Phosphating device for manufacturing metal wire rope

A technology of metal wire rope and wire rope, which is applied in the field of wire rope, can solve the problems of inability to carry out further processing, reduce work efficiency, time-consuming and labor-intensive, etc., and achieve the effect of speeding up the conjunctiva, saving time, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

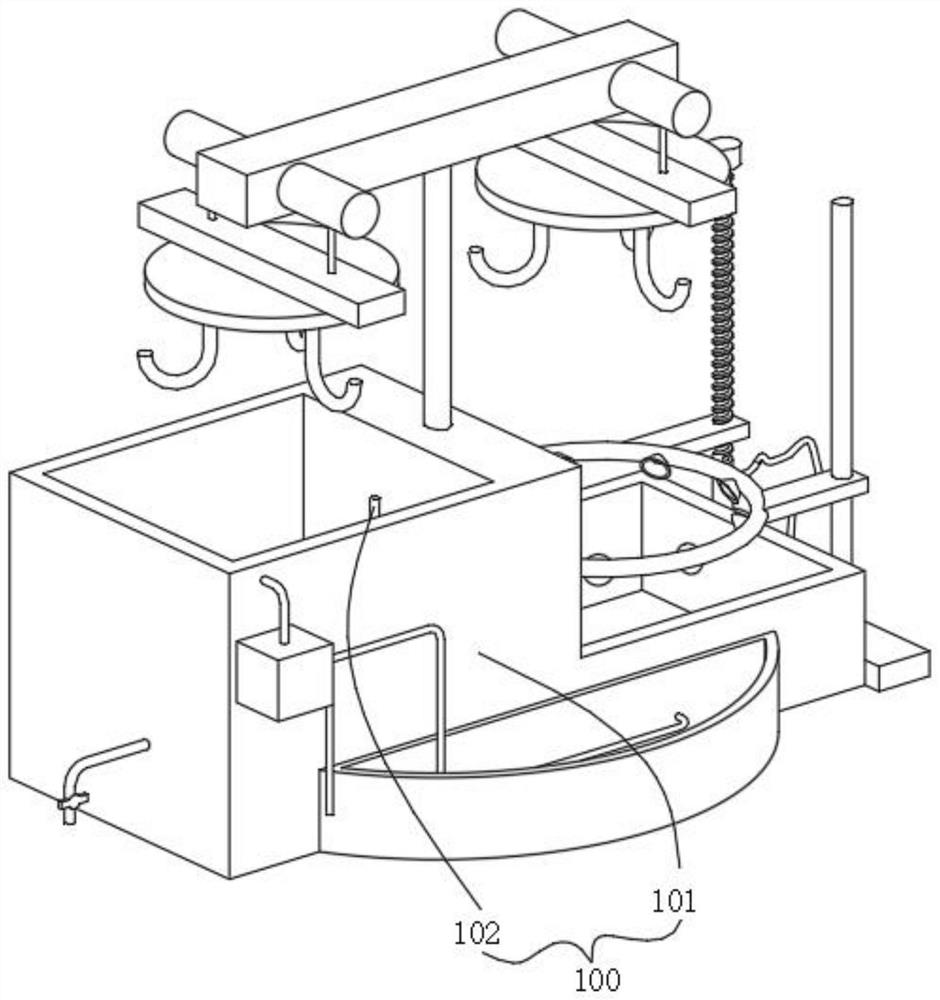

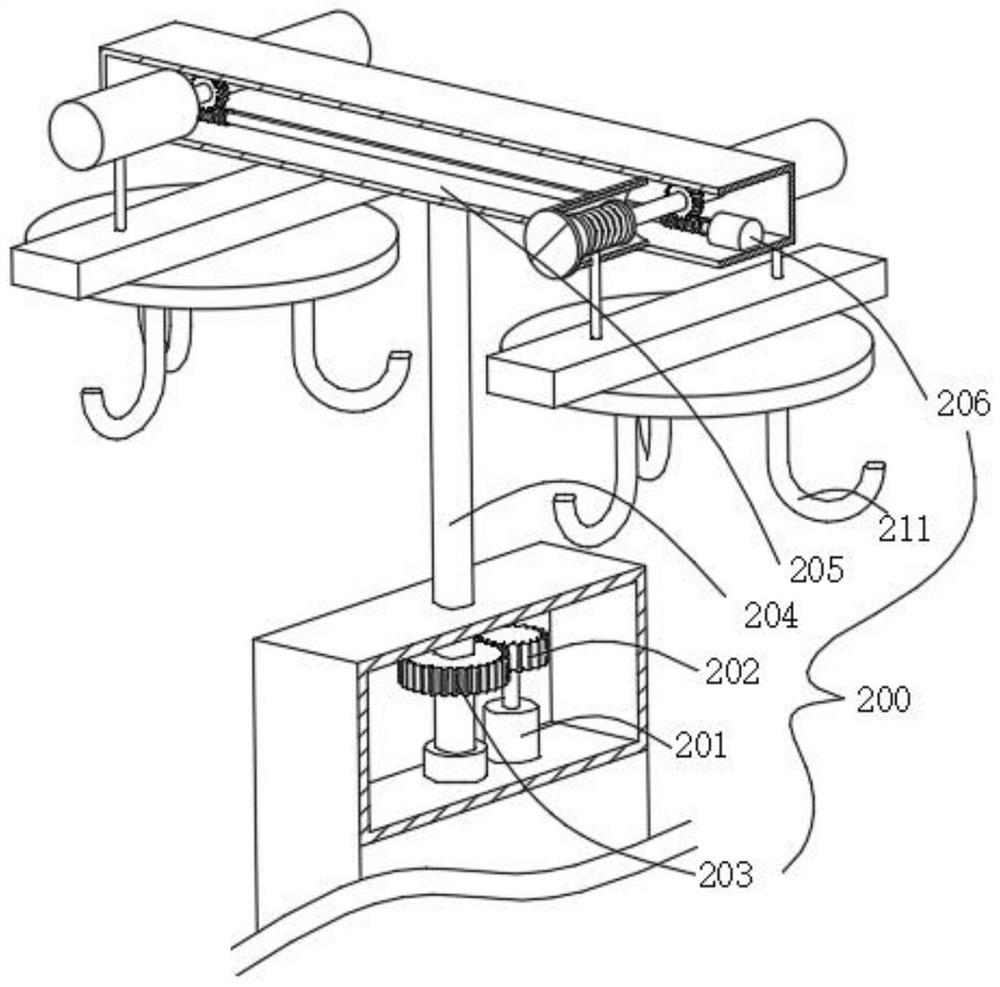

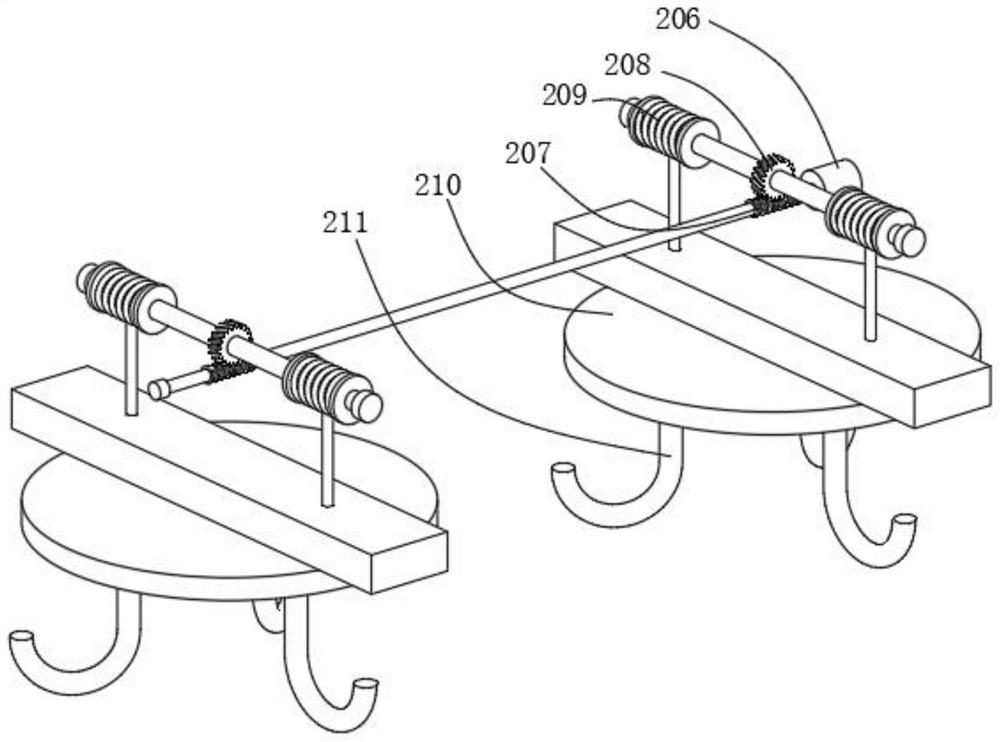

[0049] combine figure 1 , 2 As shown in and 3, the phosphating device for making wire rope provided by the present invention includes a body 100, a liquid immersion mechanism 200, an air-drying mechanism 300, a collection mechanism 400 and a return mechanism 500, and the body 100 includes a phosphating tank 101 and is fixed in The heating tubes 102 on both sides of the phosphating tank 101, the phosphating tank 101 has a built-in cavity, and the immersion mechanism 200 includes a first motor 201 fixed in the cavity, a drive gear 202 fixed to the output end of the first motor 201, The transmission shaft 204 that is rotatably installed in the cavity, the