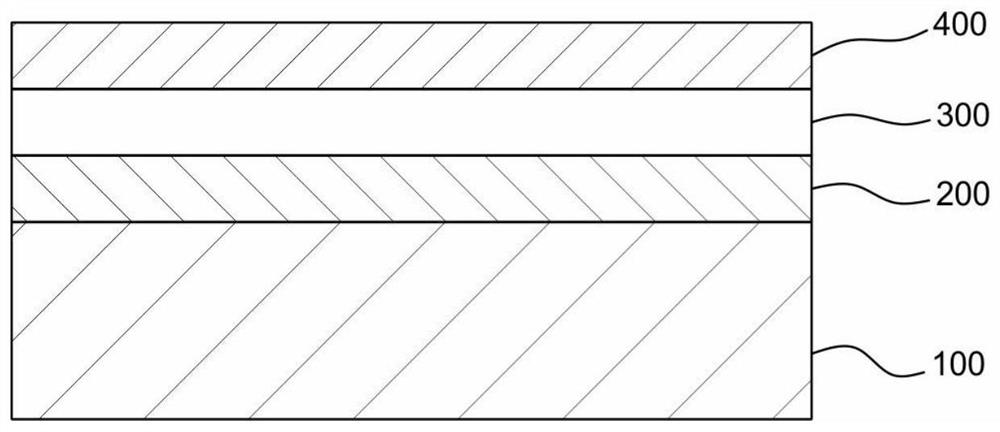

Multifunctional organic thin-film laser device, preparation method and application thereof

A technology of organic thin films and laser devices, which is applied to laser components, lasers, phonon exciters, etc., can solve the problems of inability to achieve selective output, difficult tuning methods, complicated operation and preparation processes, etc., and achieve good light cycle and energy Cycling stability, output wavelength tunable, low threshold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

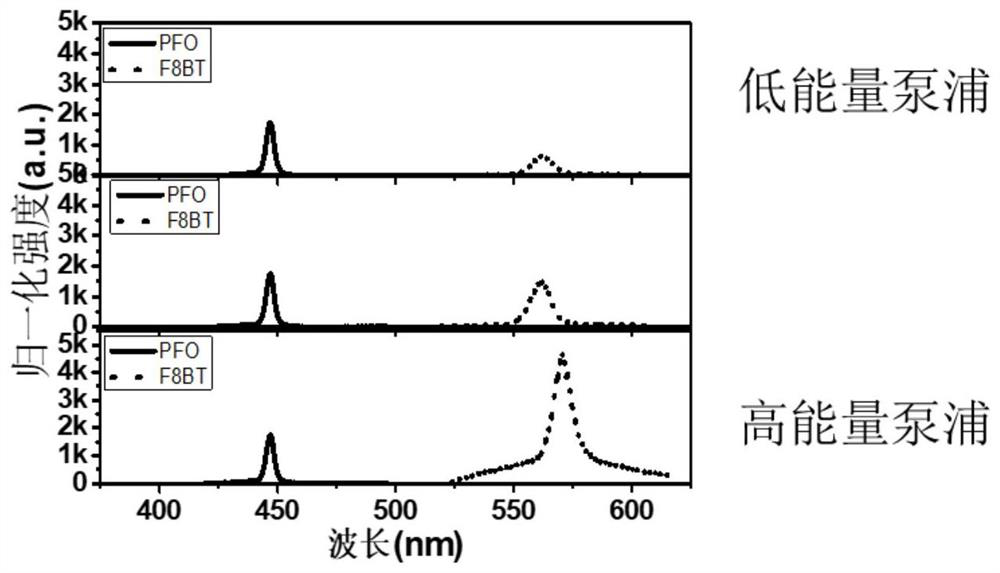

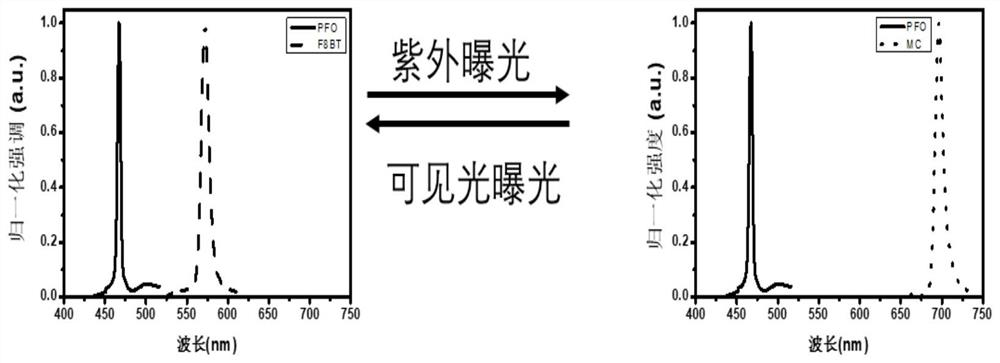

[0040] (1) Choose a quartz plate as the substrate, select poly[(9,9-dioctylfluorene)] (PFO) as the fluorescent compound with stable laser output in the blue light band, and select the fluorescent compound that meets the Foster energy transfer condition as [ (9,9-Di-n-octylfluorenyl-2,7-diyl)-alt-(benzo[2,1,3]thiadiazole-4,8-diyl)](F8BT), photoinduced The color-changing compound is spiro[1,3,3-trimethylindolechroman] (SP), and the water-soluble polymer material is polyvinyl alcohol (PVA);

[0041] (2) Dissolve F8BT and SP respectively in toluene solvent and heat and stir to fully dissolve the materials. The bottle containing SP solution is wrapped with a layer of tin foil to prevent the influence of light. The concentration of F8BT solution is 20mg / mL, and the concentration of SP solution is 20mg / mL; F8BT solution and SP solution are mixed, and the mass ratio of SP in the doping system is 20%, to obtain the first gain layer material;

[0042] (3) Deionized water is selected as...

Embodiment 2

[0049] The preparation method of Example 2 is the same as that of Example 1, and the mass ratios of SP in the doping system in the first gain layer material are 0%, 10%, 20%, 30%, 40%, 50%, 60%, carry out ASE test, the ASE threshold value under different doping concentration is as follows Figure 4 shown. Depend on Figure 4 It can be seen that when the mass ratio of SP in the doping system is 20%, the performance of the organic thin film laser device reaches the best.

Embodiment 3

[0051] (1) Choose a quartz plate as the substrate, choose poly[(9,9-dioctylfluorene)] (PFO) as the fluorescent compound with stable laser output in the blue light band, and choose poly[(9,9-dioctylfluorene)] (PFO) as the fluorescent compound that meets the Foster energy transfer conditions. [(9,9-dioctylfluorene)](PFO), the photochromic compound is spiro[1,3,3-trimethylindolechroman](SP), water-soluble polymer material Select polyvinyl alcohol (PVA);

[0052] (2) Dissolve PFO and SP in toluene solvent and heat and stir respectively, so that the materials are fully dissolved. The bottle with SP solution is wrapped with a layer of tin foil to prevent the influence of light. The concentration of PFO solution is 20mg / mL, and the concentration of SP solution is 20mg / mL; mix the PFO solution and the SP solution, and the mass ratio of SP in the doping system is 20%, to obtain the first gain layer material;

[0053] (3), (4) and (5) were completed according to the steps in Example 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com