Steel formwork cleaning method and steel formwork cleaning cement mortar

A cleaning method and cement mortar technology, which is applied in the field of construction engineering, can solve the problems of difficult cleaning of pollutants on the surface of steel formwork, hidden dangers to human health and safety, and large environmental pollution, etc., to achieve increased mechanical occlusal force, increased bonding area, and clean high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

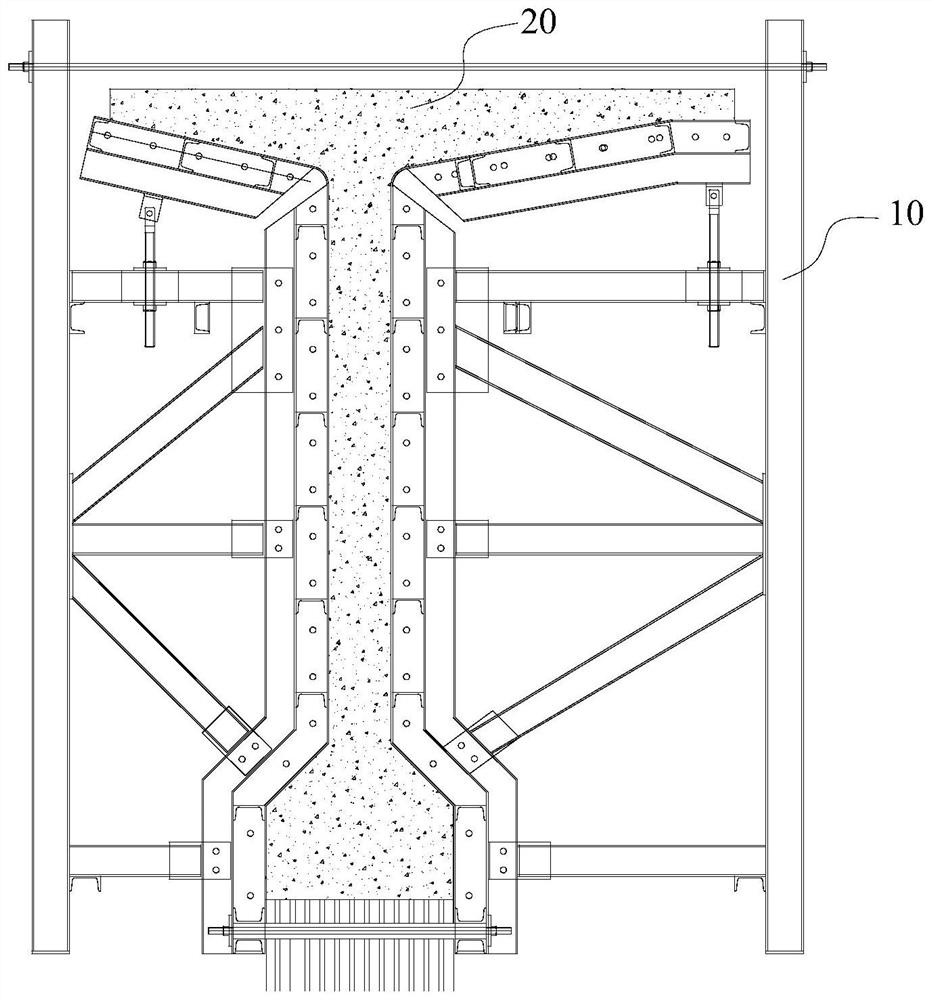

[0123] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention provides a kind of T-beam steel template cleaning method, comprises the following steps:

