Intelligent design method for automobile mold

An intelligent design, automotive mold technology, applied in design optimization/simulation, molding tools, manufacturing tools, etc., can solve the problems of harsh delivery cycle, repetitive work, and high workload of mold modification. To achieve the effect of improving the efficiency of design work, avoiding the cumbersome modification, reducing the heavy dependence on work experience and skill level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

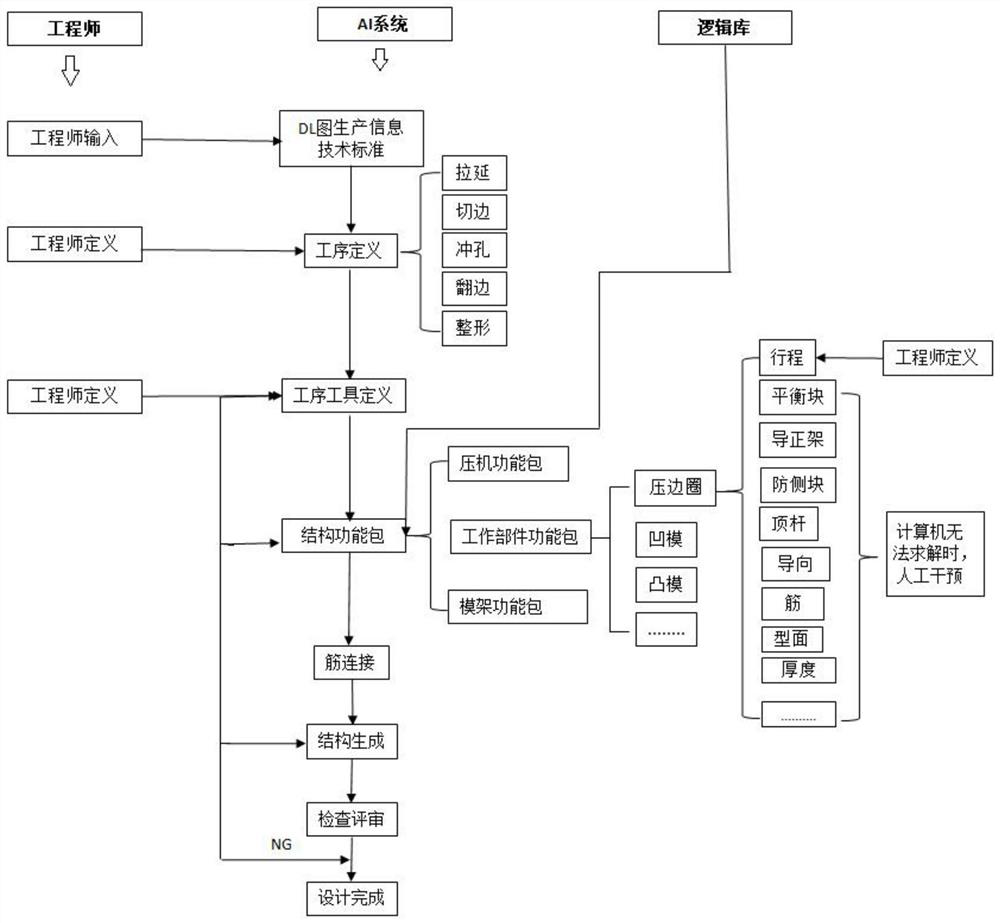

[0044] The automobile mold intelligent design method of the present invention comprises:

[0045] Step 1. Input the DL process plan diagram;

[0046] Step 2. Define the mold work content involved in each process according to the input DL process plan diagram;

[0047] Step 3. Define the content of each process in the DL process plan diagram into the corresponding tool body;

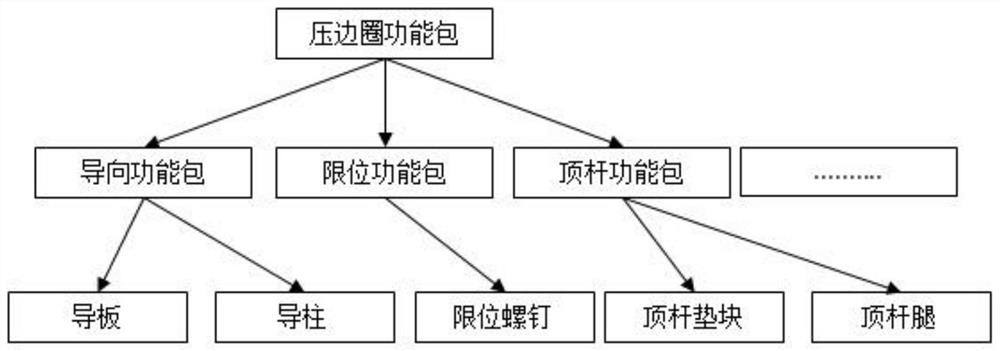

[0048] Step 4. Call the corresponding function package according to the selected process tool to generate the corresponding working parts;

[0049] Step 5. Connect the generated working parts to form a mold structure.

[0050] In step 1, it also includes inputting production information and technical standards.

[0051] In step 1, the DL process plan diagram includes information on products, process planes, process lines, and baselines required by each process; the production information includes production presses, mold length, width, and height, and installation locations; the technical standards inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com