Signal injection system for hardware-in-the-loop testing

A technology for injecting systems and signals, applied in the direction of test/monitoring control systems, general control systems, control/regulation systems, etc., can solve the problems of failing to achieve injection testing, difficult to change CAN message fault injection, and unclear logic of signal faults, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary and are only used to explain the present invention, but not to be construed as a limitation of the present invention.

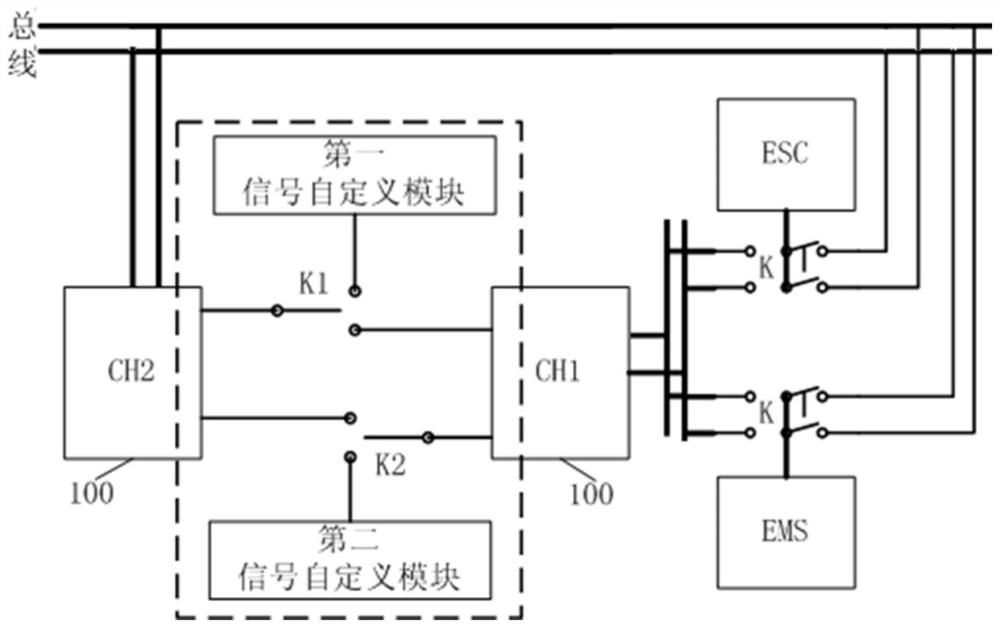

[0025] The present invention proposes an embodiment of a signal injection system for hardware-in-the-loop testing, specifically, such as figure 1 As shown, it may include: a bus board 100 and several double-pole double-throw switches K corresponding to the number of real controller nodes.

[0026] Specifically, the first channel CH1 of the bus board 100 is respectively connected to the first static terminal (or called the fixed terminal, static contact terminal, etc.) of each of the double-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com