Preparation method of reusable TPU degreasing cloth

A technology of oil stains and fabrics, applied in the field of TPU, can solve the problems of losing the function of removing oil stains, falling surfactants, and inability to use for a long time, achieving long service life, avoiding falling off, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a kind of preparation method of reusable TPU degreasing dirt cloth, and this preparation method comprises:

[0030] In the first stage, an amphiphilic (hydrophilic and lipophilic) prepolymer is prepared:

[0031] Step 1. Put the long-chain surfactant, isocyanate, antioxidant, anti-yellowing agent and catalyst into the reaction vessel, raise the temperature to 85-95°C, and stir for more than 2 hours;

[0032] Step 2. Raise the temperature to 115-125°C and react for more than 0.5h to obtain the amphiphilic prepolymer;

[0033] The second stage, preparing TPU:

[0034] Step 3. Put the polymeric diol, amphiphilic prepolymer, 1,4BG (1,4 butanediol), isocyanate, antioxidant, anti-yellowing agent and catalyst into the reaction vessel, raise the temperature to 75-85°C, and stir More than 0.3h;

[0035] Step 4. Baking the material, the baking temperature is 95-105°C, and the baking time is more than 7 hours;

[0036] Step 5, after cooling, the ...

Embodiment 1

[0060] A kind of preparation method of reusable TPU degreasing cloth, this preparation method comprises:

[0061] The first stage, preparation of amphiphilic prepolymer:

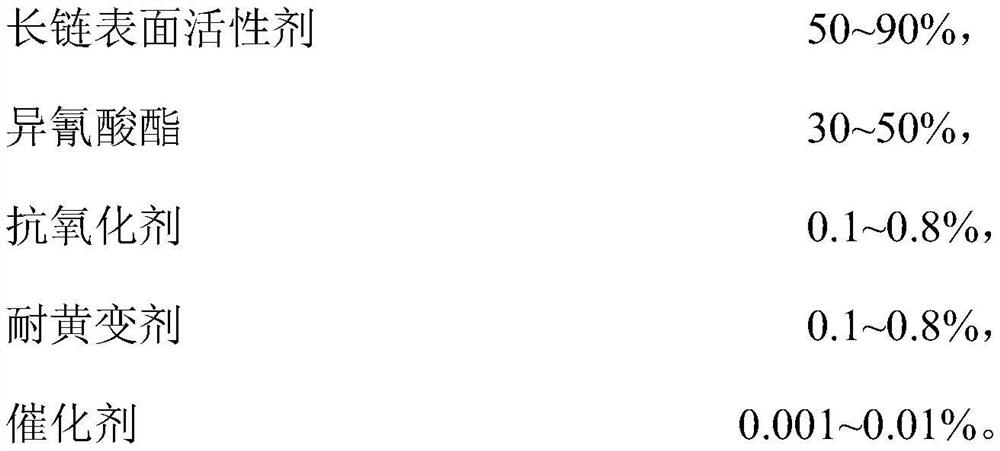

[0062] Prepare the components according to the following weights:

[0063]

[0064]

[0065] Step 1. Put sodium 2,5-dihydroxy-4-n-dodecylbenzenesulfonate, MDI, 1010 antioxidant, UV-P and stannous octoate into a reaction vessel, raise the temperature to 90°C, and stir for 3 hours;

[0066] Step 2, heating up to 120°C and reacting for 1 hour to obtain an amphiphilic prepolymer;

[0067] The second stage, preparing TPU:

