A method of improving the overall pose accuracy of components by optimizing and constructing measurement points

A technology of measuring points and components, applied in the direction of measuring devices, instruments, etc., can solve problems affecting the overall accuracy, position deviation, etc., and achieve the effect of improving work efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The component in this embodiment is an aircraft panel, which is composed of a skin 1 and a long stringer 2 . Wherein, the material of the skin 1 is a carbon fiber reinforced resin matrix composite material, and the material of the long stringer 2 is an aluminum alloy, and the two are assembled into an aircraft panel by screwing.

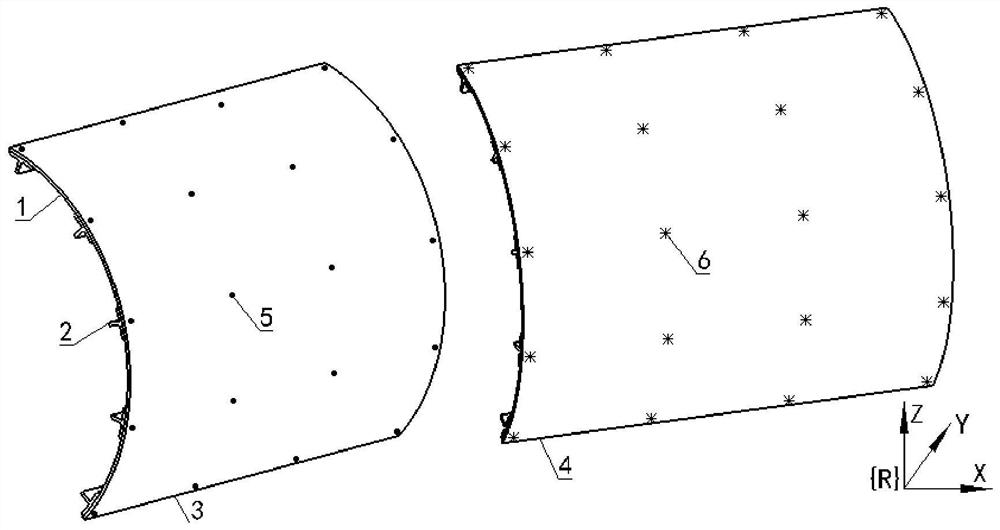

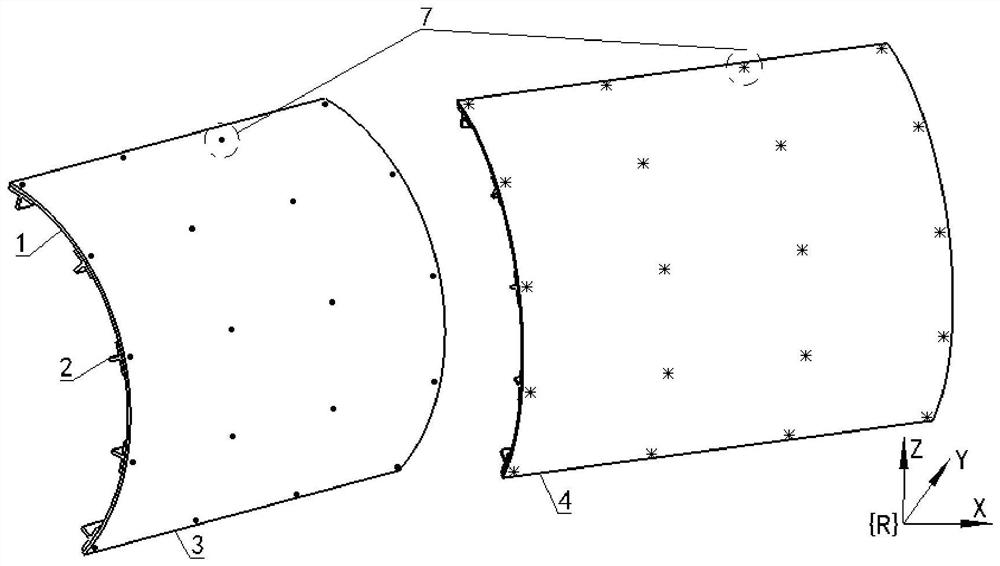

[0061] refer to figure 1 As shown, 20 measurement points are provided on the aircraft panel. figure 1 The left side is the aircraft panel 3 and the initial point 5 before the attitude adjustment and positioning, figure 1 The right side is the aircraft panel 4 and the target point 6 after the attitude adjustment and positioning. Due to factors such as the deformation of the aircraft panel, the positional relationship of the 20 initial points on the aircraft panel is definitely inconsistent with the positional relationship of the target point, that is: adjustment The 20 initial points 5 on the aircraft panel 3 before the attitude positioning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com