Drum-type efficient diesel engine oil-gas separator

A technology for oil and gas separators and diesel engines, which is applied in the directions of machines/engines, mechanical equipment, engine components, etc., which can solve the problem of not being able to automatically adjust to ensure separation effect and pressure loss, limiting the versatility of different models and product series production, oil and gas separation. The position of the outlet of the device cannot be adjusted, which can increase the cost and manufacturing difficulty, avoid excessive air pressure loss, and avoid poor oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

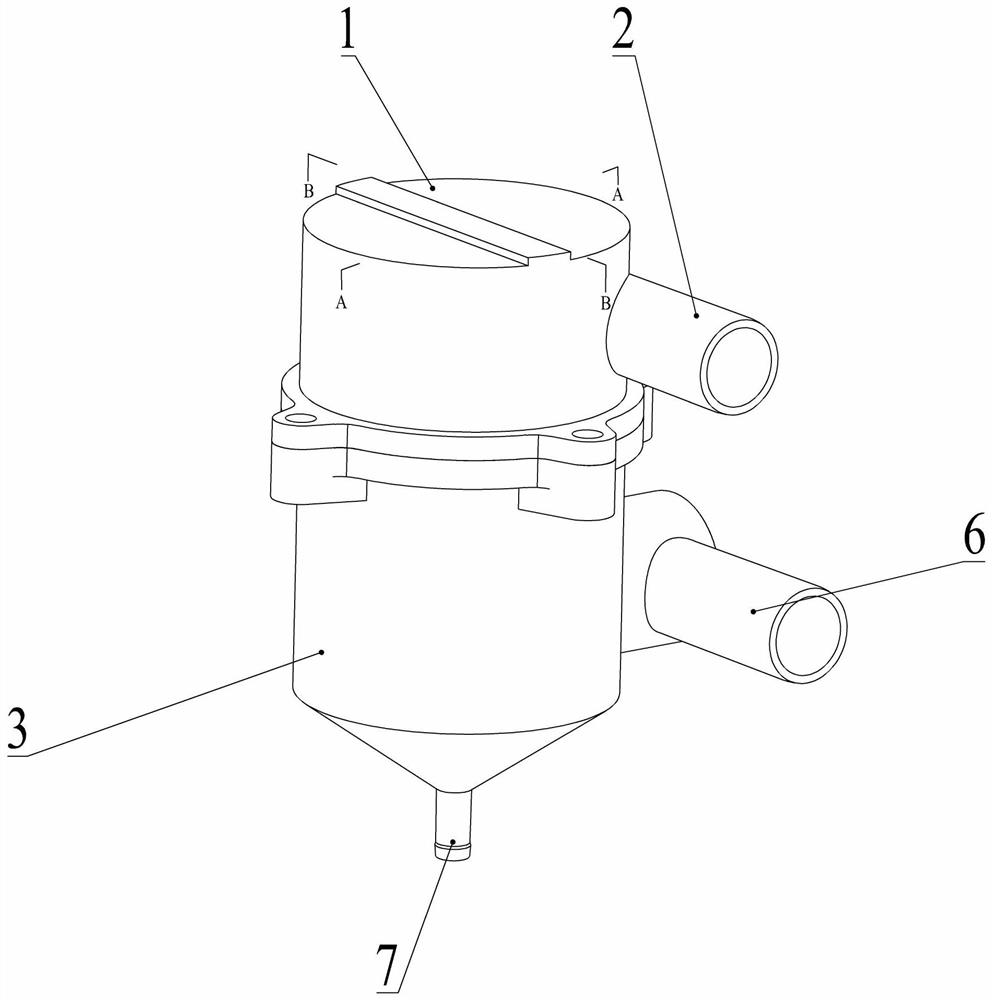

[0040] A drum-type high-efficiency diesel engine oil-gas separator includes an upper filter assembly and a lower filter assembly. Such as figure 1 As shown, during installation, the upper filter assembly and the lower filter assembly are rotatably connected, and after being adjusted to a suitable position, the relative positions of the upper filter assembly and the lower filter assembly are fixed by means of welding, bolts, etc.

