Multi-tube laser conduction illumination system adopting echo infrared detection

An infrared detection and lighting system technology, applied in the field of multi-tube laser conduction lighting systems, can solve the problems of incomplete energy release, lighting system damage, fire surrounding substances, etc., to improve light extraction efficiency, save construction costs, and reduce laser loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

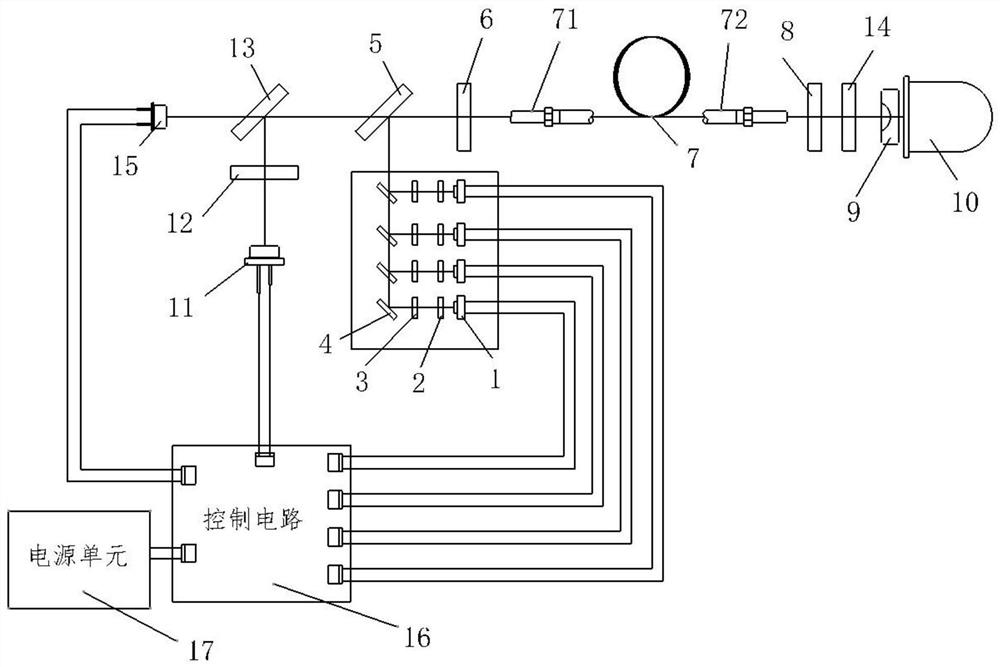

[0025] The reference signs in the drawings of the specification include: 1. Blue light LD; 2. Shaping lens; 3. First collimating lens; 4. Reflecting mirror; 5. First filter system; 6. Coupling lens; 7. Transmission fiber ; 71, ceramic ferrule APC; 72, ceramic ferrule PC; 8, second collimating lens; 9, diffusion lens; 10, fluorescent cap; 11, infrared LD; 12, third collimating lens; 13, second Filter system; 14. Third filter system; 15. Photoelectric element PD; 16. Control circuit; 17. Power supply unit.

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com