Red mud-based mixed acid chemical conditioner special for deep dewatering of dewatered sludge and use method of red mud-based mixed acid chemical conditioner

A deep dewatering and dewatering sludge technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., to achieve low cost and energy consumption level, solve outlet problems, and avoid technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

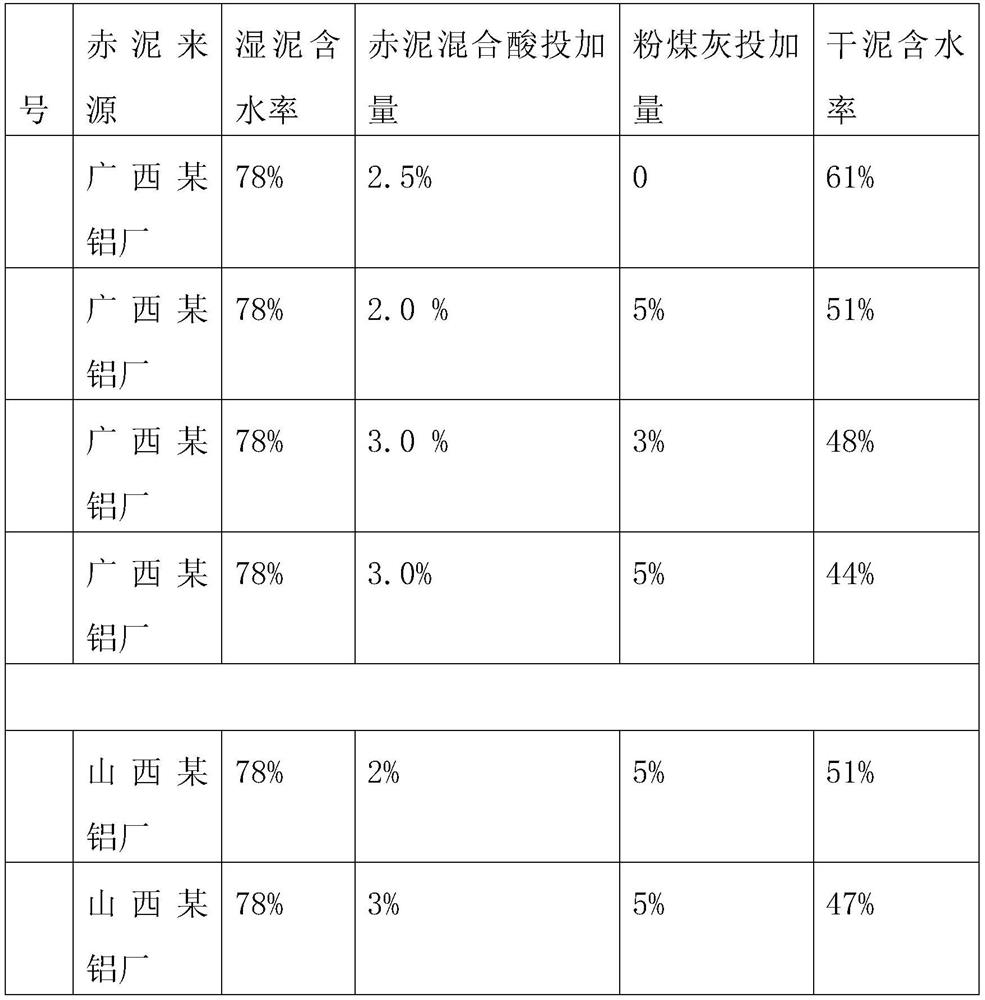

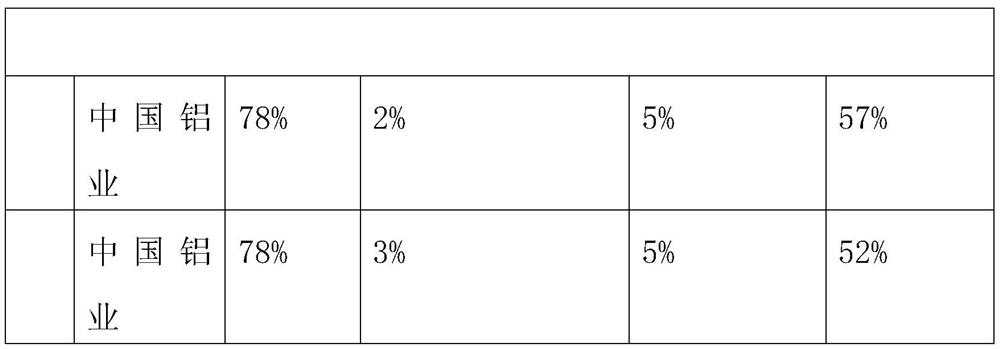

Examples

preparation example Construction

[0036] A preparation method of a red mud-based mixed acid chemical conditioner specially used for deep dehydration of dewatered sludge, specifically comprising the following steps:

[0037] 1) After drying the red mud, use a mechanical ball mill, crush it, and then sieve it for later use;

[0038] 2) Add strong acid to the pulverized red mud, heat it in a water bath, add additives for modification, and obtain a special mixed acid sludge conditioner;

[0039] During specific implementation, the red mud is a red mud sample made by dry stacking method, and the front-end process adopts Bayer method to produce alumina;

[0040]More specifically, in the above step 1), during the mechanical ball milling process, the rotating speed is controlled at 400-450rpm, the ball milling beads account for 40-50% of the volume of the ball milling tank, and the ball milling beads are composed of small ball milling beads, medium ball milling beads and large ball milling beads. Bead composition; th...

Embodiment 1

[0046] The dry red mud stacked in the red mud dry yard of the Bayer process aluminum smelter of Guangxi Xinfa Aluminum and Power Group was used as raw material to prepare the dewatered sludge deep dehydration conditioner:

[0047] After elutriating the dry heap red mud, dry it at 100°C, ball mill and pulverize it through a 200-mesh sieve. Put 10 g of red mud in sulfuric acid / hydrochloric acid mixed acid (50 ml of 3M hydrochloric acid and 50 ml of sulfuric acid), and heat in a water bath at 80°C for 3 hours. Then add 0.5% polydimethyldiallyl ammonium chloride, stir and react for 0.5 hour and set aside. Acid red mud based chemical conditioner, technical grade, was obtained.

Embodiment 2

[0049] The dry red mud piled up in the red mud dry yard of the Bayer process aluminum smelter of Aluminum Corporation of China is used as raw material to prepare the dewatered sludge deep dehydration conditioner:

[0050] After elutriating the dry heap red mud, dry it at 100°C, ball mill and pulverize it through a 200-mesh sieve. Put 10 g of red mud in sulfuric acid / hydrochloric acid mixed acid (50 ml of 1.5M hydrochloric acid and 50 ml of sulfuric acid), and heat in a water bath at 80°C for 5 hours. Then add 0.5% polydimethyldiallyl ammonium chloride, stir and react for 0.5 hour and set aside. Acid red mud based chemical conditioner, technical grade, was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com