Efficient synergistic resource utilization method for livestock and poultry manure and silage straw

A resourceful, livestock and poultry manure technology, applied in the direction of biochemical equipment and methods, methods based on microorganisms, biochemical instruments, etc., can solve the problems of low gas production rate, difficult treatment and disposal, etc., to increase gas production and increase residence time , the effect of stabilizing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

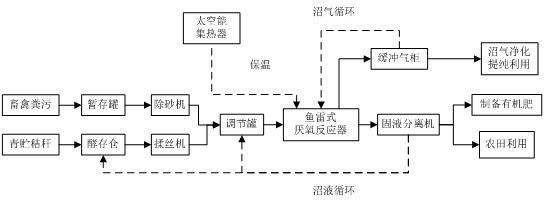

[0046] Mix pig manure and straw at a ratio of 5:1 and carry out anaerobic fermentation. The silage straw is crushed to 5mm, and 3% of the compound cellulose-decomposing active bacteria are added to the returning biogas slurry and evenly sprayed on the surface of the silage straw for fermentation. After 30 days, the desanded pig manure was mixed evenly with the crushed silage straw particles, and the solid content rate was adjusted to 10%.

[0047] The mixed material enters the anaerobic fermentation tank 7, the temperature is maintained at 38 ° C, the pH value is 6.7-7.5, and the residence time is 35 days. The rotary jet agitator 16 and the blower 9 are operated 8 times a day. After anaerobic fermentation, "three Swamp" products.

[0048] Part of the biogas is used for gas-liquid stirring and recycling, and part of it is purified and purified to prepare vehicle-mounted compressed natural gas; biogas residues are aerobically fermented to prepare high-quality organic fertilizers...

Embodiment 2

[0050] Mix chicken manure and straw at a ratio of 7:3 and carry out anaerobic fermentation. The silage straw is crushed to 6 mm, and 4% of the compound cellulose-decomposing active bacteria are added to the backflowing biogas slurry and evenly sprayed on the surface of the silage straw for fermentation. After 40 days, the pig manure after desanding and the crushed silage straw particles are mixed evenly, and the solid content rate is adjusted to 15%.

[0051] The mixed material enters the anaerobic fermentation tank 7, the temperature is maintained at 42 ° C, the pH value is 7.2-7.5, and the residence time is 40 days. The rotary jet agitator 16 and the blower 9 are operated 8 times a day. After anaerobic fermentation, "three Swamp" products.

[0052] Part of the biogas is recycled by gas-liquid mixing, and part of the biogas enters the boiler and can be used for heating for surrounding residents; after aerobic fermentation of biogas residues, bulk organic fertilizers are prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com