Speed changer and harvester

A transmission and clutch technology, applied to harvesters, clutches, mechanical equipment, etc., can solve problems such as low operating efficiency and high failure rate, and achieve the effects of reducing failure rate, improving adaptability, and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

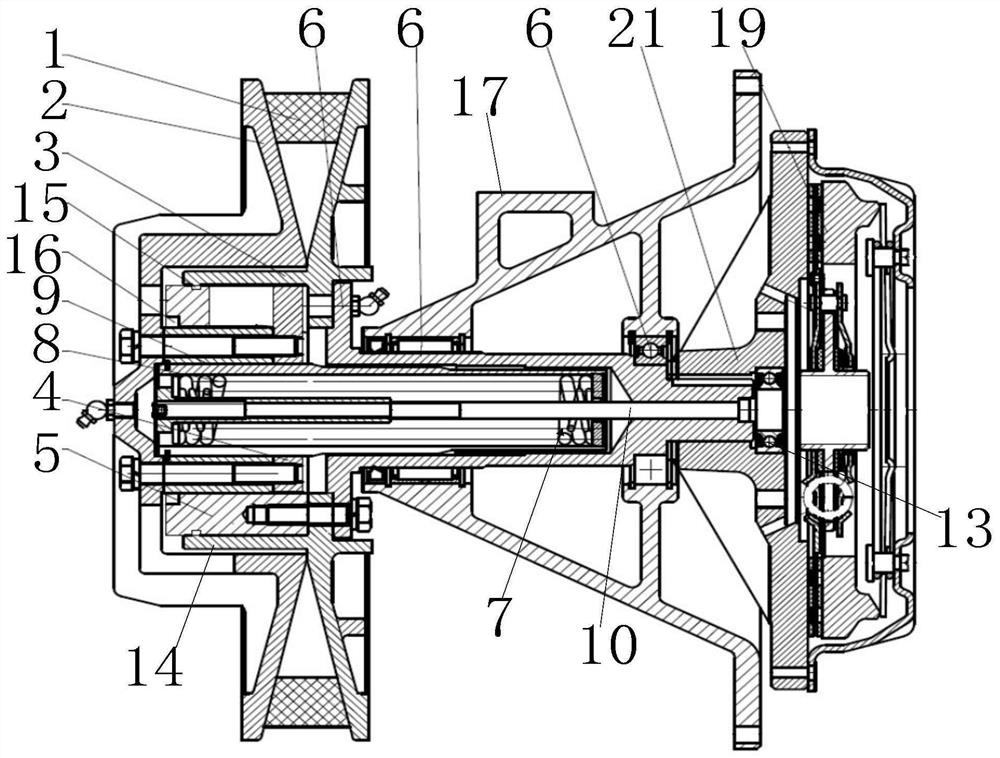

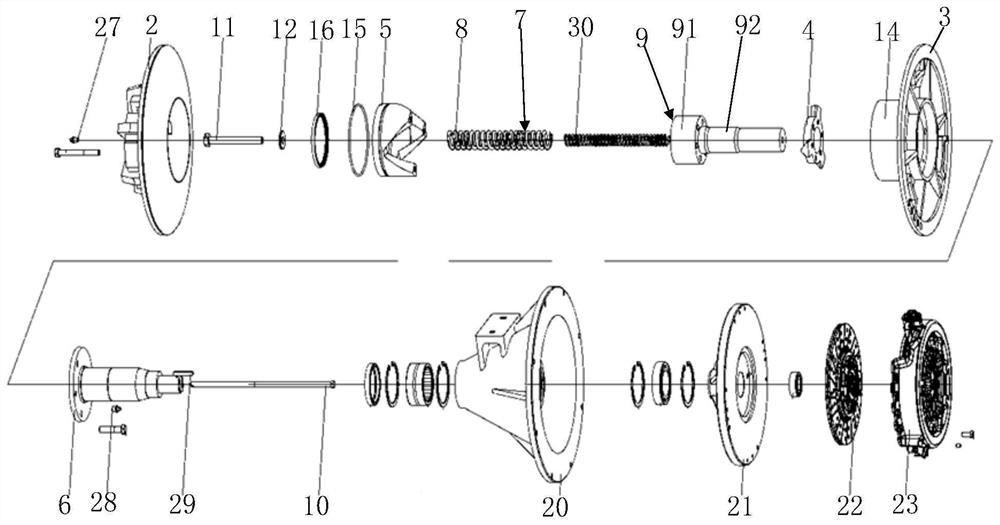

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

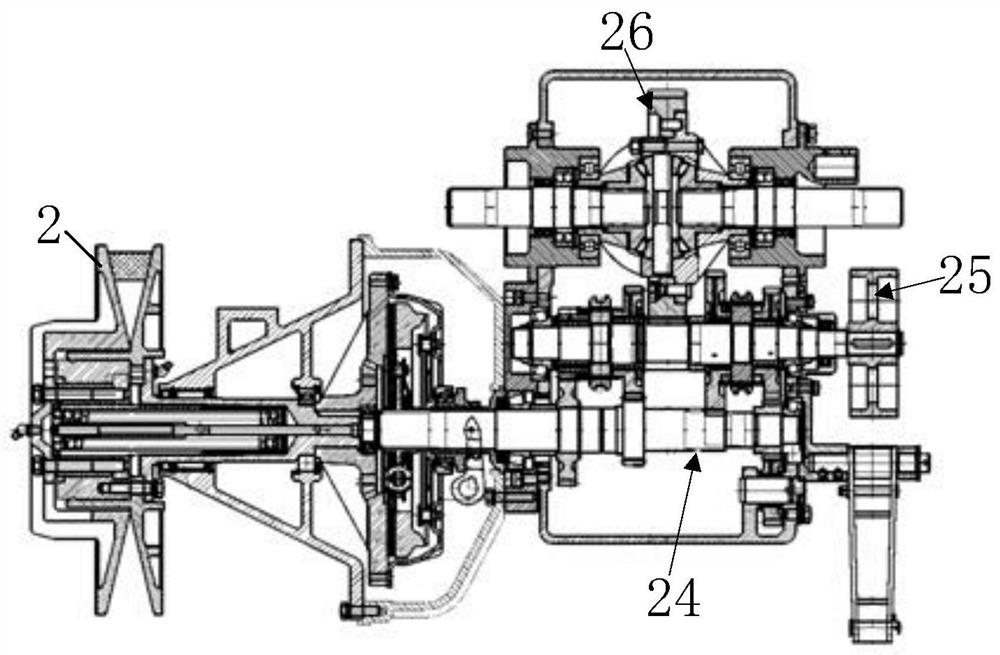

[0028] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a transmission, which includes: a moving plate 2 for achieving a gear ratio through axial movement, a fixed plate 3 for transmitting power to a gear transmission mechanism, and a fixed plate for meshing with the fixed plate The sliding cam 4 that transmits the rotating power of the moving plate to the fixed plate, the fixed cam 5 used to engage with the moving plate and receive the rotating power of the fixed plate, the elastic member 7 used to reset the relative position of the moving plate and the fixed plate, and the Based on the bracket 17 supporting the fixed disk and the input shaft assembly 6 used to transmit the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com