A multi-directional adjustable composite ultrasonic-assisted EDM spindle

A composite ultrasonic and electric spark technology, applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of no spindle device, etc., and achieve the effect of low price, stable performance, and high electromechanical conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

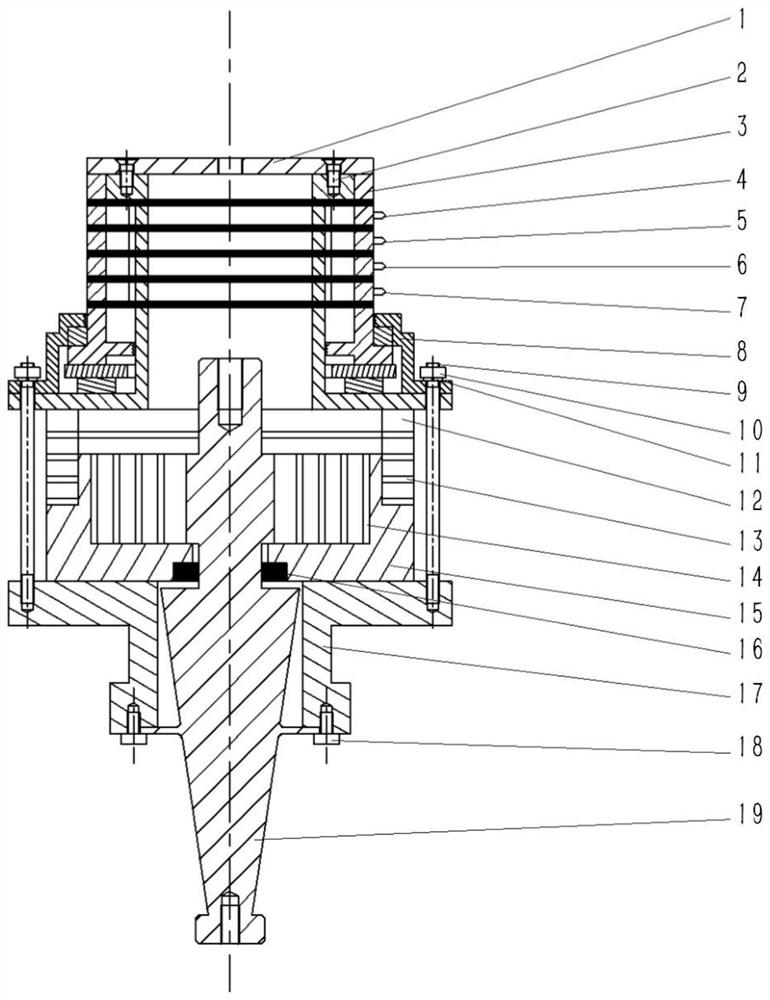

[0028] like Figure 1-3 As shown, this embodiment provides a multi-directional adjustable composite ultrasonic-assisted EDM spindle, including a top cover 1 , an electric slip ring 3 , a thrust sliding bearing 8 , an ultrasonic transducer 12 , a sleeve 17 , and a horn 19 . The top cover 1 is provided with a spiral through hole in the middle, which is used to connect the rotating spindle of the EDM machine; the bottom end face of the top cover 1 is connected with the electric slip ring 3 to transmit the rotating motion of the spindle, and is fixed with a flat-head screw 2; the thrust sliding bearing 8 is sleeved on the bottom of the electric slip ring 3 to bear axial thrust and limit axial movement, wherein the housing of the thrust sliding bearing 8 is in clearance fit with the stator of the electric slip ring 3 . The bottom of the ultrasonic transducer 12 is a limit chuck 15, a circular piezoelectric stack 13 that generates longitudinal vibration is fixed on a card table on t...

Embodiment 2

[0030] This embodiment provides a method for using a multi-directional adjustable composite ultrasonic-assisted spark spindle, which includes longitudinal ultrasonic vibration, longitudinal-torsional composite ultrasonic vibration, horizontal ultrasonic vibration and three-dimensional elliptical ultrasonic vibration.

[0031] 1. Longitudinal ultrasonic vibration: The positive pole of the ultrasonic power supply is connected to pin B, and the negative pole of the ultrasonic power supply is connected to pin A. By adjusting the ultrasonic parameters, the longitudinal ultrasonic vibration is assisted EDM.

[0032] 2. Longitudinal-torsional composite ultrasonic vibration: the positive pole of the ultrasonic power supply is connected to pin B, and the negative pole of the ultrasonic power supply is connected to pin A. By adjusting the ultrasonic parameters, the spindle rotates during processing to realize vertical-torsional composite ultrasonic vibration-assisted EDM.

[0033] 3. Hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com