Safe mechanical trigger fuse for large-diameter explosive bullet head

A large-caliber, safe technology, applied in the direction of fuzes, collision fuzes, offensive equipment, etc., can solve the problems of bullet non-explosion-proof fuze safety hazards and other problems, and achieve the effect of solving trigger sensitivity, good trigger sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

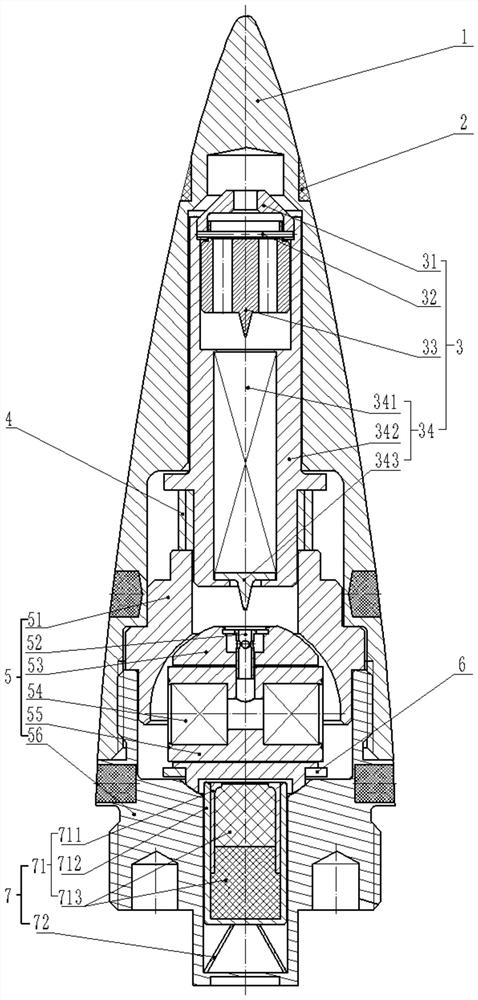

[0024] combine figure 1, a safe large-caliber explosive bullet warhead mechanical trigger fuze according to the present invention, including a casing 1, a shaping ring 2, a bump trigger and self-destruct mechanism 3, a soft belt 4, an explosion-proof and delayed release safety mechanism 5 , split ring 6, recoil safety mechanism and detonator 7. Wherein the shell 1 has an inner cavity from the bottom upwards, the impact trigger and self-destruct mechanism 3 and the explosion-proof and delayed release safety mechanism 5 are arranged coaxially along the inner cavity from top to bottom, and one end of the explosion-proof and delayed release safety mechanism 5 It is fixed in the inner cavity, and the other end extends out of the inner cavity. The shaping ring 2 is coaxially sleeved on the front section of the outer wall of the casing 1 . The impact trigger and self-destruct mechanism 3 includes a bracket 31 , a shear pin 32 and a first firing pin 33 . The soft belt 4 is a safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com