Diamond cutting tool based on rare earth modified iron-based binder and preparation method thereof

An iron-based binder and rare earth modification technology, which is applied to other manufacturing equipment/tools, engine components, turbines, etc., can solve the problems of poor wettability of diamonds, so as to improve the encasement strength, increase wear resistance, and reduce heat loss. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mixing 30-40 mesh synthetic diamonds with a metal bond in a volume ratio of 1:5 to obtain a mixed powder, the metal bond includes Fe70Cu30 pre-alloyed powder 94.5%, Ni50Cr50 pre-alloyed powder 5.0%, praseodymium 0.5% (mass Fraction);

[0026] (2) after the mixed powder is loaded into the graphite mold, hot-press sintering is performed, the sintering temperature is 960 ° C, the sintering pressure is 13 MPa, and the temperature is kept for 3 minutes to obtain a diamond cutting unit;

[0027] (3) The diamond cutting unit is fixed on the steel body of the saw blade by brazing to make a diamond saw blade.

[0028] The holding force coefficient of the diamond cutting unit matrix obtained in Example 1 to diamond was 0.538, and the impact strength of diamond was 0.889.

Embodiment 2

[0030] (1) Mixing 40-50 mesh synthetic diamond with a metal binder in a volume ratio of 1:4 to obtain a mixed powder, the metal binder includes Fe70Cu30 pre-alloyed powder 89.2%, Ni50Cr50 pre-alloyed powder 10.0%, Pr 0.8% (mass fraction );

[0031] (2) after the mixed powder is loaded into the graphite mold, hot-press sintering is performed, the sintering temperature is 1000 ° C, the sintering pressure is 15 MPa, and the temperature is kept for 5 minutes to obtain a diamond cutting unit;

[0032] (3) The diamond cutting unit is fixed on the steel body of the drill bit by welding to make a diamond drill bit.

[0033] The holding force coefficient of the cutter matrix obtained in Example 2 to diamond was 0.539, and the impact strength of diamond was 0.875.

