Modeling of an igct water-cooled radiator and its junction temperature calculation method

A water-cooled radiator and calculation method technology, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of inaccurate prediction results in practical applications, failure to consider the influence of temperature distribution, and prediction of junction temperature. The effect of easy software programming, accurate calculation and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] A method for modeling an IGCT water-cooled radiator and calculating its junction temperature comprises the following steps:

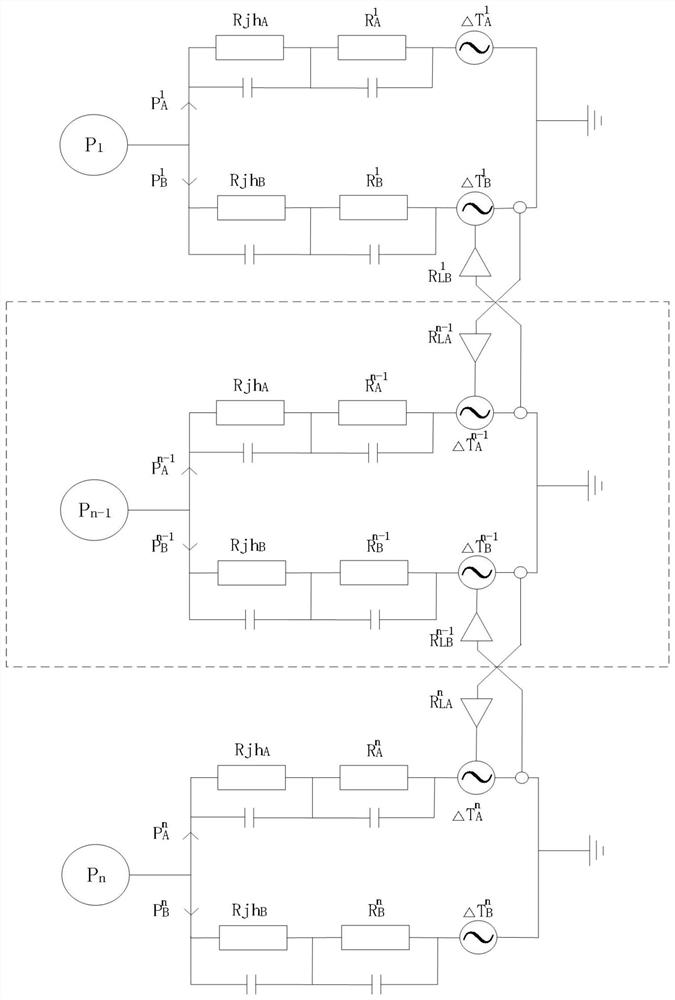

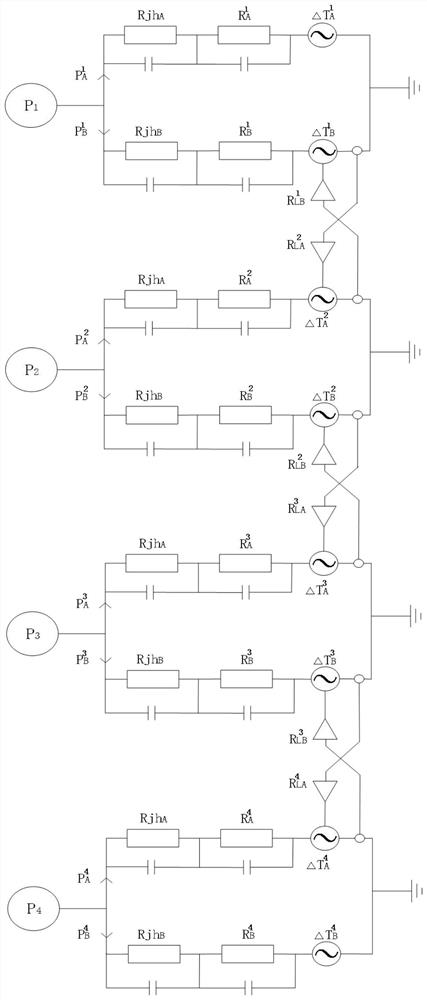

[0043] Step 1. Establish a radiator temperature rise thermal resistance model, and use the temperature rise thermal resistance model to calculate radiator thermal resistance parameters of a single IGCT water-cooled radiator.

