Lifting type printing and drying mechanism for corrugated boards

A technology for printing drying and corrugated cardboard, which is applied in printing, printing devices, and dispersed particle filtration, etc. It can solve the problems of inconvenient adjustment of the printing nozzle and the drying structure of corrugated cardboard, affect the printing and drying effect, and achieve ink stimulation. Eliminate irritating odors, correct the direction of materials, and achieve the effect of lubrication and anti-wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

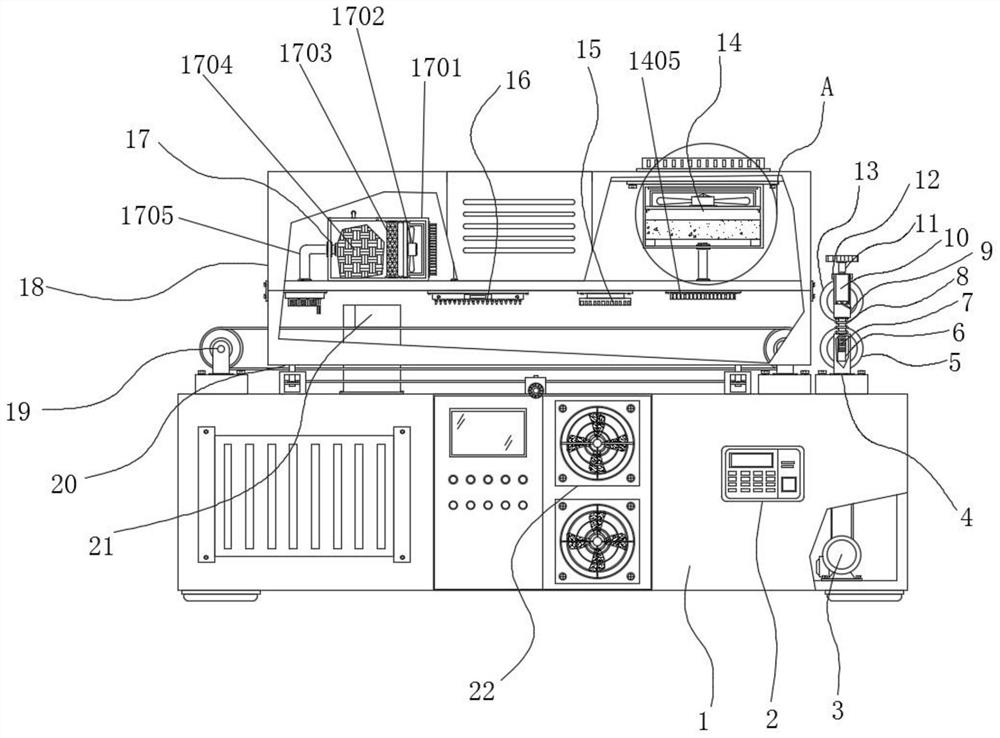

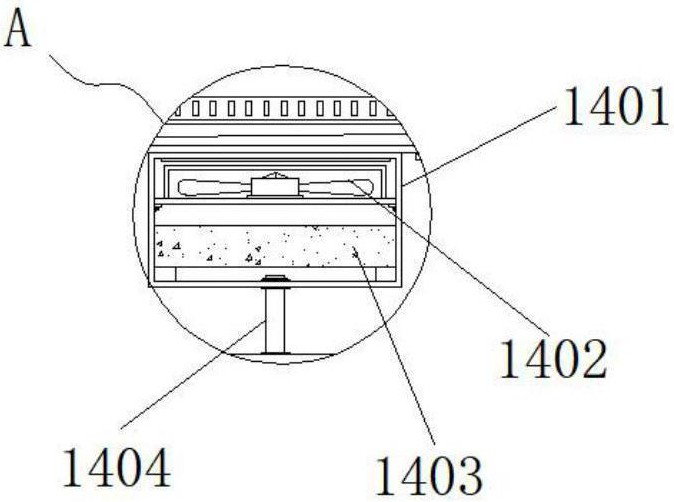

[0041] Example 1: as figure 1 , Figure 7 , Figure 8 A lifting type printing and drying mechanism for corrugated cardboard includes a first box body 1, a controller 2 is fixedly connected to one side of the front end of the first box body 1, and a conveyor belt 19 is arranged at the top of the first box body 1, The front and rear ends of the top end of the first box body 1 are fixedly connected with a support plate 20 , a lift chute 201 is arranged on the support plate 20 , a horizontal plate 202 is fixed in the lift chute 201 , and a support swivel 203 is rotatably installed on the horizontal plate 202 , a transmission gear 204 is fixed on the support swivel 203, a compression spring 205 is arranged between the upper end of the transmission gear 204 and the upper end of the lifting chute 201, the inner ring side of the transmission gear 204 is connected with a lifting screw 206 through a thread, and the upper end of the lifting screw 206 is lifted by a lifting screw The up...

Embodiment 2

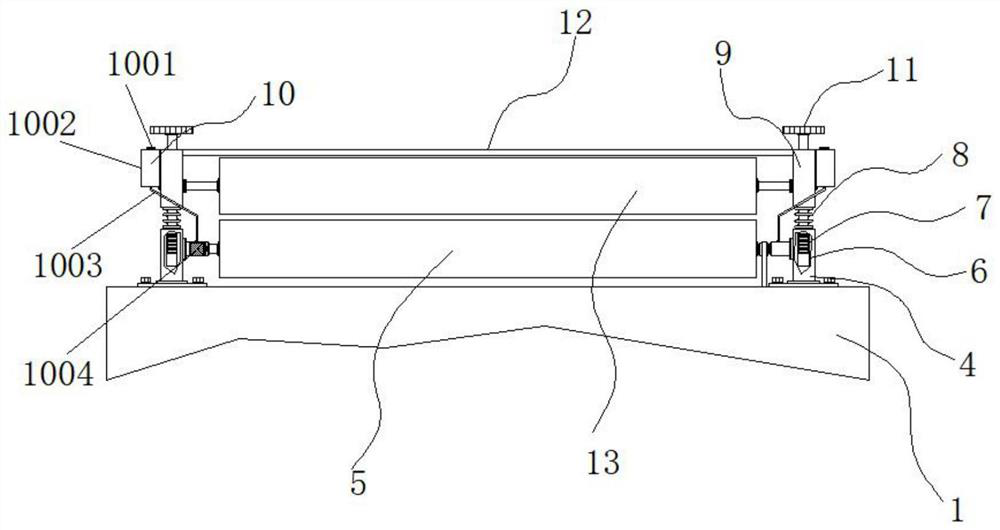