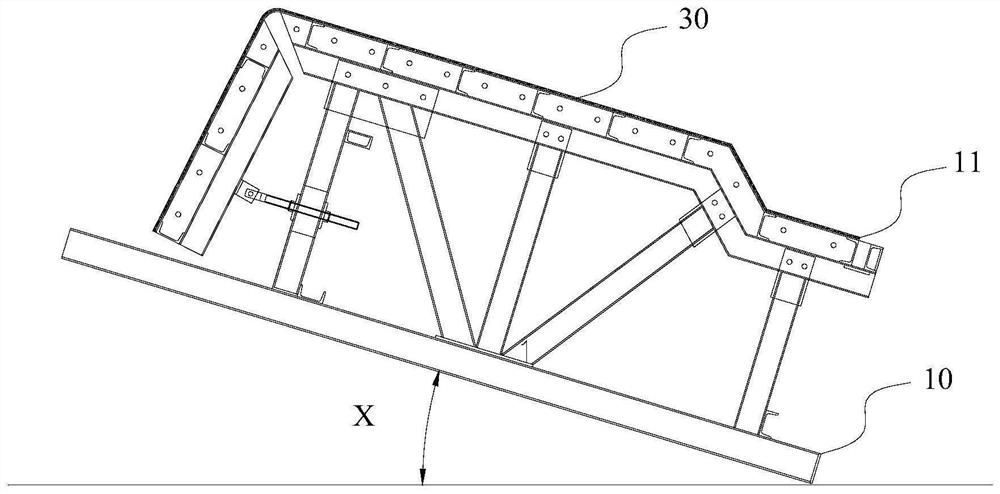

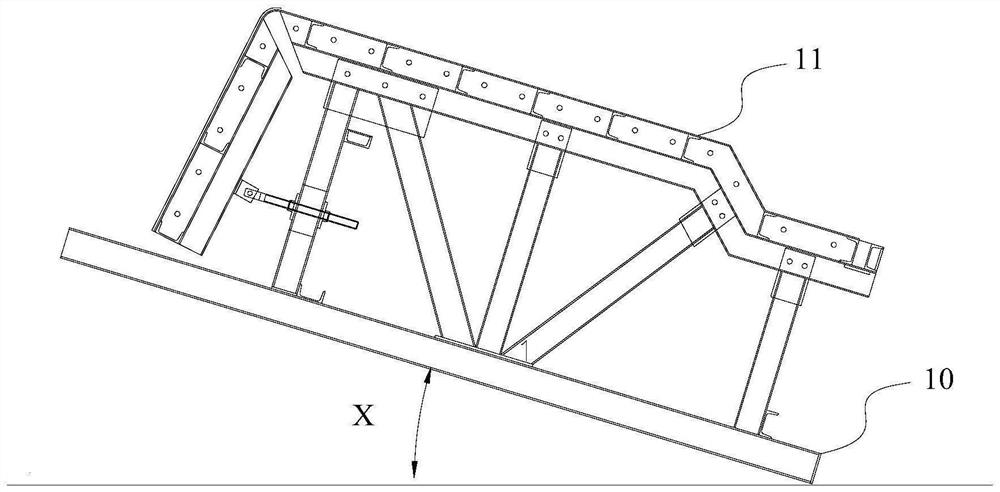

[0124] Step 501, please refer to figure 2 Place the T-beam steel formwork 10 to be cleaned at an oblique angle of 10° to the horizontal plane, with the surface 11 of the T-beam steel formwork facing upward. That is, the inclination angle X between the T-beam steel formwork 10 and the horizontal plane is 10 degrees.

[0125] Step 502, wet the surface 11 of the T-beam steel formwork with tap water with a pressure of 1.2Mpa.

[0126] Step 503, prepare cement mortar, and mix the following ingredients evenly according to the mass ratio: water 390, ordinary Portland cement 375 with a strength grade of 42.5, fly ash 80, sand with a fineness modulus of 2.0 1140, clay 70, and Water agent 3.0, expansion agent 90. The consistency of the prepared cement mortar is 140mm.

[0127] Step 504, please refer to fig...

Embodiment 2

[0131] Please refer to Figure 1 to Figure 3 , Embodiment 2 of the present invention provides a method for cleaning T-beam steel formwork 10, comprising the following steps:

[0132] Step 601, please refer to figure 2 Place the T-beam steel formwork 10 to be cleaned at an oblique angle of 30° to the horizontal plane, with the surface 11 of the T-beam steel formwork facing upward. That is, the inclination angle X between the T-beam steel formwork 10 and the horizontal plane is 30 degrees.

[0133] Step 602, wet the surface 11 of the T-beam steel formwork with tap water with a pressure of 0.1Mpa.

[0134] Step 603, prepare cement mortar, and mix the following ingredients evenly according to the mass ratio: water 400, ordinary portland cement 360 with a strength grade of 52.5, fly ash 105, sand with a fineness modulus of 1.6 1010, and silty soil 70 , Water reducing agent 3.2, expansion agent 130. The consistency of the prepared cement mortar is 170mm.

[0135] Step 604, ple...

Embodiment 3

[0139] Please refer to Figure 1 to Figure 3 , Embodiment 3 of the present invention provides a method for cleaning T-beam steel formwork 10, comprising the following steps:

[0140] Step 701, please refer to figure 2 Place the T-beam steel formwork 10 to be cleaned at an oblique angle of 20° to the horizontal plane, with the surface 11 of the T-beam steel formwork facing upward. That is, the inclination angle X between the T-beam steel formwork 10 and the horizontal plane is 20 degrees.

[0141] Step 702, wet the surface 11 of the T-beam steel formwork with tap water with a pressure of 0.7Mpa.

[0142] Step 703, prepare cement mortar, and mix the following ingredients evenly according to the mass ratio: water 420, ordinary portland cement 345 with a strength grade of 42.5, fly ash 80, sand with a fineness modulus of 1.6 1110, dust 90, Water reducer 4.0, expansion agent 90. The consistency of the prepared cement mortar is 120mm.

[0143] Step 704, please refer to figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com