Anti-explosion tire

A technology for run-flat tires and wheel hubs, which is applied to road tires, tire parts, vehicle components, etc., can solve problems such as affecting driver control, severe vehicle vibration, and vehicle body inclination, etc., to facilitate operation, improve bearing capacity, increase The effect of forward resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

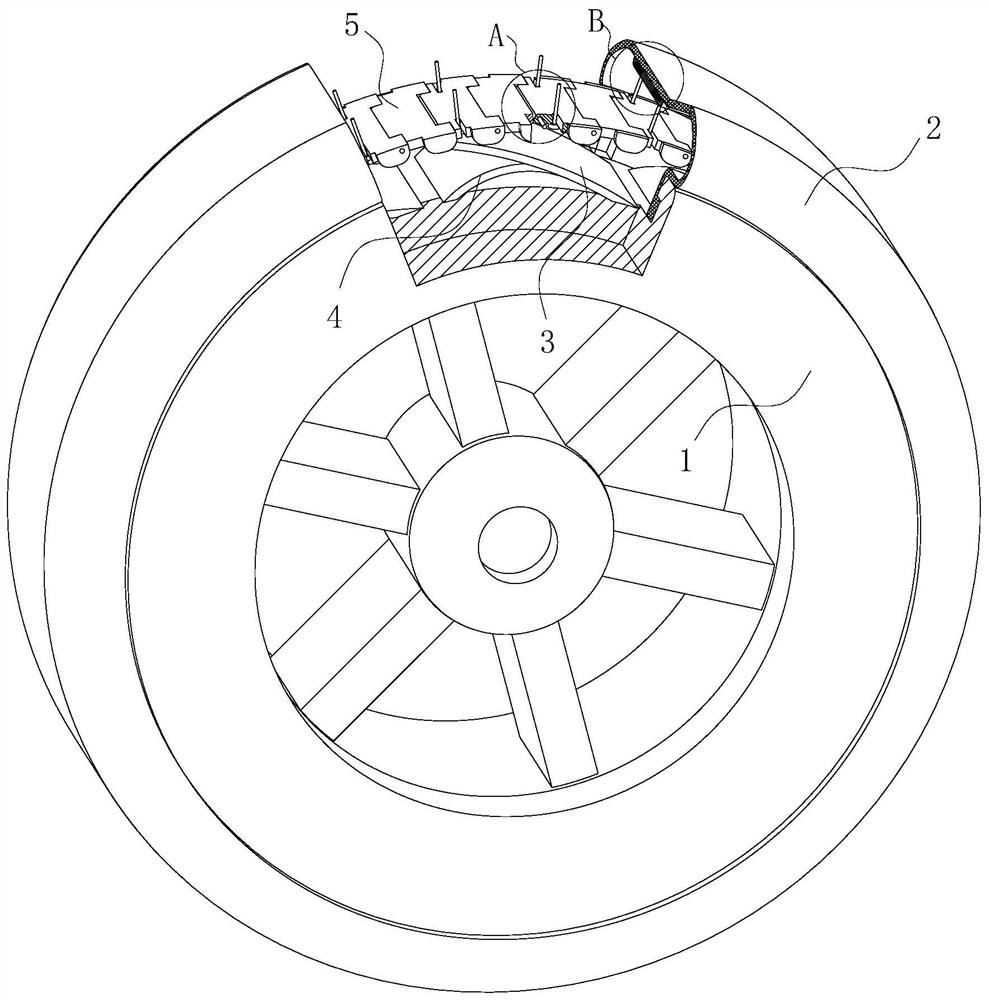

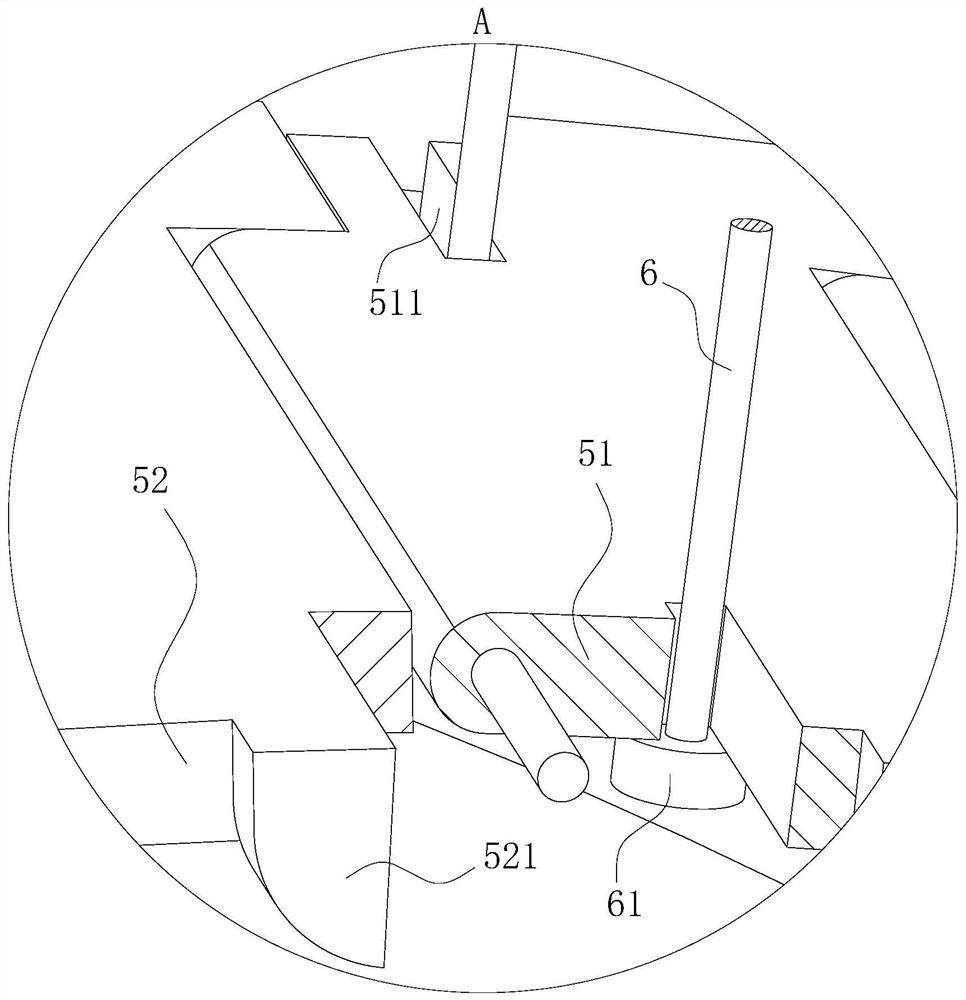

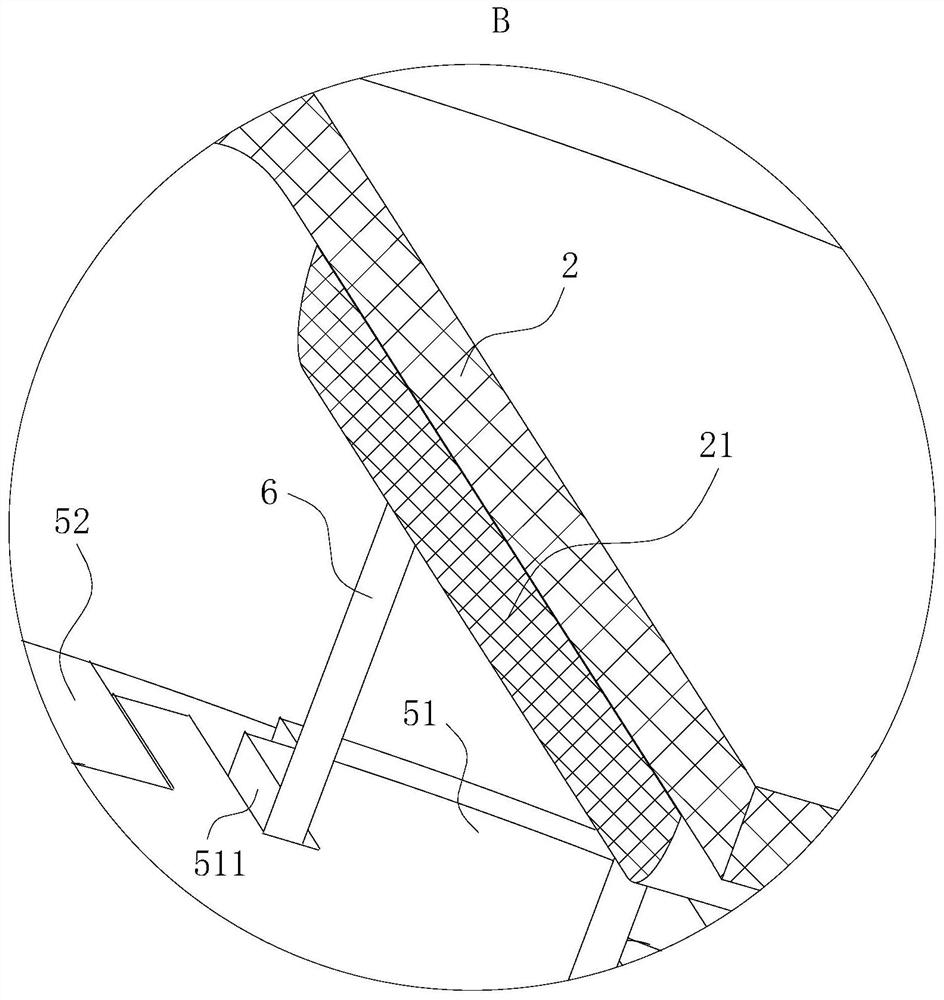

[0029] As an embodiment of the present invention, a chain belt 5 is fixedly installed in the space enclosed by the surface of the outer diameter of the tire 2 and the wheel hub 1; Contact and squeeze the inner diameter surface of the chain belt 5; the chain belt 5 does not contact the tire 2;

[0030] The chain belt 5 is obtained by alternately combining the first chain link 51 and the second chain link 52; the first chain link 51 and the second chain link 52 are hinged; the vertical direction of the second chain link 52 and the hub A rib 521 is fixedly installed on the side of the center line of the wheel hub 1; the rib 521 blocks the movement of the chain belt 5 in the axial direction of the center line of the hub 1;

[0031] When working, when the vehicle is running on poor road conditions and causes large bumps or when the vehicle is heavily loaded, the force on the tire 2 on the wheel is obviously greater than that of the tire 2 when the vehicle is running on a flat road ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com