A short-distance displacement lifting device for chemical production

A lifting device, chemical production technology, applied in the direction of lifting device, lifting frame, packaging, etc., can solve the problems of cumbersome operation, inability to adjust the angle, and inability to arrange personnel, etc., to achieve fine adjustment operation, flexible and convenient use form, and easy maintenance The effect of dispatch operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

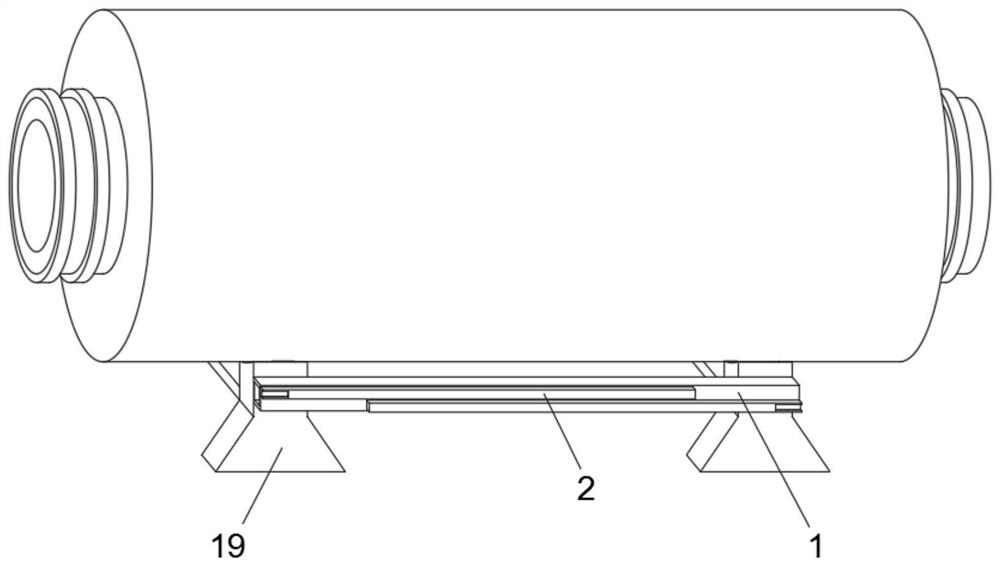

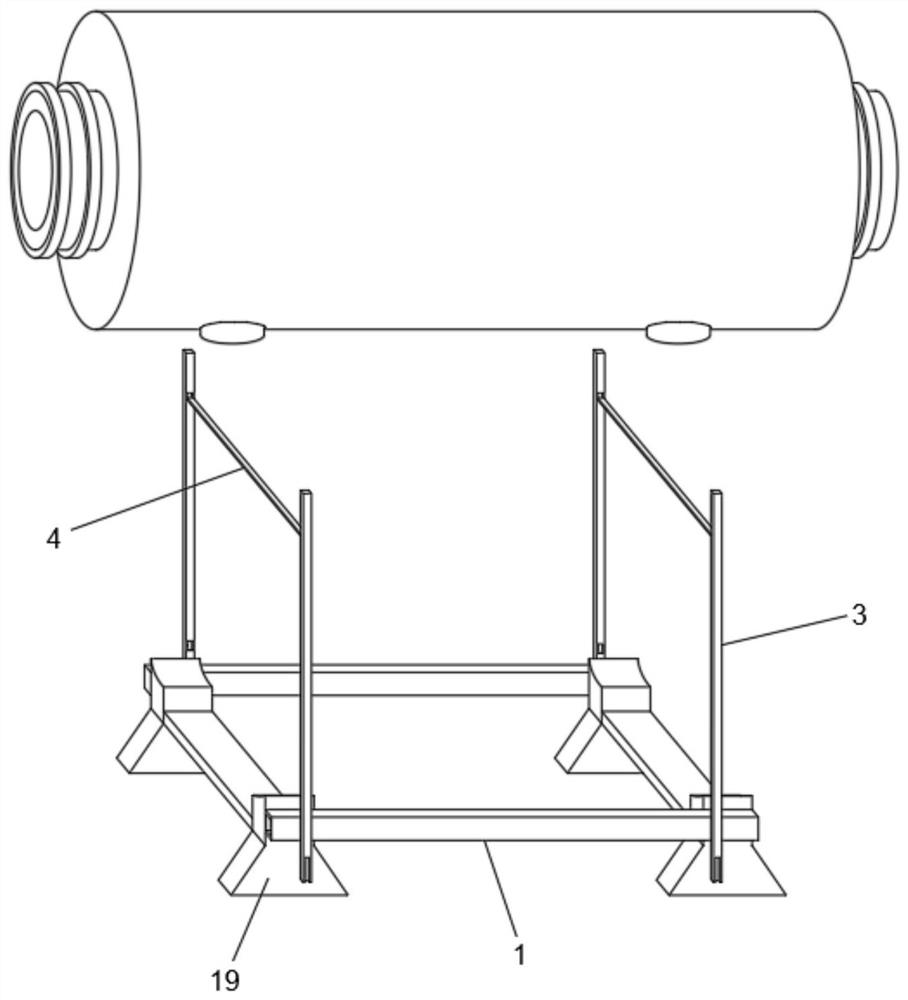

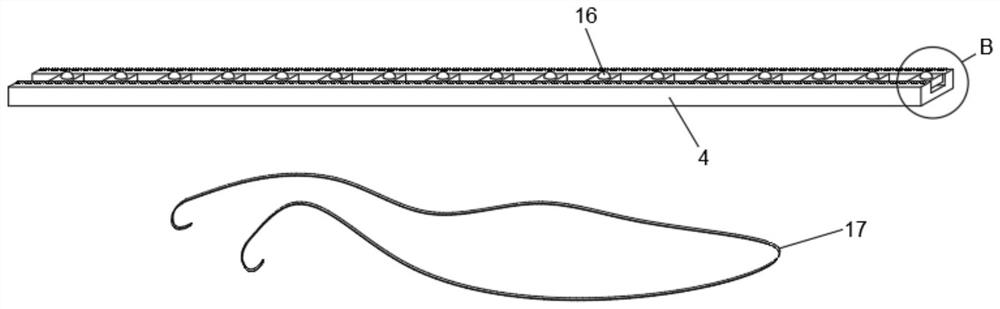

[0030] Such as Figure 1-9 As shown, a short-distance displacement lifting device for chemical production mainly relies on two hollow columns 1 as the base for installation and support, and the hollow columns 1 are mainly installed on the base 19, which can be such as triangular steel or iron Mass base, the hollow part of the hollow column 1 is only distributed at the ends of both ends, the center is used as a solid to strengthen the measurement of rigid force, and there are many holes on the inner wall of the hollow part of the hollow column 1 for fixed connection , the hollow column 1 can be fixed on the base by using bolts through holes, or it can be disassembled and placed on another component for repeated use after the chemical tank is hoisted, or it can be installed on a mobile device for short-distance movement , which further enriches the functionality of the component.

[0031] The hollow column 1 is rotatably connected with a plurality of load-bearing rods 2. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com