[0043] Example 2: On the basis of Example 1, please refer to Figure 1-6 , a drive motor 3 is fixedly connected to one side of the inner bottom end of the first box body 1, the specific model of the drive motor 3 can be Y90S-2, and one side of the top end of the first box body 1 is fixedly connected to a support seat 4, the support seat 4 A driving roller 5 is movably connected therebetween through a fixed bushing, a fixed block 9 is arranged above the support base 4, a pressing roller 13 is movably connected between the fixed blocks 9, a connecting rod 12 is fixedly connected between the fixed blocks 9, and the support base The top of 4 is provided with a compression tightness adjustment structure;

[0044] see Figure 1-6 , the compression tightness adjustment structure includes a threaded cavity 6, the threaded cavity 6 is arranged inside the support seat 4, the top end of the support seat 4 and the bottom end of the fixing block 9 are fixedly connected with a support spri...

Embodiment 3

[0047] Embodiment 3: The front end of the fixed block 9 is provided with a lubricating structure 10. The lubricating structure 10 is composed of a sealing cover 1001, an oil storage box 1002, a conduit 1003, an oiling ring 1004 and a foam ring 1005. The oil storage box 1002 is fixedly connected to the fixed The front end of the block 9 and the top of the oil storage box 1002 are fixedly connected with a sealing cover 1001. The oiling ring 1004 is arranged inside the fixed shaft sleeve on one side of the support seat 4. The top of the oiling ring 1004 and the bottom end of the oil storage box 1002 are connected A conduit 1003 is fixedly connected between them, and a foam ring 1005 is arranged at the top of the oiling ring 1004;

[0048] Small holes are evenly arranged inside the foam ring 1005, and the inside of the conduit 1003 and the oiling ring 1004 are communicated;

[0049] Specifically, as figure 1 , figure 2 and Image 6 As shown, the sealing cover 1001 is opened, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com