Variable open winding motor topology driving circuit and control method thereof

A technology of a driving circuit and a control method, which is applied in the field of variable open-winding motor topology driving circuit and its control, can solve the problems of large switching loss and low utilization rate of DC voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

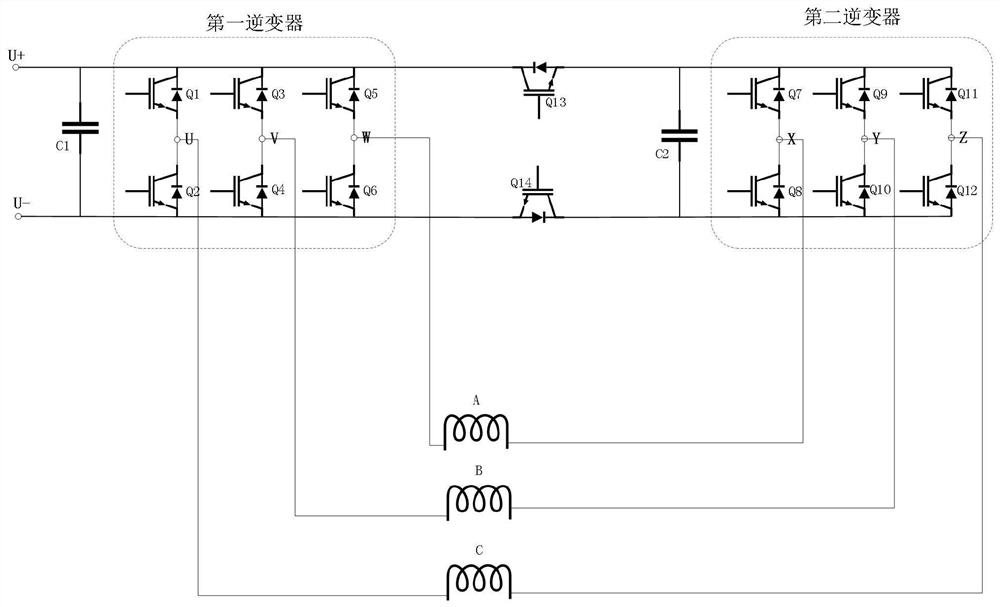

[0018] as attached figure 1 As shown, it is a schematic diagram of a variable open-winding motor driving topology of a variable open-winding motor topology driving circuit of this embodiment.

[0019] This embodiment provides a variable open-winding motor topology drive circuit, including a first inverter and a second inverter, and a switch is provided at the DC bus between the first inverter and the second inverter tube, by controlling the on and off of the switch tube, the function switching between the three-phase inverter drive control circuit and the open-winding motor drive circuit of the common DC bus is realized.

[0020] The first inverter includes three sets of switching tubes Q1, Q2, Q3, Q4, Q5, and Q6 connected in parallel, and the second inverter includes three sets of switching tubes Q7, Q8, Q9, Q10, and Q11 connected in parallel. , Q12, switch tubes Q13 and Q14 are set at the DC bus between the first inverter and the second inverter, one side of the first inver...