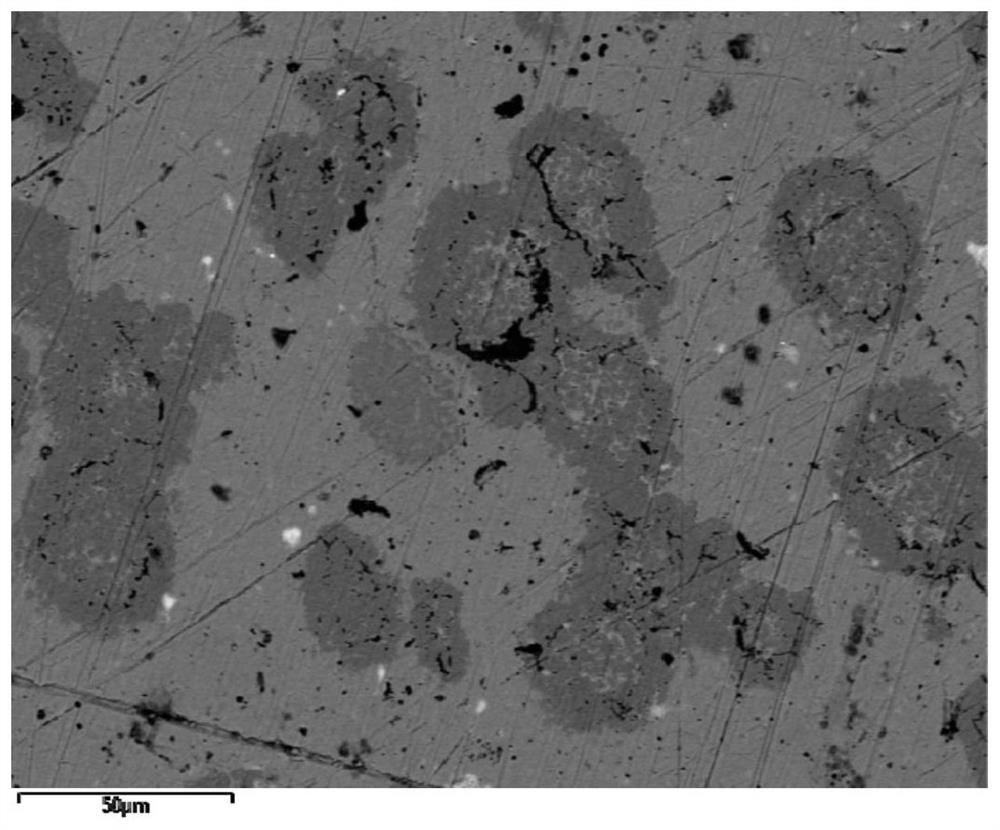

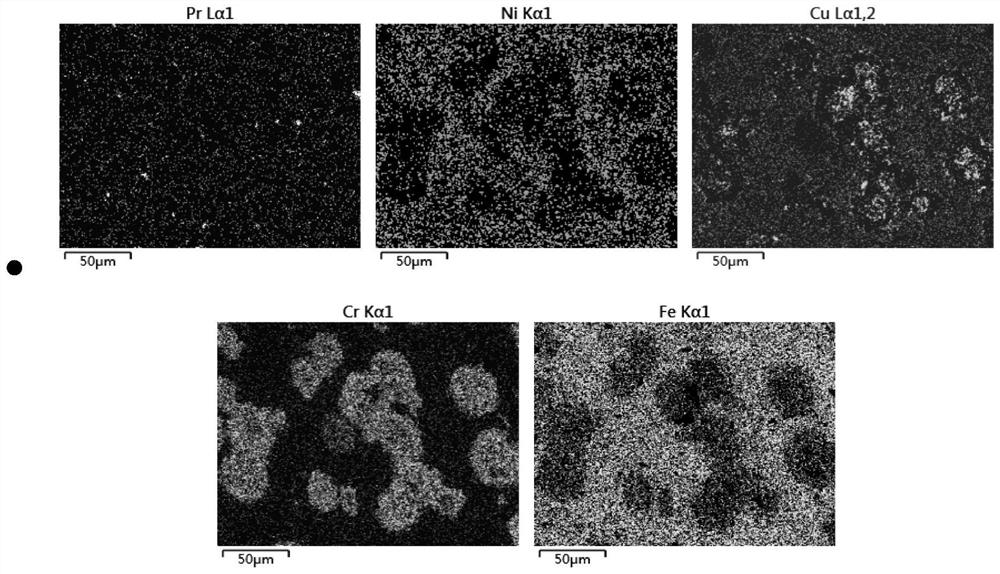

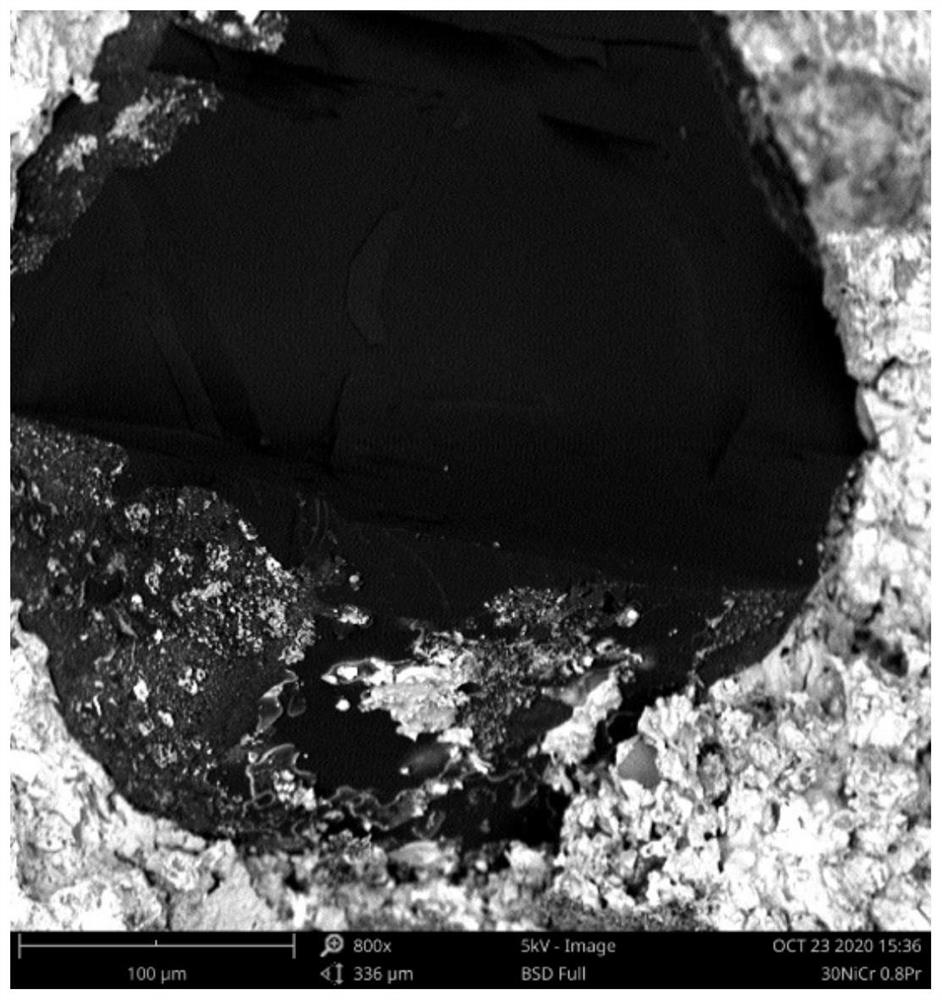

[0034] like figure 1 and figure 2 , it can be seen from the energy spectrum of the surface of the cutting unit carcass that Pr can promote the formation of solid solution of Cu and Cr, and improve the flexural strength o...

Embodiment 3

[0036] (1) Mix the 50-60 mesh synthetic diamond with a metal binder in a volume ratio of 3:10 to obtain a mixed powder, the metal binder includes Fe70Cu30 pre-alloyed powder 84.0%, Ni50Cr50 pre-alloyed powder 15.0%, Pr 1.0% (mass fraction );

[0037] (2) after the mixed powder is loaded into the graphite mold, hot-press sintering is performed, the sintering temperature is 1100 ° C, the sintering pressure is 18 MPa, and the temperature is kept for 6 minutes to obtain a diamond cutting unit;

[0038] (3) The diamond cutting unit is directly hot-pressed and sintered on the steel body of the drill to make a diamond drill.

[0039] The holding force coefficient of the cutter matrix obtained in Example 3 to diamond was 0.577, and the impact strength of diamond was 0.867.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com