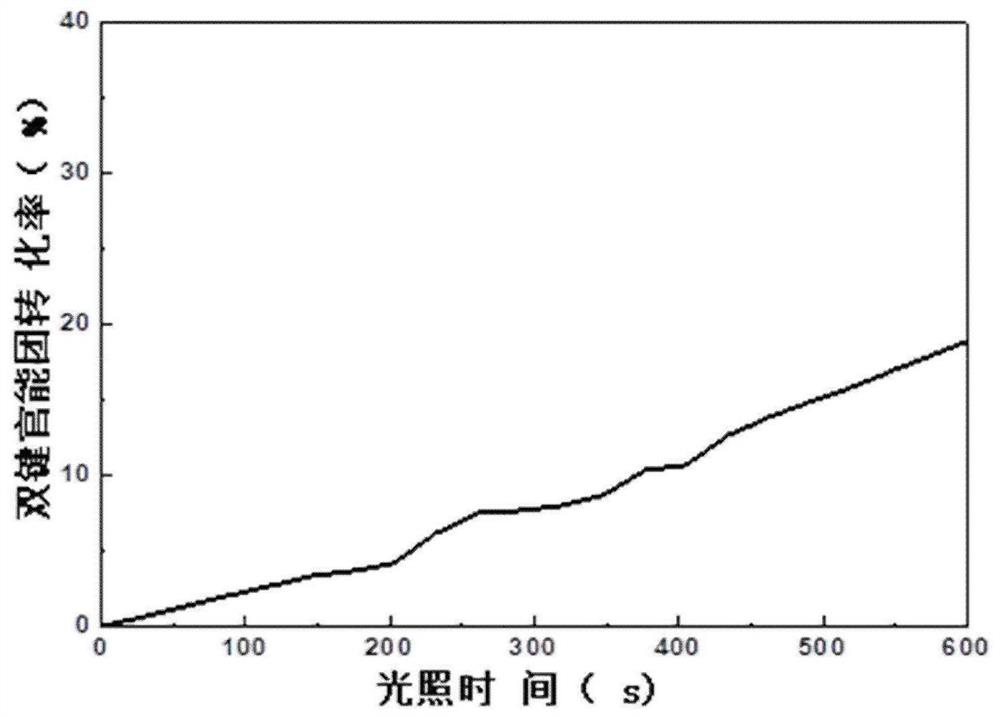

[0044] C: At 15°C, irradiate the acrylate mixture in step A and the vinyl ether mixture in step B through LED for 10 minutes, the wavelength is 470nm, and the light intensity is 19.9μW / mm 2 , to obtain visible light-curable coatings.

[0045] Among them, in terms of parts by mass, there are 100 parts of pentaerythritol tetraacrylate and 1,4-cyclohexanedimethanol divinyl ether, 0.01 parts of Alexa Fluor 488, 0.5 parts of ethyl 4-dimethyl...

Embodiment 2

[0048] The specific preparation method refers to Example 1, wherein, in terms of parts by mass, it includes: a total of 100 parts of trimethylolpropane trimethacrylate and 1,4-dicyclohexane dimethyl divinyl ether, Alexa Fluor 532 A total of 0.01 parts, 1.5 parts of triethanolamine, and 1.5 parts of 2-[2-(furan-2-yl)vinyl]-4,6-bis(trichloromethyl)-1,3,5-triazine.

[0049] Wherein, the mass ratio of pentaerythritol tetraacrylate and 1,4-cyclohexanedimethanol divinyl ether compound is 1:1.

Embodiment 3

[0051] The specific preparation method refers to Example 1, wherein, by mass parts, it includes: 100 parts of Ebecryl 600 and 1,4-butanediol vinyl ether, 2 parts of Alexa Fluor 555, 3 parts of triisopropanolamine, 2, 3 parts of 4,6-tris(trichloromethyl)-1,3,5-triazine, 0.05 part of propylene glycol methyl ether acetate, and 0.05 part of propylene glycol methyl ether acetate.

[0052] Wherein, the mass ratio of pentaerythritol tetraacrylate to 1,4-cyclohexanedimethanol divinyl ether compound is 6:4.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap