Magneto-rheological and shape-memory alloy friction composite brake by electromagnetic extrusion

A technology of memory alloy and composite braking, which is applied in the direction of drum brakes, brake types, liquid resistance brakes, etc., can solve the problems of high temperature influence, poor braking effect, and poor stability, so as to reduce energy waste and enhance braking dynamic performance and reduce the effect of performance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

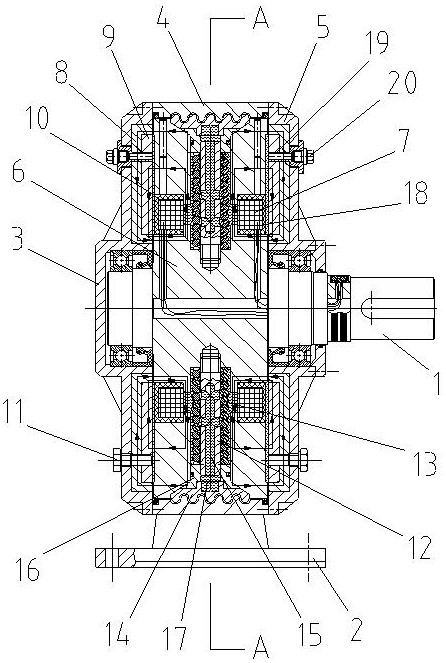

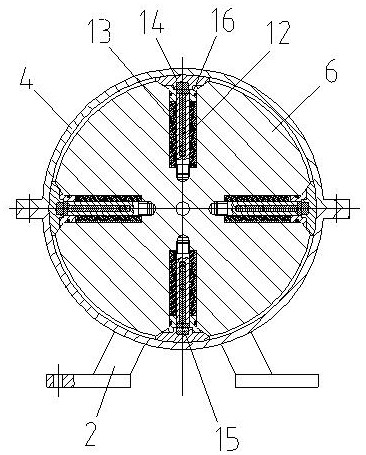

[0024] Example: see figure 1 , figure 2 , an electromagnetic extruded magneto-rheological and shape memory alloy friction composite brake, comprising a brake shaft 1, a brake housing and a brake base 2. The brake housing includes a left casing 3 , an outer cylinder 4 and a right casing 5 connected in sequence, and the brake base 2 is fixedly connected to the outer cylinder 4 . The left end of the brake shaft 1 passes through the right housing 5 and then extends into the brake housing, and is rotatably connected with the left housing 3 and the right housing 5 through bearings, wherein the bearings only have oil-sealed bearings, which are sealed The lip is in close contact with the brake disc 6; thereby the automatic casing can be effectively sealed. A brake disc 6 is also provided in the brake housing, and the brake disc 6 is sleeved on the brake shaft 1, and is solidly integrated with the brake shaft 1, and the brake disc 6 is connected with the left housing 3, the outer T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com