Knee pad forming device capable of eliminating bubbles for AR equipment

A technology of eliminating air bubbles and forming devices, which is applied in the field of AR equipment, can solve the problems of small grooves that cannot be discharged in time, sponge gaps, and less polyurethane foam colloid, and achieve the effect of eliminating gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

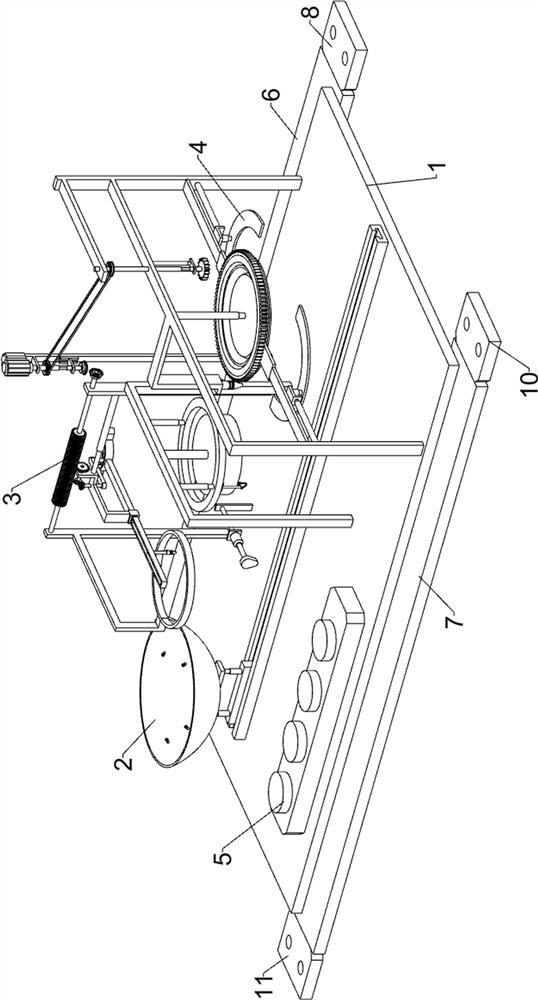

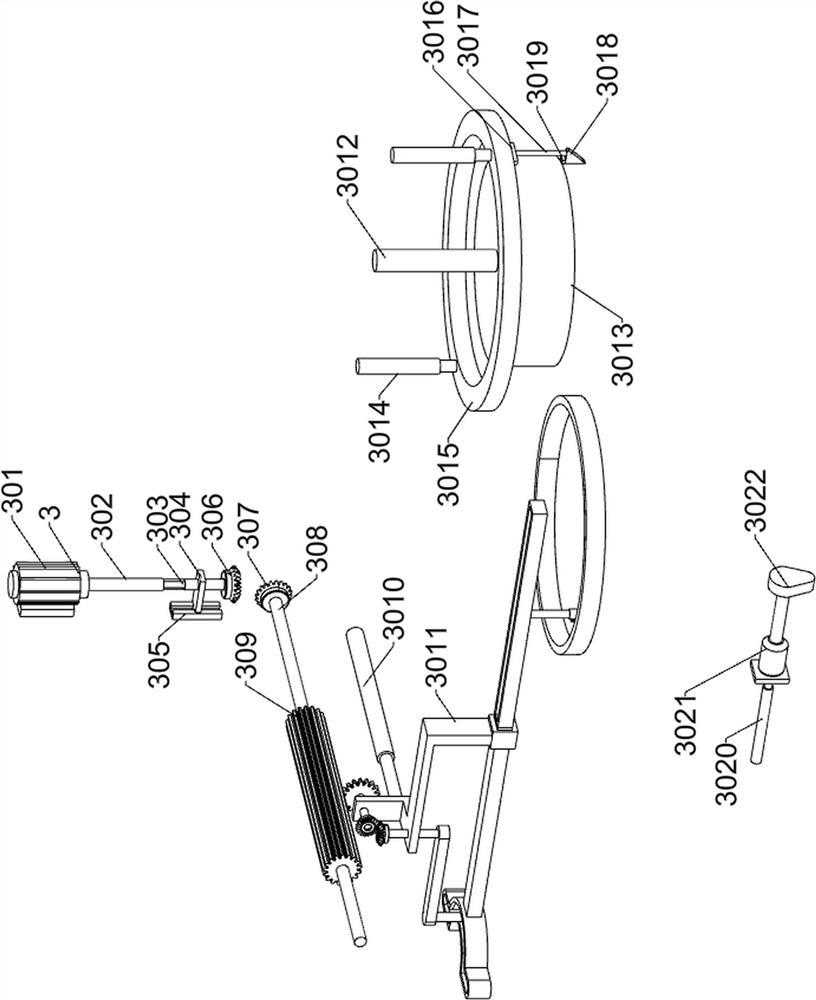

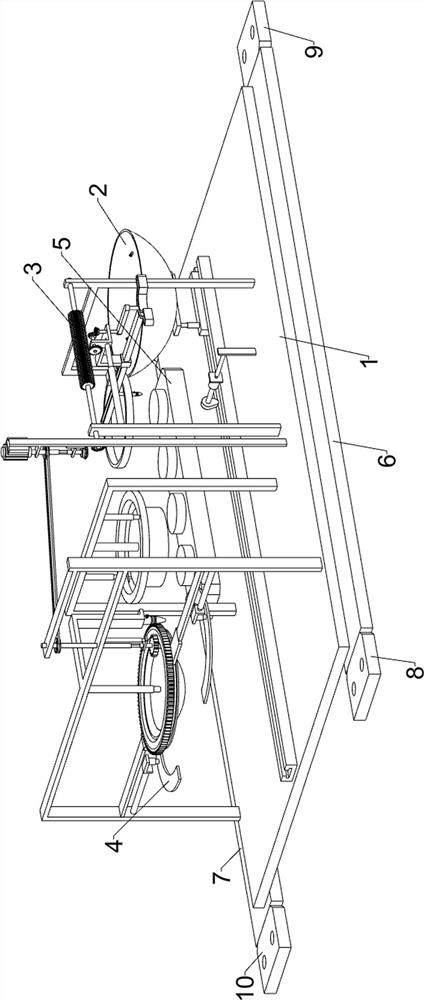

[0030] A knee pad molding device for AR equipment that can eliminate air bubbles, such as Figure 1-11 As shown, it includes a bottom frame 1, a transportation component 2, an upper silicone component 3, a molding component 4, a control button 5, a first bottom plate 6, a second bottom plate 7, a first fixing block 8, a second fixing block 9, a third The fixed block 10 and the fourth fixed block 11; the bottom frame 1 is connected with the transportation component 2; the bottom frame 1 is connected with the upper silicone component 3; the bottom frame 1 is connected with the molding component 4; the bottom frame 1 is fixed with the control button 5 connection; base frame 1 is affixed to the first base plate 6; base frame 1 is affixed to the second base plate 7; the upper silicone component 3 is connected to the molding component 4; the first base plate 6 is affixed to the first fixing block 8 The first bottom plate 6 is fixedly connected to the second fixed block 9; the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com