Skeleton type air-blowing composite optical cable

A composite optical cable and skeleton technology, which is applied in the direction of power cables, cables, and optics including optical transmission components, can solve problems such as electric shock, high construction requirements, and high installation costs, and achieve simplified installation procedures, lower laying costs, and lower installation costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

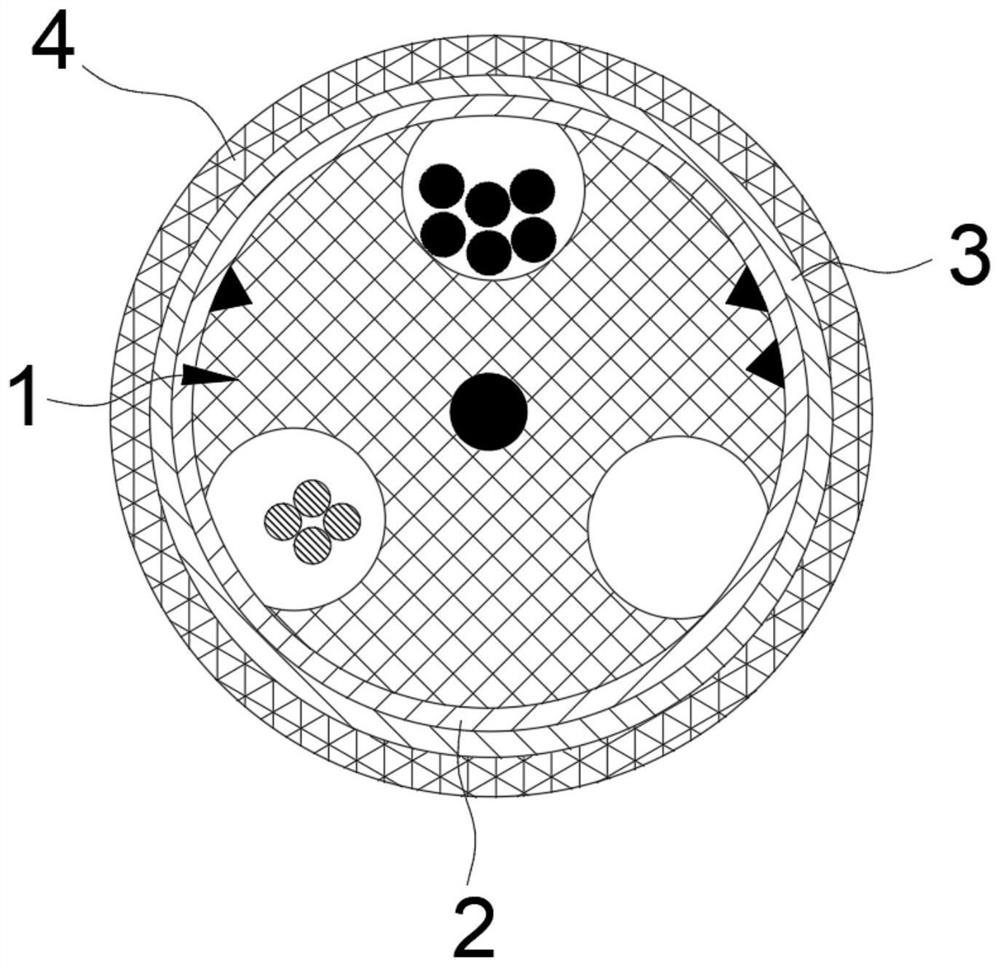

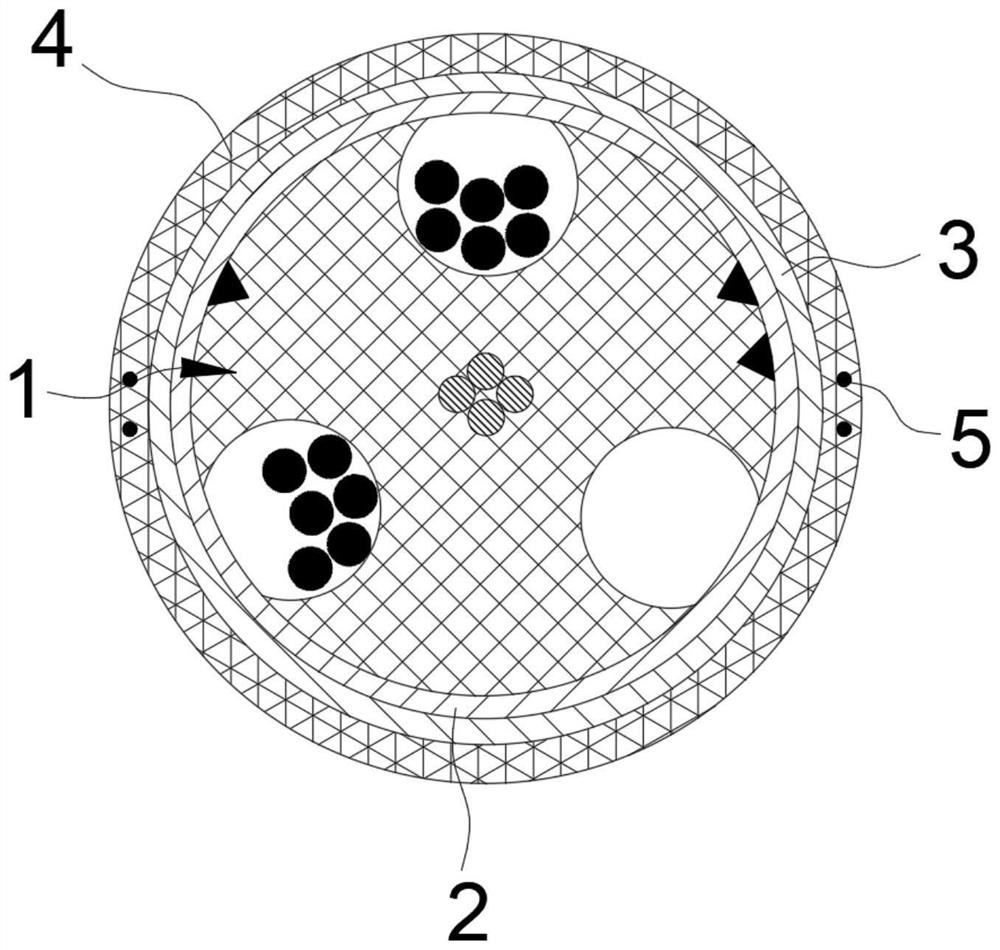

[0053] In the preparation process of the composite optical cable, after the laying of the cable in the first skeleton groove 101 is completed, a water blocking layer 2 is preferably formed on the outer periphery of the skeleton 1, and a reinforcing layer and / or The armor layer 3 accurately encapsulates the cables in the first skeleton slot 101 to ensure the water resistance and damage resistance of the composite optical cable in practical applications. In a preferred embodiment, the water-blocking layer 2 is formed by winding the water-blocking tape on the outer periphery of the skeleton 1 in turn, the reinforcement layer is formed by winding and covering the outer periphery of the water-blocking layer in sequence with moisture-proof aluminum tape, and the armor layer 3 is formed by FRP tape in turn twisted. When the water-blocking layer 2 , the reinforcement layer and the armor layer 3 are provided at the same time, the reinforcement layer is arranged between the water-block ...

Embodiment 1

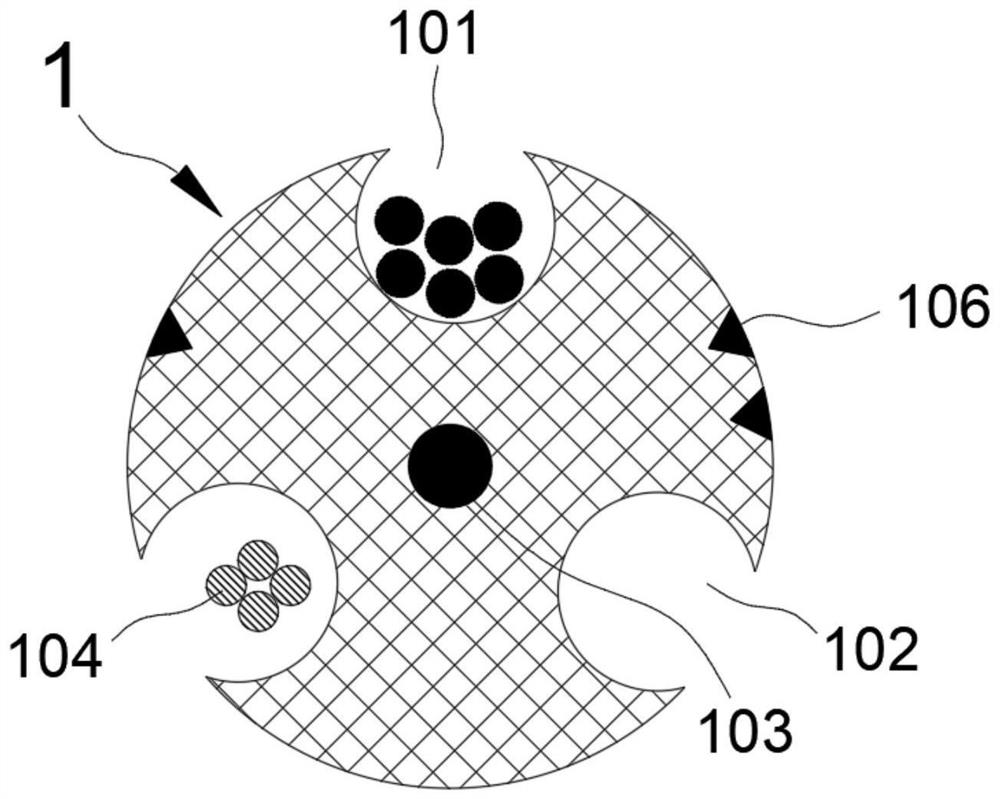

