A flywheel mechanism for belt connection unlocking device

An unlocking device and flywheel technology, which is applied in the docking device of aerospace vehicles, transportation and packaging, and aerospace vehicles, etc., can solve the problems of large impact force loads, etc., to reduce impact, reduce locking force, and extend strap unlocking the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

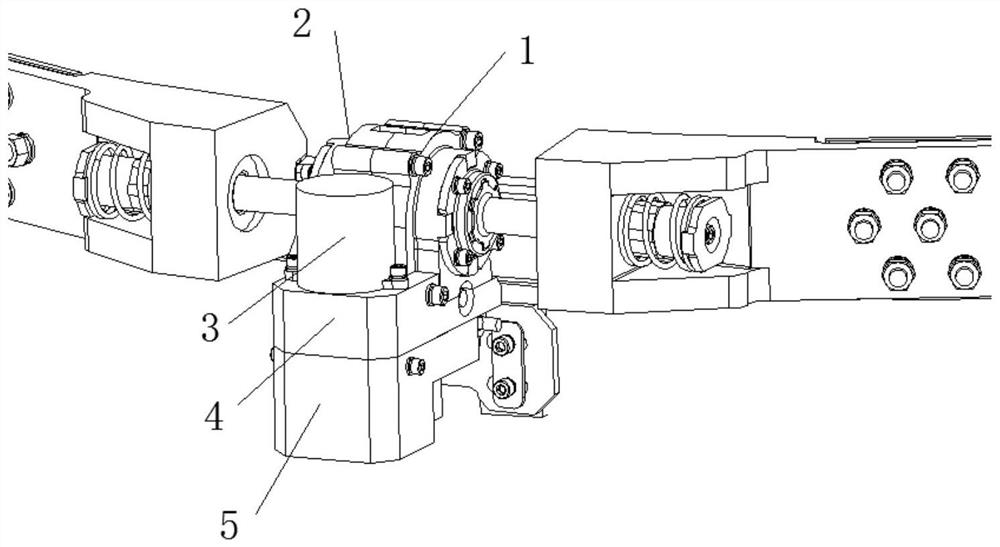

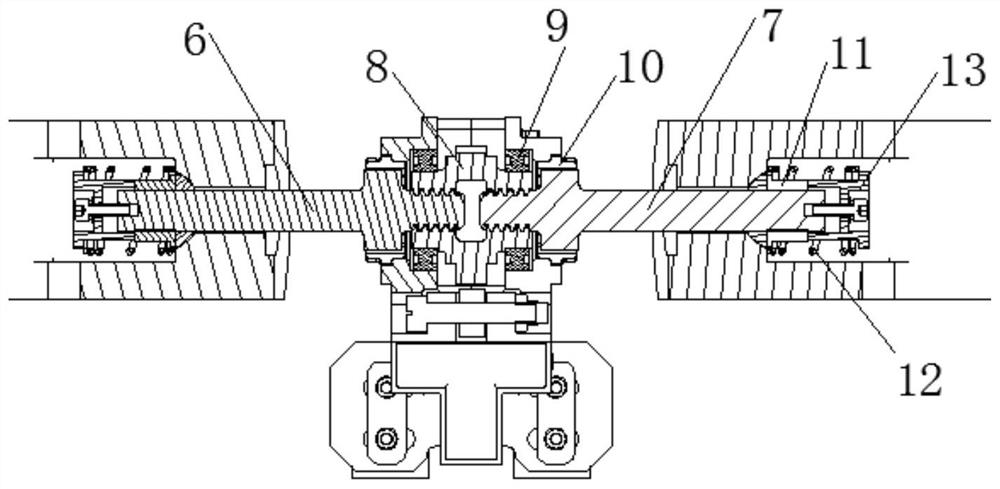

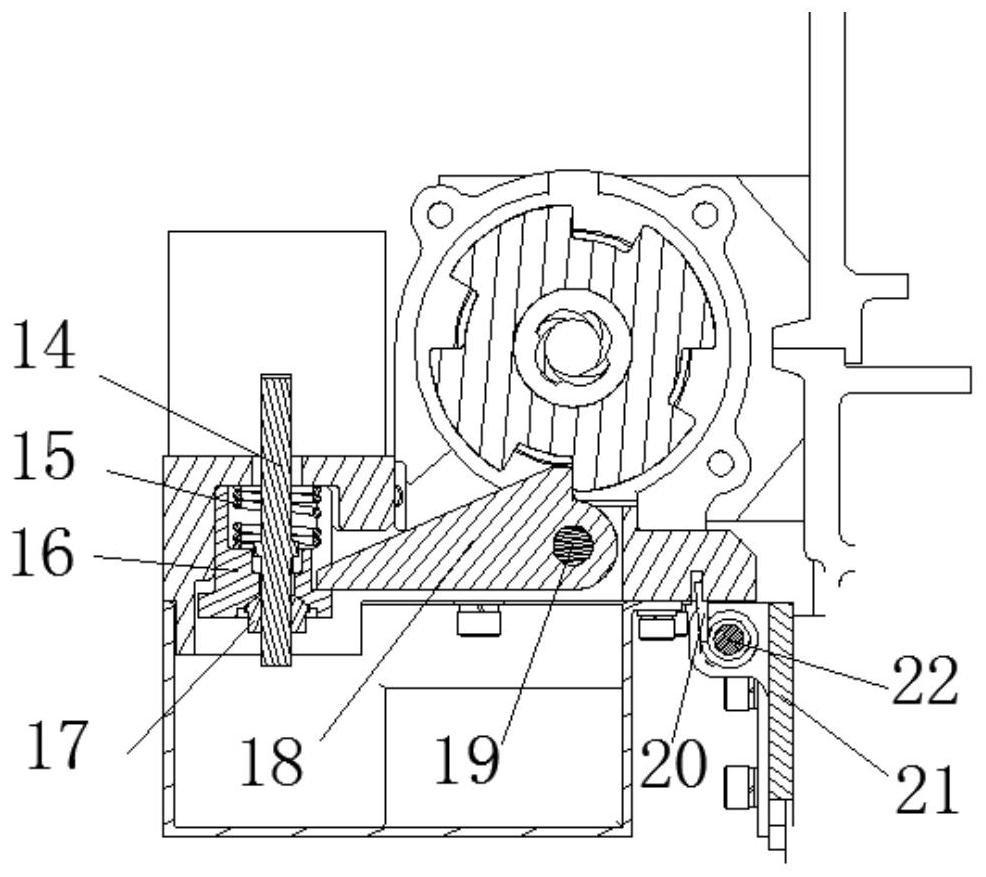

[0029] figure 1 is the structural schematic diagram of the flywheel mechanism used for the strap connection unlocking device according to the embodiment of the present invention, figure 2 It is the structural schematic diagram of the front section of the flywheel mechanism used for the strap connection and unlocking device according to the embodiment of the present invention, image 3 It is a structural schematic diagram of a side view section of a flywheel mechanism used for a strap connection and unlocking device according to an embodiment of the present invention. see Figure 1 to Figure 3 , the flywheel mechanism of the present invention for the strap connection and unlocking device includes a left casing 1, a right casing 2, a separation nut 3, a platform support 4, a collection box 5, a left-handed screw 6, a right-handed screw 7, a flywheel 8, Bearing 9, end cap 10, loading nut 11, compression spring 12, spring end cap 13, double-ended screw 14, unlocking spring 15, ...

Embodiment approach 2

[0037] The difference between this embodiment and Embodiment 1 is that:

[0038] The pin is used to directly realize the constraint of the flywheel 8. When unlocking, the action of pulling the pin can realize the rotation and unlocking of the flywheel 8 without restraint. Except for this, other aspects of this embodiment are the same as those of the first embodiment. It is not repeated here.

[0039] Figure 4 It is a schematic diagram of the installation of the flywheel mechanism for the strap connection and unlocking device according to the embodiment of the present invention. like Figure 4 As shown, the flywheel mechanism of the present invention for the strap connection and unlocking device reduces the large pre-tightening force of the strap to a small locking force, and the flywheel rotates and unlocks to realize the slow release of the strap pre-tightening force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com