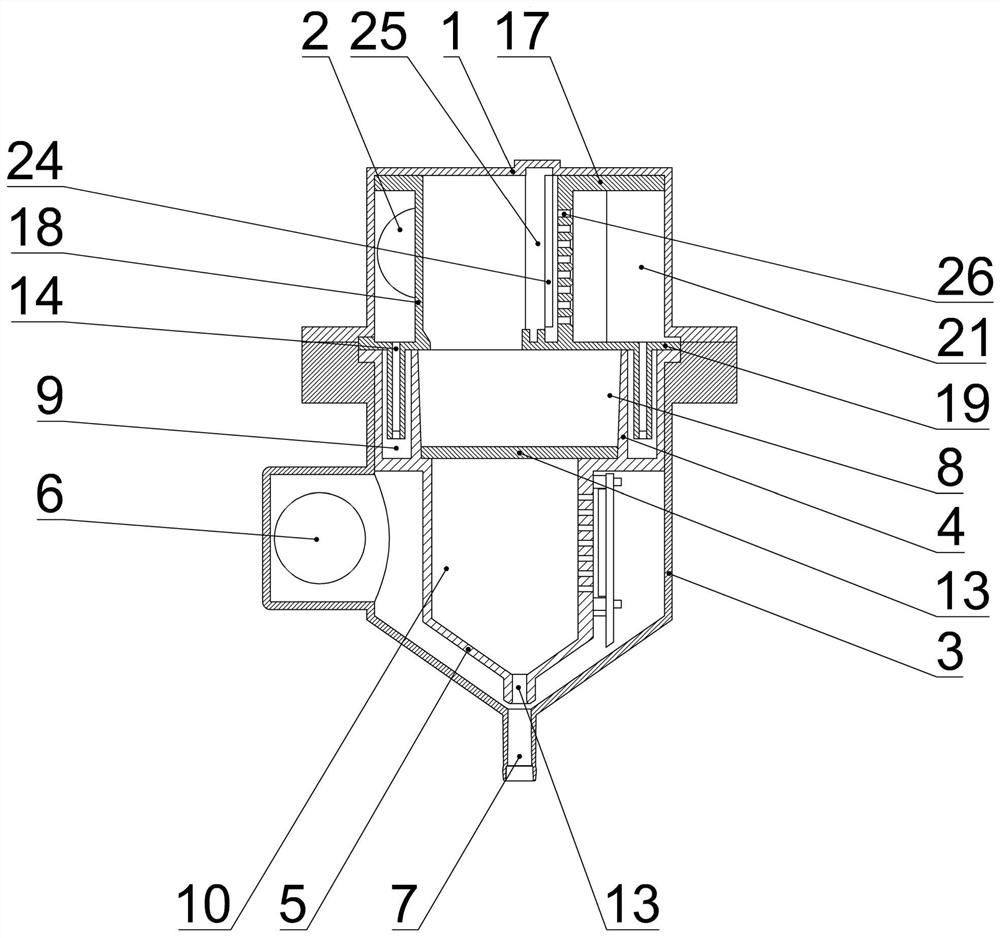

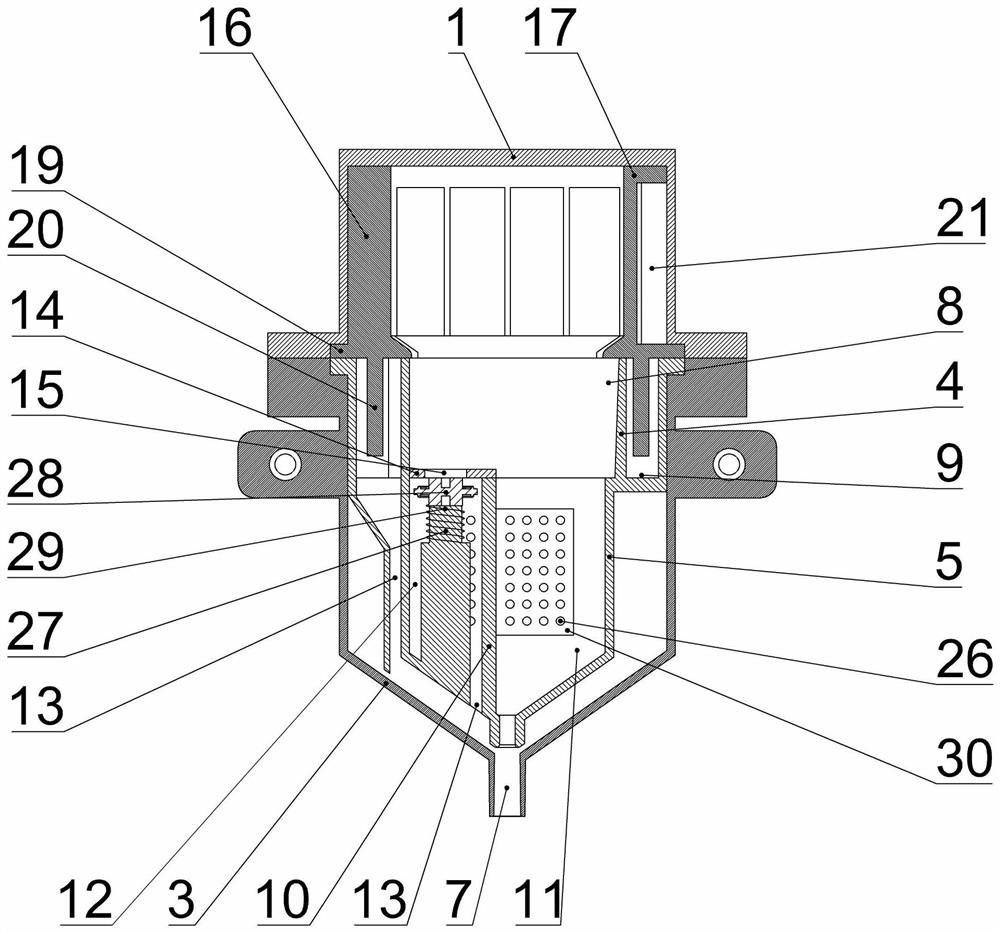

[0041] Such as figure 2 and image 3 As shown, the upper separation assembly includes an upper casing 1 and an upper filter part. The upper casing 1 is a cylindrical casing with a closed upper end surface and an open lower end surface, and an air intake duct 2 is fixedly connected to the side end surface, and the air intake duct 2 runs through the inner cavity of the upper housing 1 .

[0042] The upper fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com