Proppant laying visualization experiment device capable of dynamically adjusting seam width and using method thereof

A technology of dynamic adjustment and experimental equipment, which is applied in the field of oil exploration and research, can solve the problems of being unable to quantitatively characterize the pressure distribution characteristics of the metal plate surface, not combining the structural characteristics of the sanding device, and being unable to actively adjust the shape of the crack, so as to overcome the inlet size And the fixed position is not easy to adjust, the fluid loss rate can be controlled in real time, and the effect of overcoming the non-adjustable fluid loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

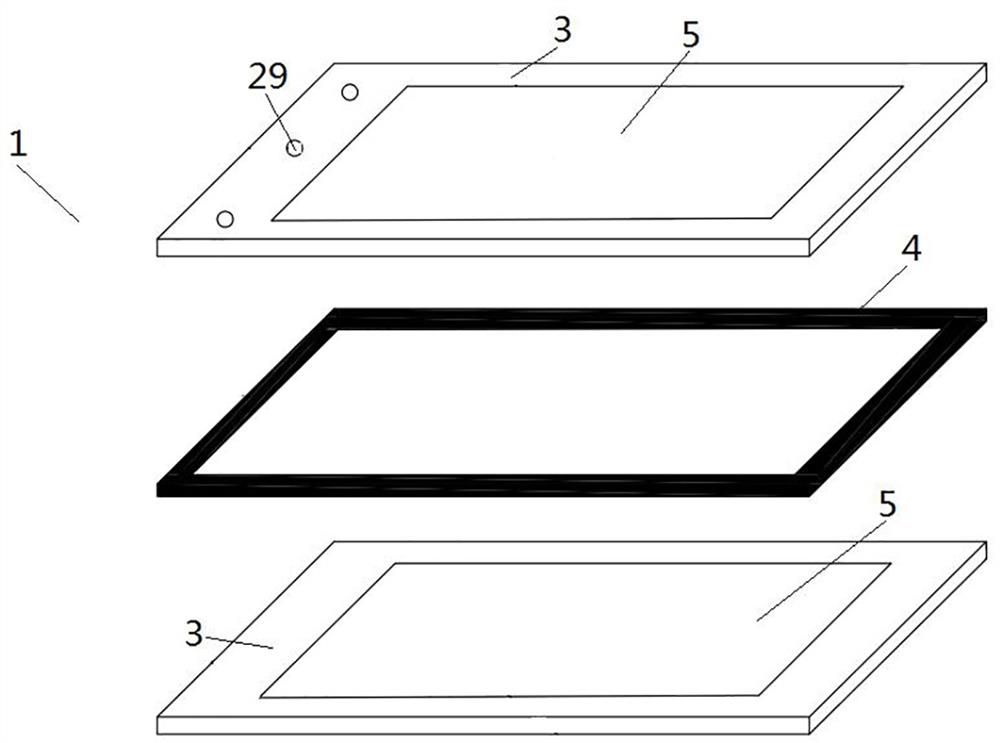

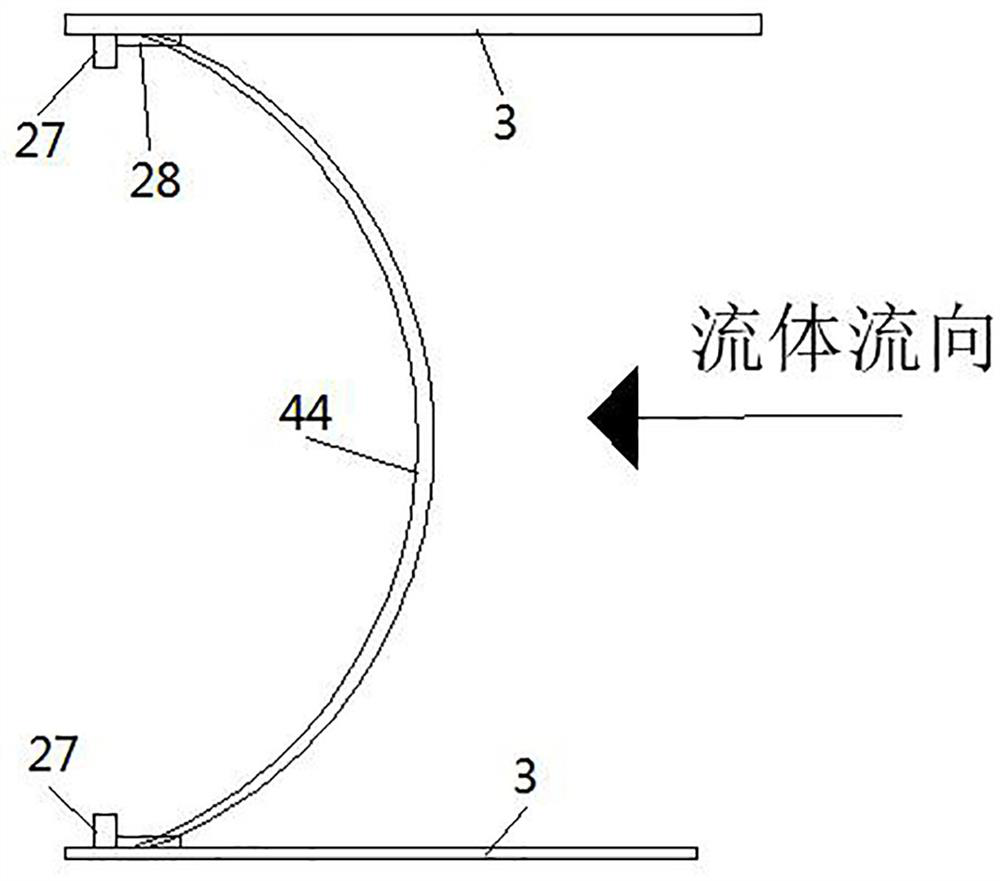

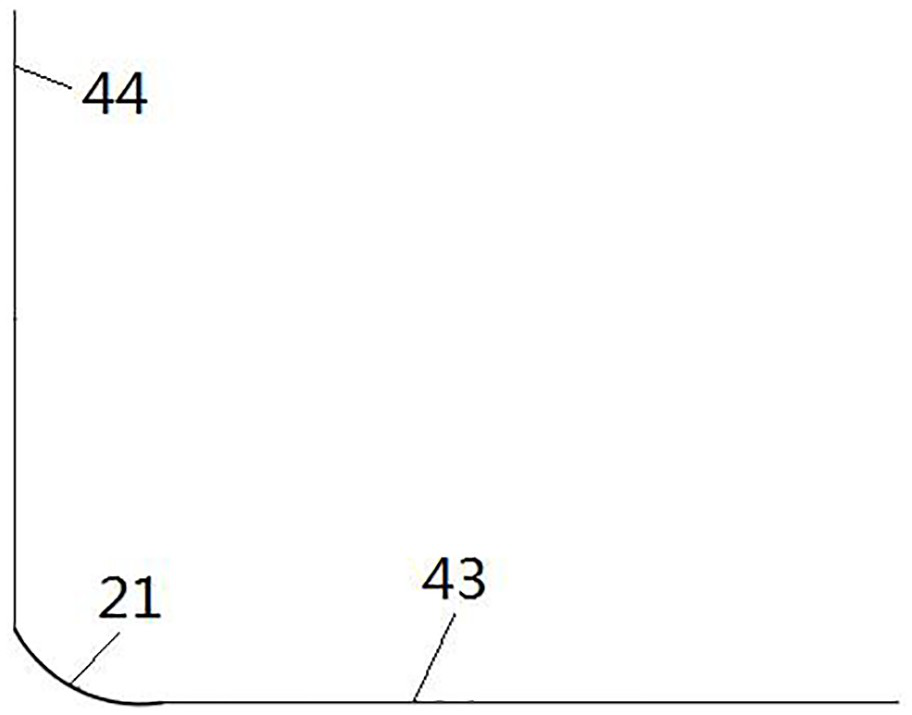

[0037] Embodiment 1, in this embodiment, if Figure 1 to Figure 5As shown, the proppant laying visualization experimental device for dynamically adjusting the fracture width includes a feeding mechanism, which is used to prepare and transport the sand mixing fluid; the discharge end of the feeding mechanism is connected with a visible flat plate crack, The cracks in the visualized plate are formed by the visualized plate 1, the visualized plate 1 is composed of two metal frames 3 and a seal 4, the seal 4 is arranged between the two metal frames 3, the metal Strengthened glass 5 is fixed in the frame of frame 3 ; a visible plate crack for simulating fracturing cracks is formed between the two visualized plates 1 , and the width of the visualized plate crack is regulated by a limit fixing mechanism 2 . In this embodiment, the metal frame 3 is made of stainless steel, and its frame width is 50mm. The size of the strengthened glass 5 is preferably 3m in length, 0.4m in height, and...

Embodiment 2

[0053] Embodiment 2 is different from Embodiment 1 in that: a filter loss plate is installed inside the strengthened glass 5, so that it is convenient to simulate the side filter loss effect.

[0054] A method for using a proppant laying visualization experimental device for dynamically adjusting the width of a seam, comprising the following steps:

[0055] First inject 300L of clear water into the sand mixing tank 8 and configure fracturing fluid, and use the stirring blade to make it fully mixed;

[0056] Step 1. Select steady-state or transient pump injection displacement in the controller, input the pump injection parameters, and the system automatically opens the valves of the liquid inlet pipeline 10 and the material preparation tank 7, so that fracturing fluid and support can be injected into the sand mixing tank 8 At the same time, turn on the stirring blade to stir, so that the fracturing fluid and proppant are evenly mixed;

[0057] Step 2, open the valve of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com