Method for predicting creep life of nickel-based single crystal superalloy containing Re and Ru

A creep life, high temperature alloy technology, applied in neural learning methods, biological neural network models, instruments, etc., can solve the problems of small amount of data, complex mechanism, limited amount of data, etc., and achieve the effect of improving prediction accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

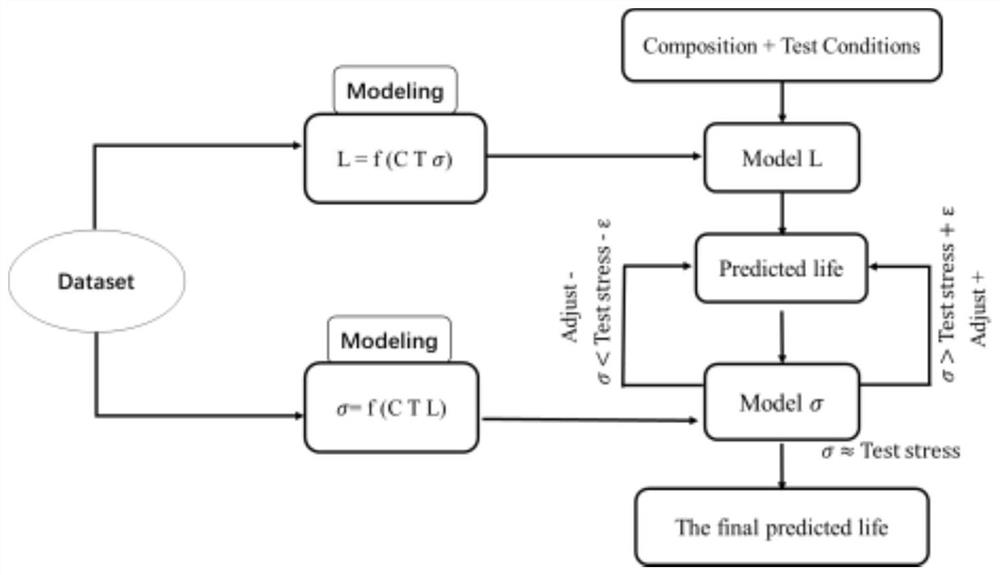

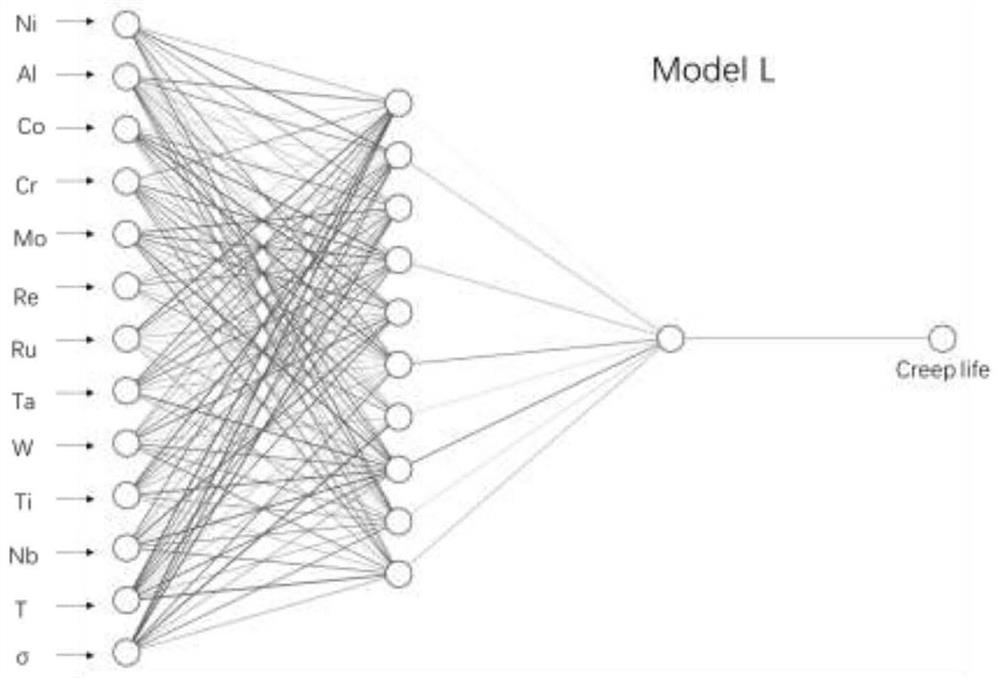

Method used

Image

Examples

Embodiment Construction

[0025] The following examples will further illustrate the present invention, so that those skilled in the art can better understand the advantages and features of the present invention.

[0026] First, 5 nickel-based single crystal superalloy data that are not in the database used for modeling are selected. The alloys involve 5 different generations, namely RenéN5 (2nd generation), CMSX-10 (3rd generation), MX-4 ( 4th generation), TMS-173 (5th generation), TMS-238 (6th generation), alloy composition and creep conditions are shown in Table 1.

[0027] Table 1

[0028]

[0029] Note: T—creep test temperature, σ—creep test stress.

[0030] Input the composition, creep temperature and creep stress of the five alloys into the model Model L according to the data in Table 1, and obtain the predicted initial creep life respectively. The initial predicted life is 96h, 382h, 492h, 1277h, 616h, The composition, creep temperature and initial creep life were input into the model Model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com