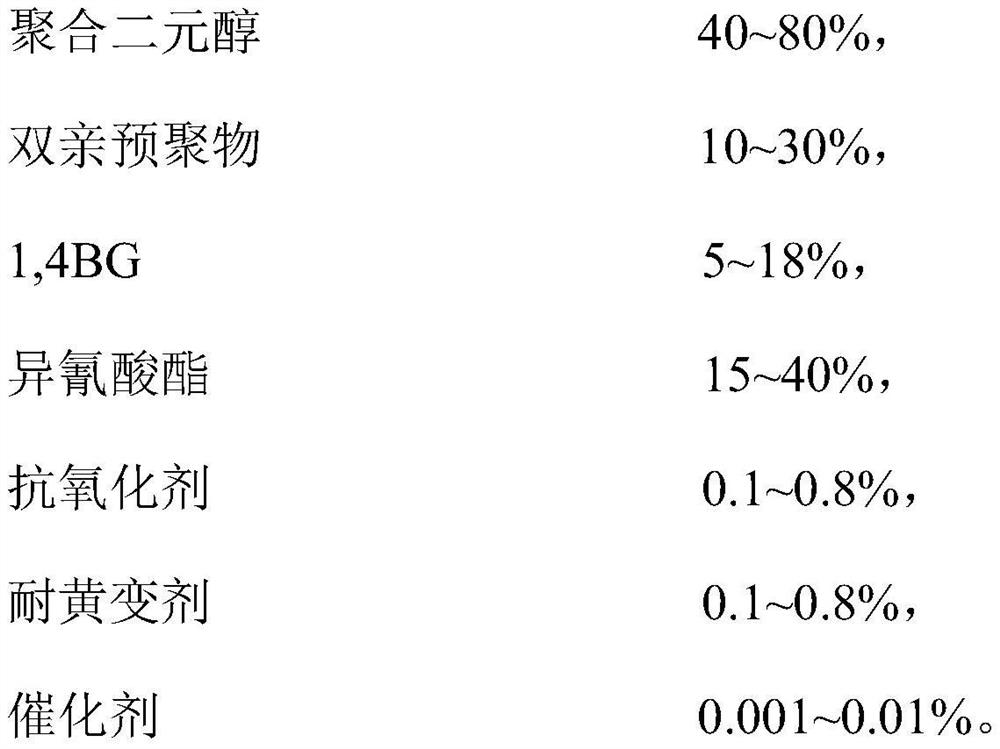

[0068] Prepare the components according to the following weights:

[0069]

[0070] Step 3. Put PEG-PPG copolymer, amphiphilic prepolymer, 1,4BG, MDI, 1010 antioxidant, UV-328 and stannous octoate into the reaction vessel, raise the temperature to 80°C, and stir for 0.5h;

[0071] Step 4. Pour the material on the tray coated with release agent, then put the tray into the oven, and...

Embodiment 2

[0078] A kind of preparation method of reusable TPU degreasing cloth, this preparation method comprises:

[0079] The first stage, preparation of amphiphilic prepolymer:

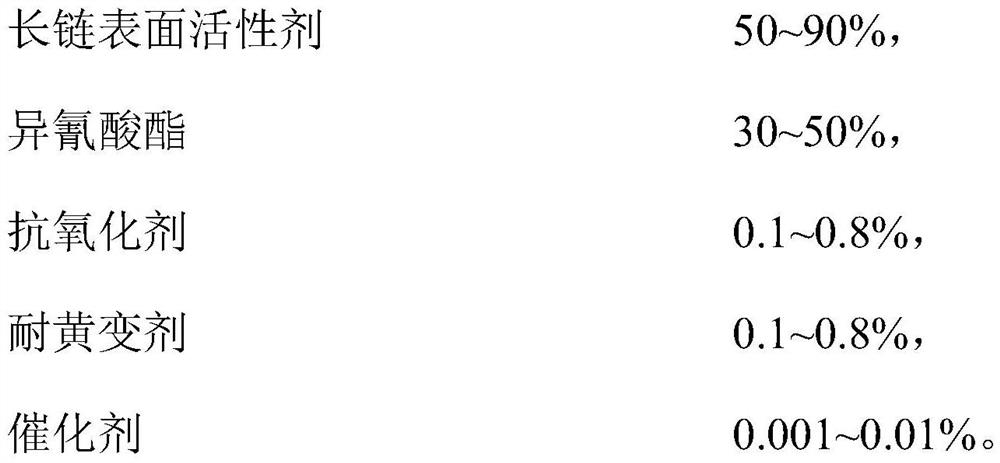

[0080] Prepare the components according to the following weights:

[0081]

[0082] Step 1. Put fatty alcohol polyoxyethylene ether, MDI, 1010 antioxidant, UV-P and stannous octoate into the reaction vessel, raise the temperature to 90°C, and stir for 3 hours;

[0083] Step 2, heating up to 120°C and reacting for 1 hour to obtain an amphiphilic prepolymer;

[0084] The second stage, preparing TPU:

[0085] Prepare the components according to the following weights:

[0086]

[0087]

[0088] Step 3. Put PEG, amphiphilic prepolymer, 1,4BG, MDI, 1010 antioxidant, UV-328 and stannous octoate into the reaction vessel, raise the temperature to 80°C, and stir for 0.5h;

[0089] Step 4. Pour the material on the tray coated with release agent, then put the tray into the oven, and bake the material at 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com