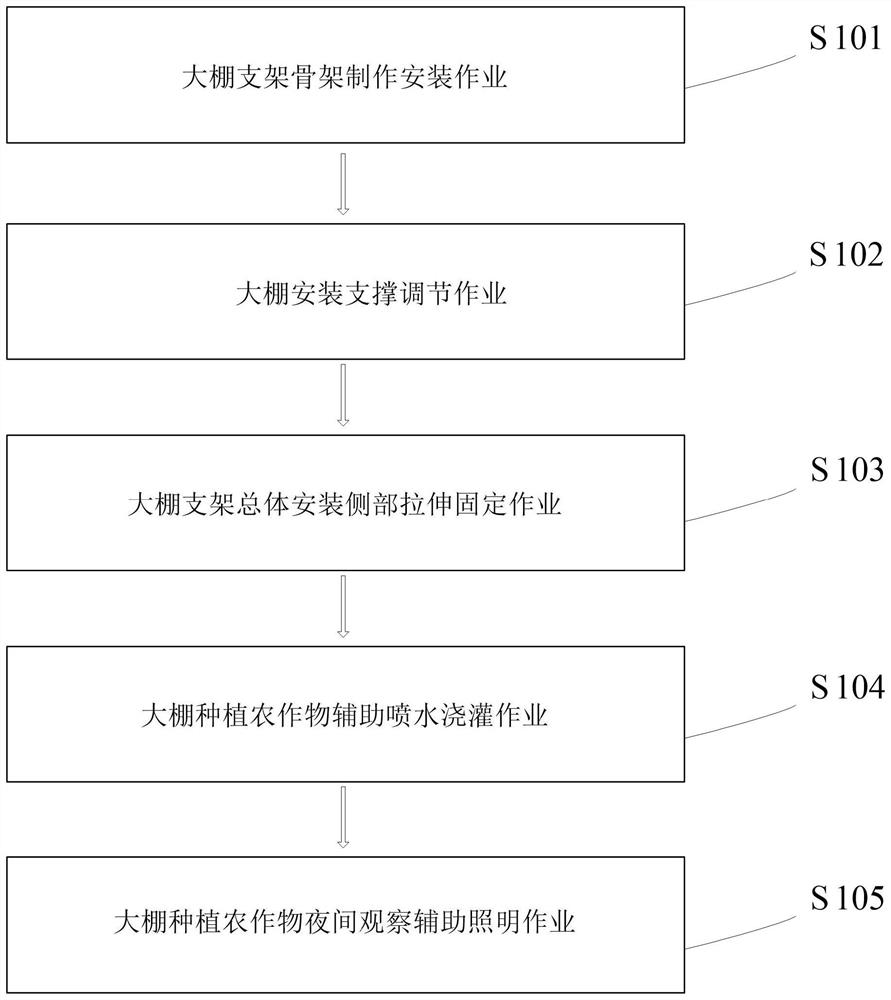

Novel high-strength composite plastic greenhouse support and preparation process thereof

A composite plastic and high-strength technology, applied in the field of greenhouses, can solve the problems of not having the side auxiliary water spray function, not having the night lighting function, and the bottom is not firmly fixed, so as to increase the side watering function and ensure the convenience of installation and fixing , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