transmission gear 203 that is sleeved on the transmission shaft 204 and meshes with the drive gear 202 for transmission, the housing 205 that is fixed on the top of the transmission shaft 204, and the second housing that is fixed in the housing 205 Second motor 206, the connecting shaft fixedly connected to the output end of th...

Embodiment 2

[0054] combine Figure 4 and 5 As shown, on the basis of Embodiment 1, the air-drying mechanism 300 includes a third motor 301 fixed on one side of the phosphating tank 101, a screw rod 302 fixed on the output end of the third motor 301, a screw rod 302 fixed on the phosphating tank 101- The slide bar on the side, the connecting plate 303 suitable for sliding relative to the screw rod 302 and the sliding bar, the guide ring 304 fixed on the two connecting plates 303, the guide cover fixed on the inside of the guide ring 304 and fixed on the The fan 305 on one side of the phosphating tank 101, the output pipe on the fan 305 is connected to the guide ring 304, the third motor 301 starts to drive the screw 302 to rotate, so that the connecting plate 303 rises or falls, and the guide ring 304 follows the connecting plate 303 Moving, the fan 305 transports the external wind to the guide ring 304 through the pipeline, and then through the guide cover to air-dry the silk rope after ...

Embodiment 3

[0057] combine Figure 4 , 6 , 7, 8 and 9, in the above embodiment, the collection mechanism 400 includes a filter plate 401 fixed on the inner side walls of the phosphating tank 101, a collection box placed in the middle of the bottom wall of the phosphating tank 101 402, a plurality of filter holes opened at the bottom of the collection box 402, and handles fixed on both sides of the collection box 402, the filter plates 401 on both sides are inclined, and the two filter plates 401 are respectively located on both sides of the collection box 402 After the used phosphating solution is discharged, the filter plate 401 filters the impurities in the liquid, and the impurities on the filter plate 401 slide into the collection box 402 to collect the impurities without manual cleaning, saving time and effort.

[0058] Specifically, the collecting mechanism 400 also includes a fourth motor 403 fixed on the phosphating tank 101, a first drive shaft fixed on the output end of the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com