[0057] In this embodiment, in addition to the above-mentioned basic settings, the structure of the composite optical cable is also provided with a skeleton reinforcement 103 in the middle of the skeleton 1. The skeleton reinforcement 103 is a single-core or multi-core reinforcement wire, which extends longitudinally along the skeleton 1. According to actual needs, it can be made of metal materials such as steel wires and iron wires, or it can be made of hard non-metallic materials.

[0058] In actual operation, the skeleton 1 is formed by continuous extrusion molding on the periphery of the skeleton reinforcement 103, and then other corresponding structures are arranged in the skeleton 1 and outside the skeleton, and finally formed such as figure 1 Composite cable structure shown in .

Embodiment 2

[0060] In this embodiment, the difference between the structure of the composite optical cable and the above-mentioned basic structure is that: the middle part of the frame 1 is covered with a power line 104. At this time, the power line 104 does not need to be arranged in the first frame groove 101, and Corresponding signal lines and optical fiber units can be correspondingly accommodated.

[0061] Through the above-mentioned setting of the power line 104, the separation of the power line and other cables can be fully realized, and it is ensured that when the fiber optic cable is branched and the air blows the fiber optic cable, there is no need to cut off the power to the composite fiber optic cable, ensuring the reliability of the corresponding machine room, and minimizing Composite optical cable air blowing operation or optical fiber divergence will affect the work of other cables and equipment, and improve the application reliability of composite optical cable.

[0062] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com