A winding coating machine

A coating machine and coating chamber technology, applied in the field of winding vacuum coating, can solve the problems of the influence of flexible film winding coating, unfavorable high-efficiency production scheduling plan, low work efficiency, etc., so as to improve the continuity of production links and production efficiency, Save the non-coating work process cycle, realize the effect of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are further described below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

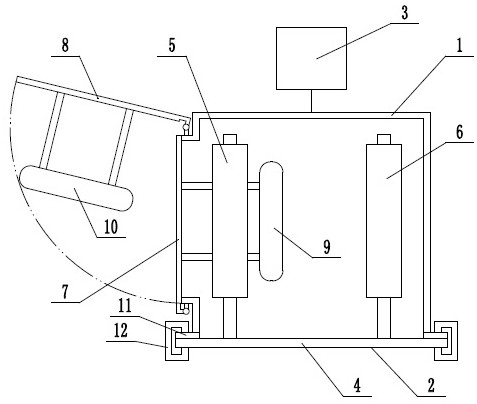

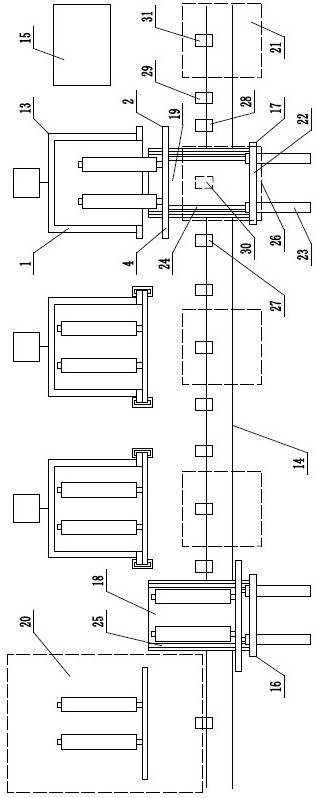

[0031] figure 1 It is a top-view structural schematic diagram of an embodiment of the winding coating machine of the present invention. As shown in the figure, a winding coating machine of the present invention mainly includes a coating chamber 1 , a mobile winding system unit 2 and a vacuum system 3 ; The mobile winding system unit 2 is sealed with the coating chamber 1 to form a vacuum chamber; the mobile winding system unit 2 includes a wall plate 4 and a winding system arranged on the wall plate, and the winding system includes a winding roller 5 and unwinding roller 6. The coil coating machine also includes a coating chamber door 7 and a coating chamber door 8, and the two coating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com