Pipe network dredging robot

A robot and pipe network technology, applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc., can solve the problems of inability to completely clean, low efficiency, low dredging efficiency, etc., to achieve strong ability to overcome obstacles and muddy ground, Improve the efficiency of dredging and improve the effect of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solution of the application, the application will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the application. .

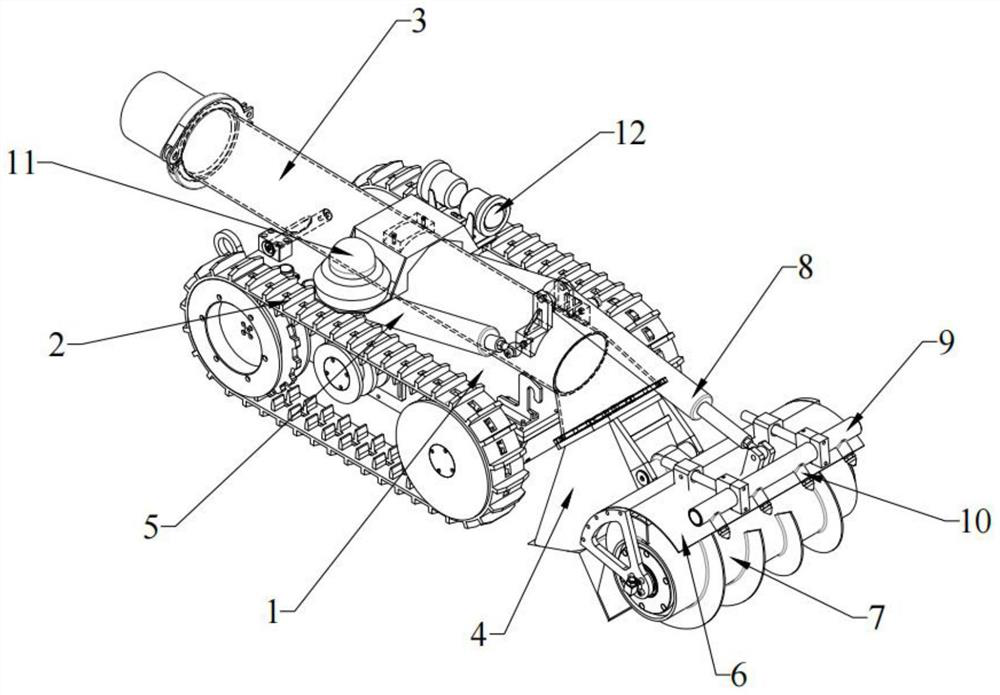

[0021] Please refer to figure 1 , this embodiment provides a pipe network dredging robot, including a base 1, a walking assembly 2, a suction assembly and a crushing assembly.

[0022] The walking assembly 2 is installed on the lower part of the base 1, and is used to drive the base 1 to walk in the pipeline; the walking assembly 2 includes walking crawlers arranged symmetrically on the left and right sides of the base 1; The driving wheel and the driven wheel meshed with it are arranged in the walking track; the driving wheel and the driven wheel are cylindrical structures with the same tooth shape on the outer ring; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com