Manufacturing method of full-core reinforced composite template

A technology for enhancing composite and manufacturing methods, applied in the field of composite material manufacturing, can solve the problems of cumbersome production process, high cost, and the core layer is not reinforced, and achieves the effect of reducing the cost of template engineering, high turnover and convenient demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

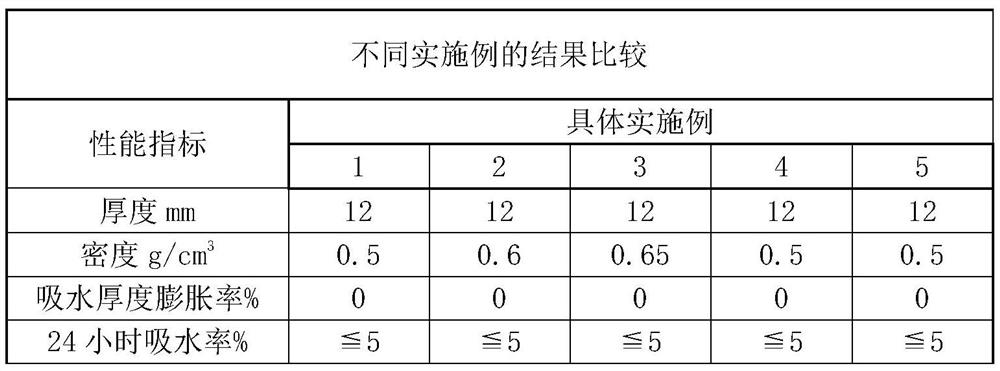

Examples

Embodiment 1

[0028] A method for manufacturing a full-core reinforced composite template, comprising the following steps:

[0029] Step 1: mixing materials;

[0030] Stir the formaldehyde-based resin, diluent, curing agent, release agent, and modifier, and after mixing thoroughly, add a foaming agent and mix for more than 15 minutes to obtain a mixture; among them, the preferred mass ratio of the formaldehyde-based resin is 6:3 The mixture of phenolic resin and benzoxazine resin, the diluent is preferably a mixture of alcohol and water with a mass ratio of 1:2, the curing agent is preferably a 60% aqueous solution of phthalic anhydride, and the mold release agent is preferably zinc stearate. The modifier is preferably polyvinyl alcohol, the foaming agent is preferably a mixture of AC, NC and microbeads with a mass ratio of 0.3:0.4:1, formaldehyde-based resin, diluent, curing agent, mold release agent, modifier, foaming agent The mass percentage of agent is: 40:37:1:4:15:3.

[0031] Step ...

Embodiment 2

[0041] A method for manufacturing a full-core reinforced composite template, comprising the following steps:

[0042] Step 1: mixing materials;

[0043] Stir the formaldehyde-based resin, diluent, curing agent, release agent, and modifier, and after mixing thoroughly, add a foaming agent and mix for more than 15 minutes to obtain a mixture; among them, the preferred mass ratio of the formaldehyde-based resin is 6:3 The mixture of phenolic resin and benzoxazine resin, the diluent is preferably a mixture of alcohol and water with a mass ratio of 1:2, the curing agent is preferably a 60% aqueous solution of phthalic anhydride, and the mold release agent is preferably zinc stearate. The modifier is preferably polyvinyl alcohol, the foaming agent is preferably a mixture of AC, NC and microbeads with a mass ratio of 0.3:0.4:1, formaldehyde-based resin, diluent, curing agent, mold release agent, modifier, foaming agent The mass ratio of the agent is: 40:22:1:4:30:3.

[0044] Step 2...

Embodiment 3

[0054] A method for manufacturing a full-core reinforced composite template, comprising the following steps:

[0055] Step 1: mixing materials;

[0056] Stir the formaldehyde-based resin, diluent, curing agent, release agent, and modifier, and after mixing thoroughly, add a foaming agent and mix for more than 15 minutes to obtain a mixture; among them, the preferred mass ratio of the formaldehyde-based resin is 6:3 The mixture of phenolic resin and benzoxazine resin, the diluent is preferably a mixture of alcohol and water with a mass ratio of 1:2, the curing agent is preferably a 60% aqueous solution of phthalic anhydride, and the mold release agent is preferably zinc stearate. The modifier is preferably polyvinyl alcohol, the foaming agent is preferably a mixture of AC, NC and microbeads with a mass ratio of 0.3:0.4:1, formaldehyde-based resin, diluent, curing agent, mold release agent, modifier, foaming agent The mass ratio of the agent is: 40:17:1:4:35:3.

[0057] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com