Light blind bolt

A blind, bolt technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of cumbersome process, high production and processing cost, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

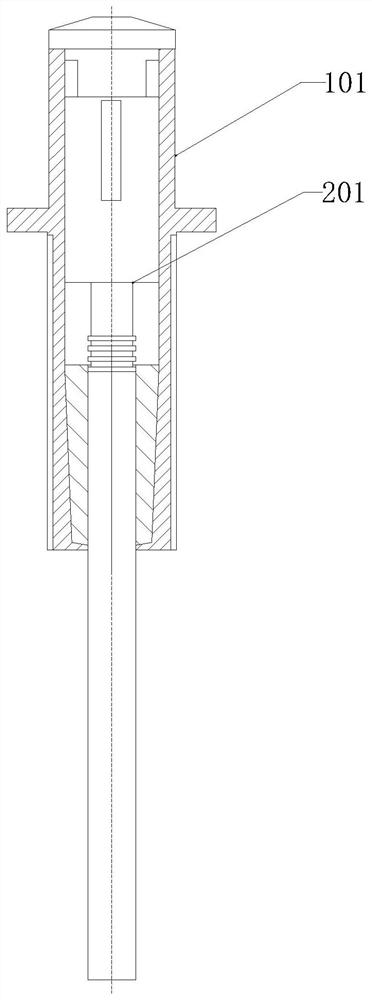

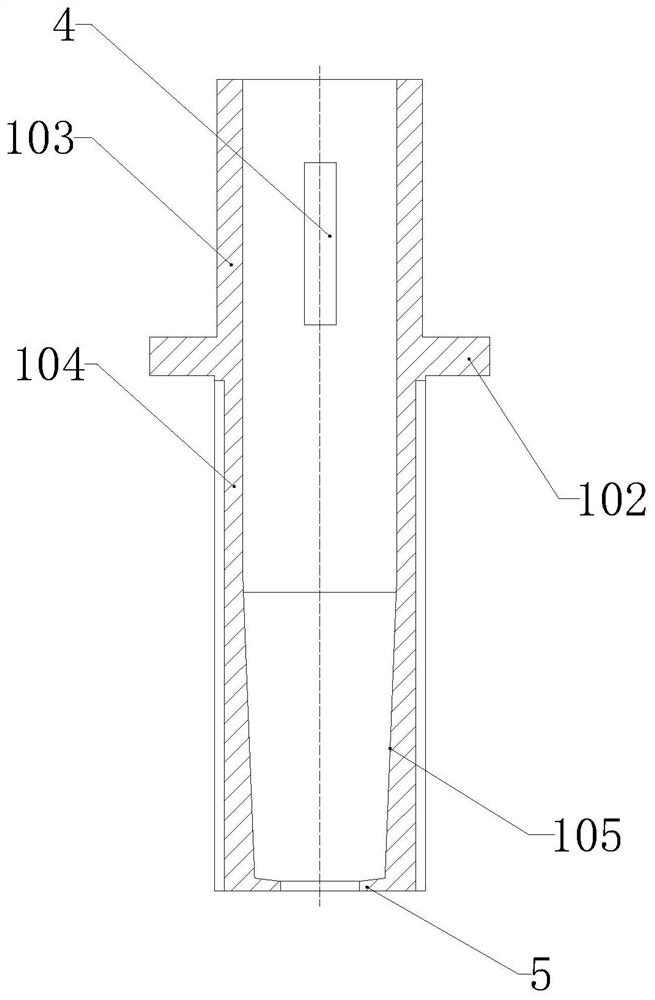

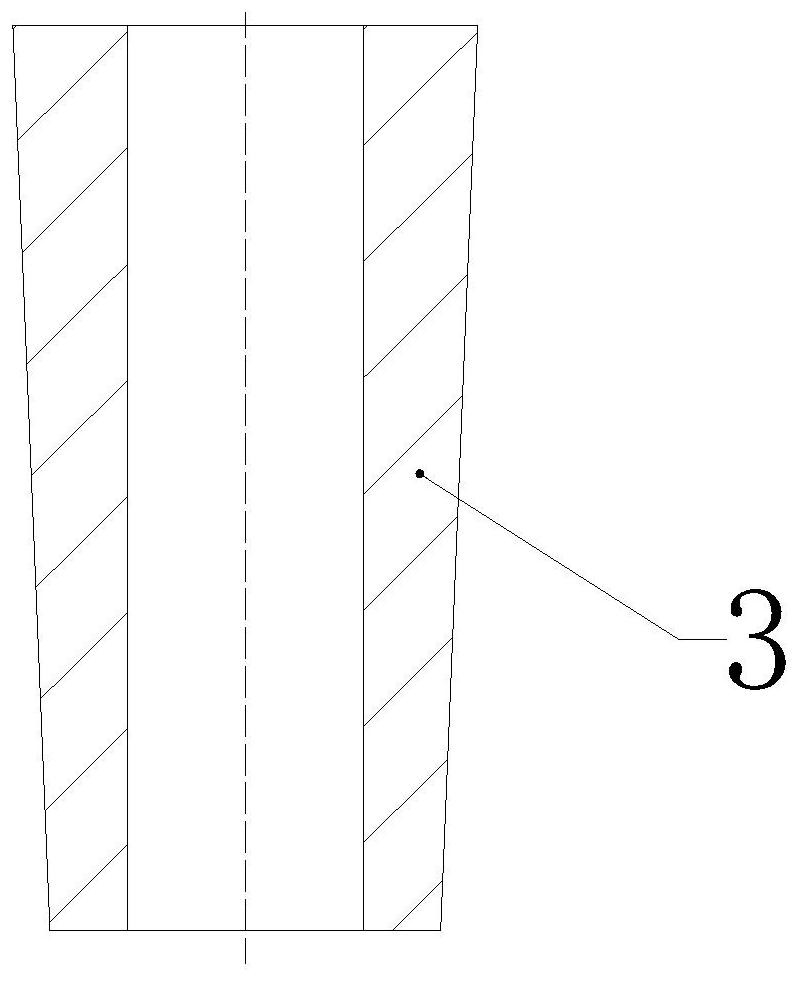

[0027] see Figure 1 to Figure 7 , a light-duty blind bolt according to a preferred embodiment of the present invention includes a nail body 1 and a nail core 2, the nail body includes a nail body tube 101, and a lock fixed to the nail body tube is provided on the outer surface of the nail body tube. Tightening platform 102, the part of the nail body tube positioned above the locking platform is the nail body tube deformation part 103, the part of the nail body tube positioned below the locking platform is the nail body tube locking part 104, and the bottom of the nail body tube inner hole is Locking hole 105, the locking hole is a tapered hole whose aperture gradually de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com