Polyurethane soft foam

A soft foam and polyurethane technology, applied in the field of preparing polyurethane soft foam, can solve the problems of high boiling point of toluenediamine, non-volatile, human body harm and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The method for preparing flexible polyurethane foam of the present invention is to make the polyurethane reaction system comprising the following components to obtain the flexible polyurethane foam:

[0054] Component A, consisting of:

[0055] A1) toluene diisocyanate, its content is 15-80pbw, preferably 30-65pbw, based on 100pbw of component B;

[0056] A2) at least one aliphatic isocyanate, the content of which is 1-13pbw, preferably 1-12pbw, more preferably 1-8pbw, especially preferably 4-7pbw, based on 100pbw of component B;

[0057] Component B, one or more polyether polyols, comprising:

[0058] B1) Based on the total weight of B1, the ethylene oxide unit content is 0-30wt%, preferably 5-20wt%, the average functionality is 2-4, and the hydroxyl value is 80-180mgKOH / g (test method GB / T 12008.3-2009 ) polyether polyol, the content of which is 30-100pbw, preferably 80-100pbw, based on 100pbw of component B;

[0059] Component C, at least one blowing agent; and

...

Embodiment

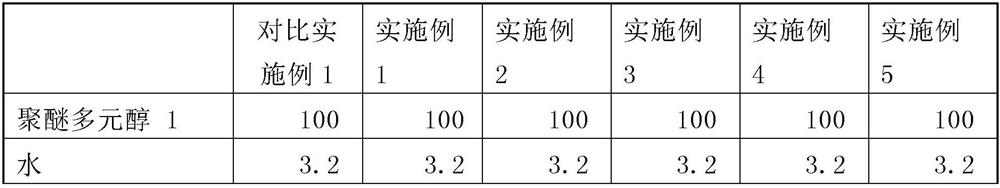

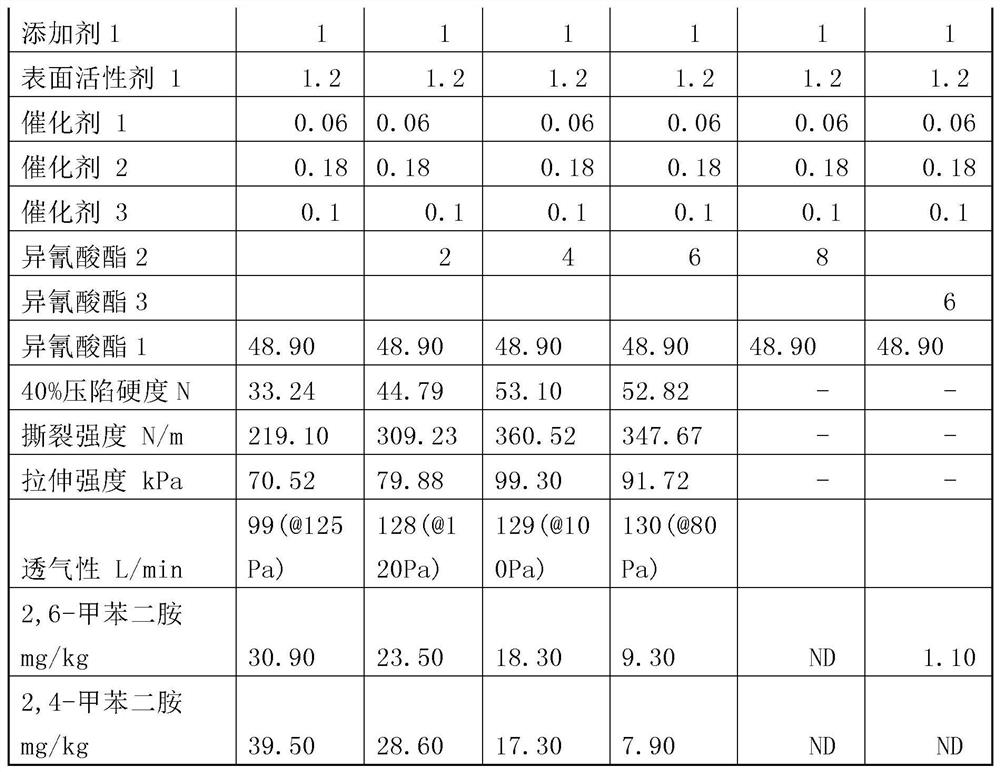

[0128] The various test methods of the embodiment are described as follows:

[0129] Indentation hardness refers to the force required to achieve a certain deformation using a standard sample under specified conditions and instrument test procedures, measured by GB / T 10807-2006;

[0130] Tensile strength refers to the maximum tensile stress suffered by the sample during the stretching process, measured by GB / T 6344-2008;

[0131] Tear strength refers to the force required to tear a thin sample, measured by GB / T 10808-2006;

[0132] Air permeability refers to the ability of air to pass through the foam, the test method ASTM D3574-G, and the test condition is a pressure difference of 125Pa. Comparative example 1 records the air permeability according to ASTM D3574--2005 as shown in table 1; in embodiment 1 In -3, the data cannot be measured when the pressure difference is 125Pa using the aforementioned test method, indicating that the air permeability is very good; if the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com