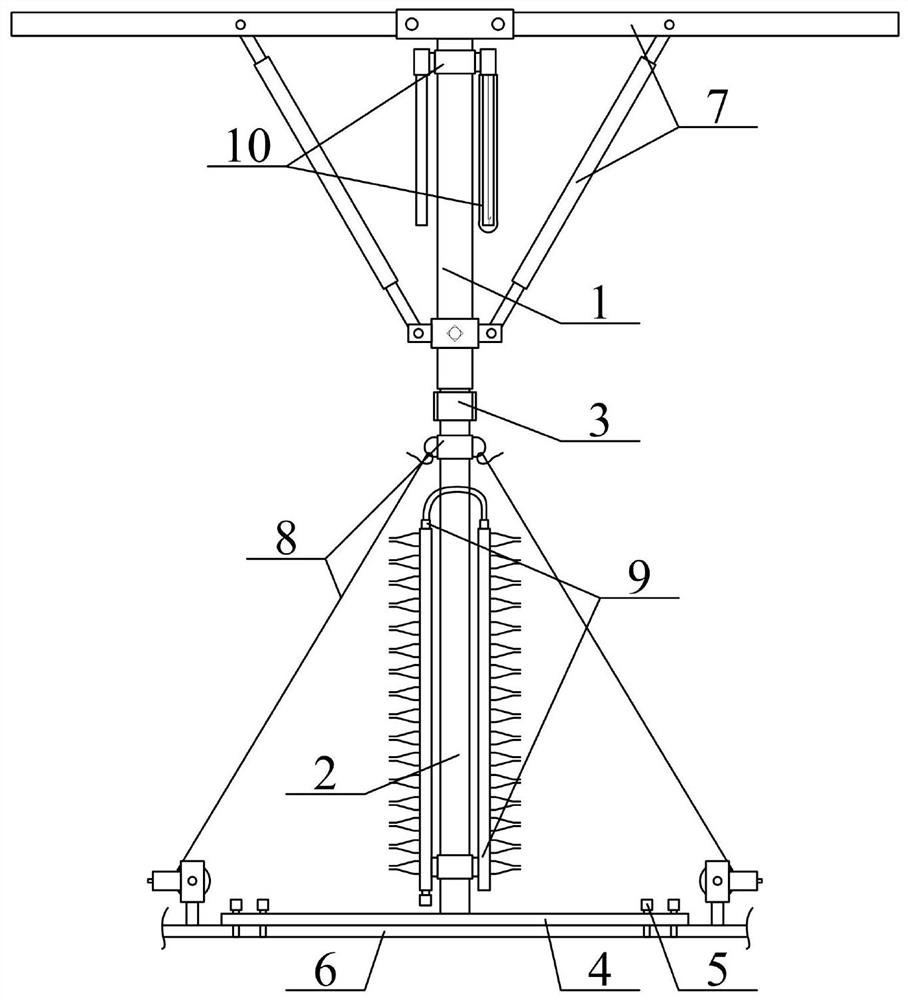

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] In the picture:

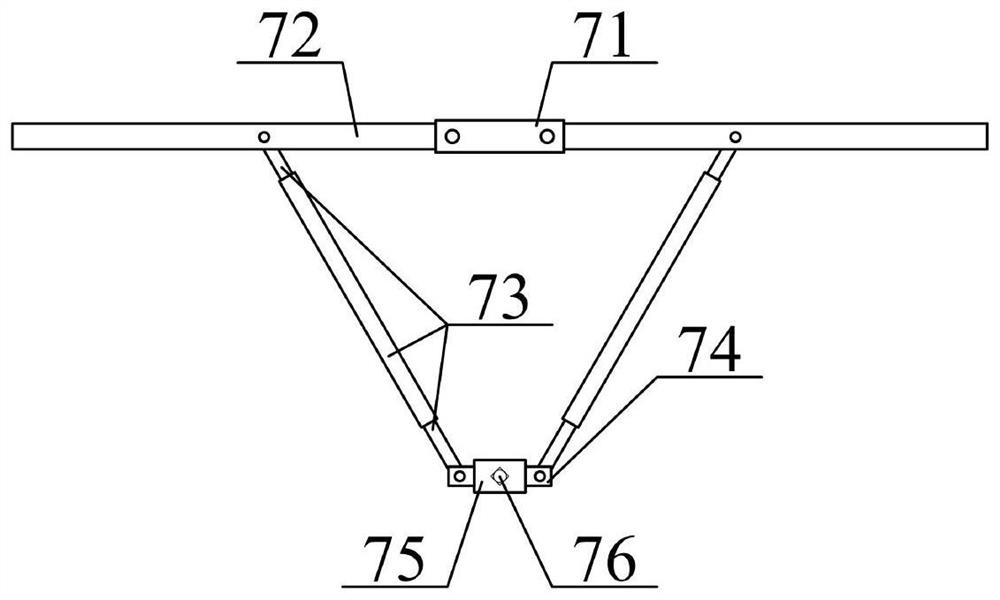

[0032] as attached figure 2 To attach Figure 6 shown

[0033] A new type of high-strength composite plastic greenhouse support, including support pipe 1, support screw 2, lock nut 3, base 4, anchor bolt 5, greenhouse foundation 6, adjustable support rod structure 7, side protection protection pull rope structure 8 , the side auxiliary water spray rotating nozzle structure 9 and the greenhouse night insect-proof auxiliary lighting seat structure 10, the support pipe 1 is longitudinally threaded on the upper outer wall of the support screw 2; the lock nut 3 is threaded on the outer wall of the support screw 2 , and is located at the lower end of the support pipe 1; the longitudinal lower end of the support screw 2 is bolted to the upper middle part of the base 4; the base 4 is installed on the upper part of the greenhouse foundation 6 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com