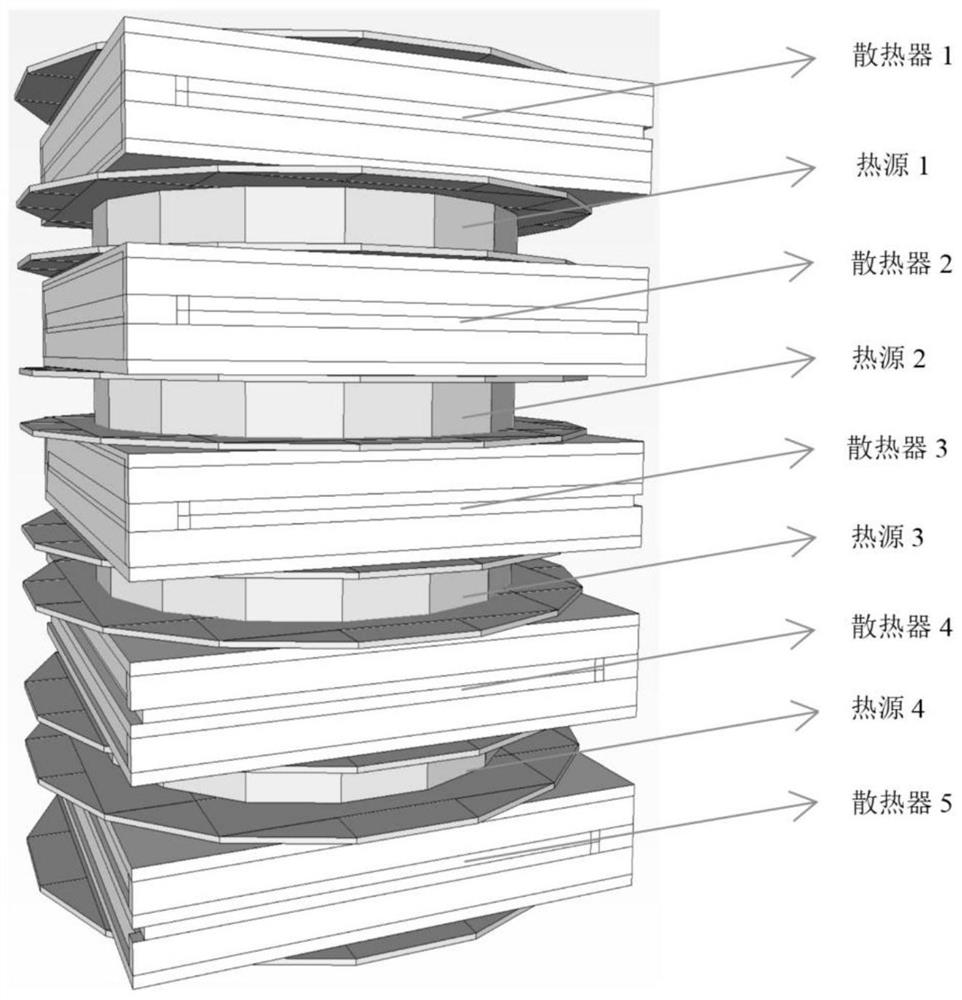

[0044] The IGCT water-cooled radiator is designed for double-sided heat dissipation. The front and back sides of the interior are made of round planes of stainless steel and cast aluminum alloy. The cooling water first enters one stainless steel water pipe, and then flows from the center to the other stainless steel water pipe. Therefore, the internal water circuit is serially radiated. The heat dissipation performance of the upper and lower sides of the device is different. For example, in practical appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com