Echo detection multi-tube laser conduction illumination system

A technology of echo detection and lighting system, applied in the field of lighting, can solve the problems of incomplete energy release, fire surrounding substances, lighting system damage, etc., and achieve the effect of improving light output efficiency, saving construction costs, and reducing the number of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

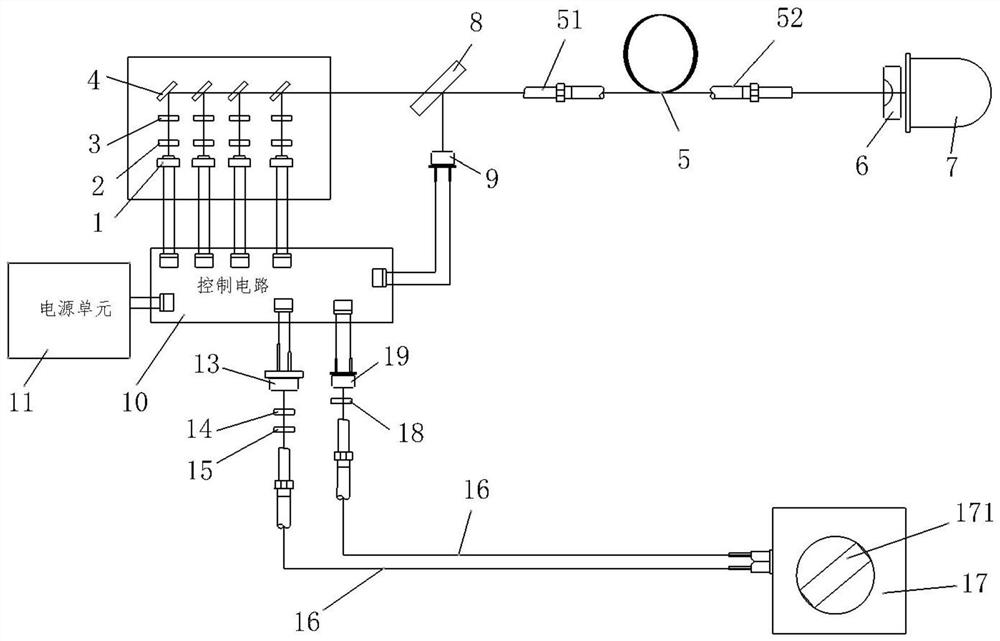

[0045] as attached figure 2 Shown: the first passive switch includes a first infrared LD13, a second collimating lens 14, a first coupling lens 15, a second transmission fiber 16, a first switching unit 17, a second coupling lens 18 and a second photoelectric element PD19 The red light irradiated by the first infrared LD13 enters the second transmission fiber 16 through the second collimating lens 14, the first coupling lens 15, and is transmitted to the first switch unit 17 through the second transmission fiber 16, and the first switch unit 17 is provided with a first reflective mirror 171, by adjusting the angle of the first reflective mirror 171 to control whether the red light of the first infrared LD 13 is reflected on the second photoelectric element PD 19; when the second photoelectric element PD 19 receives the first When the red light of an infrared LD 13 is on, the first passive switch 17 is in the on state, and when the second photoelectric element PD 19 cannot rec...

Embodiment 2

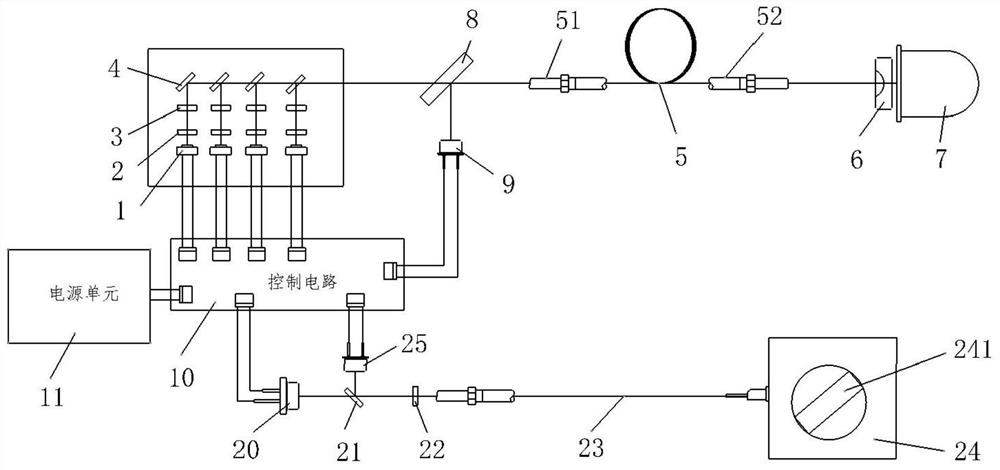

[0047] as attached image 3 Shown: the second passive switch includes a second infrared LD 20, a second filter system 21, a third coupling lens 22, a third transmission fiber 23, a second switch unit 24 and a third photoelectric element PD25; the second infrared LD20 The irradiated red light from the second filter system 21 and the third coupling lens 22 enters the third transmission fiber 23, and is transmitted to the second switch unit 24 through the third transmission fiber 23, and the second switch unit 24 is provided with a second Reflective mirror 241 controls whether the red light of the second infrared LD20 is reflected on the third photoelectric element PD25 by adjusting the angle of the second reflective mirror 241; when the third photoelectric element PD25 received the red light of the second infrared LD20, the second The second passive switch is in the open state, and when the third photoelectric element PD25 cannot receive the red light of the second infrared LD20...

Embodiment 3

[0050] The manual power switch 26 realizes the power-off and power supply of the echo detection multi-tube laser conduction lighting system of the present invention through the opening and closing of the manual control switch system, as attached Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com