Embodiment 2

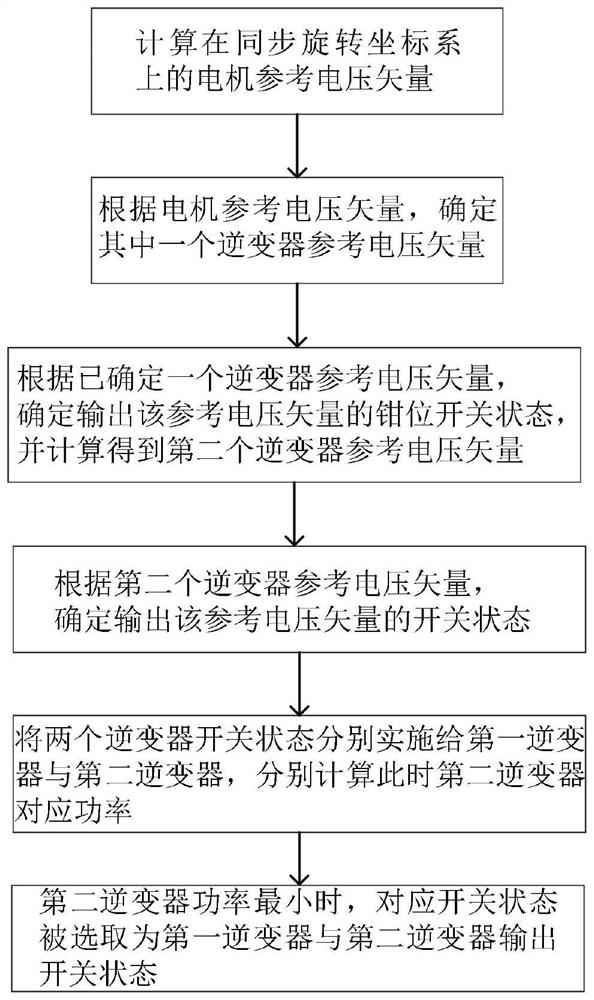

[0030] This embodiment provides a control method for a variable open-winding motor topology drive circuit, and the specific implementation is as follows:

[0031] The control process of the variable open-winding motor topology drive circuit in this embodiment is mainly divided into the following working conditions:

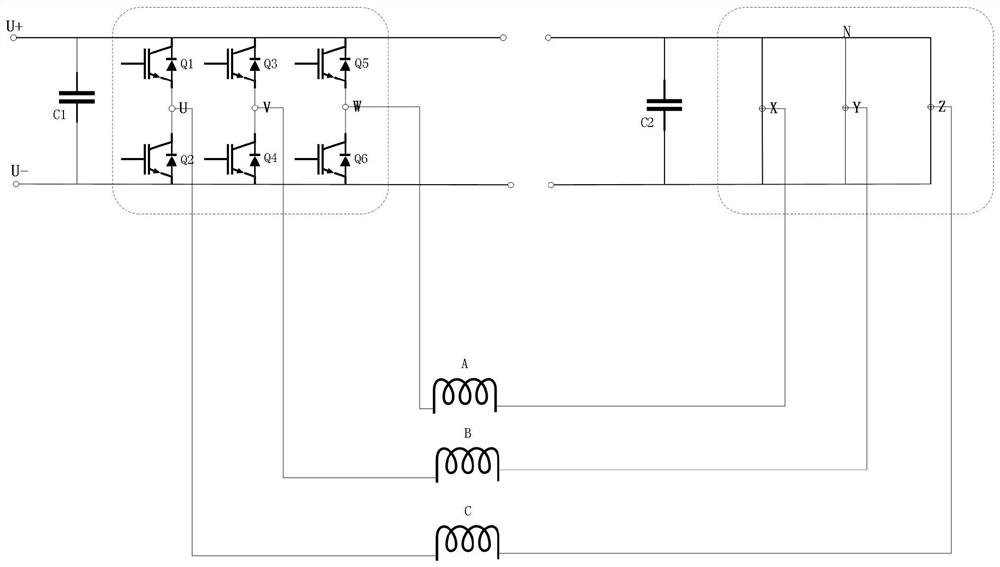

[0032] 1. As attached image 3 As shown, when the motor speed is lower than 30% of the rated speed, the back electromotive force of the permanent magnet synchronous motor is low. Compared with the common bus open-winding drive structure, the traditional three-phase inverter structure can be satisfied by using fewer switching tubes and switching times. Motor operating conditions. At this time, the DC bus of the first inverter is connected to the DC source, the two switching tubes Q13 and Q14 at the common DC bus are disconnected, and the switching tubes of the second inverter are all turned on. At this time, the bridge arms of the first inverter form a traditiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com