Well drilling device for oil exploitation

A drilling and oil technology, which is applied in the field of drilling equipment for oil development, can solve the problems of adjustment, inability to stabilize and quickly drive the height of components, and achieve the effects of improving stability, convenient and quick disassembly and connection, and stable height adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

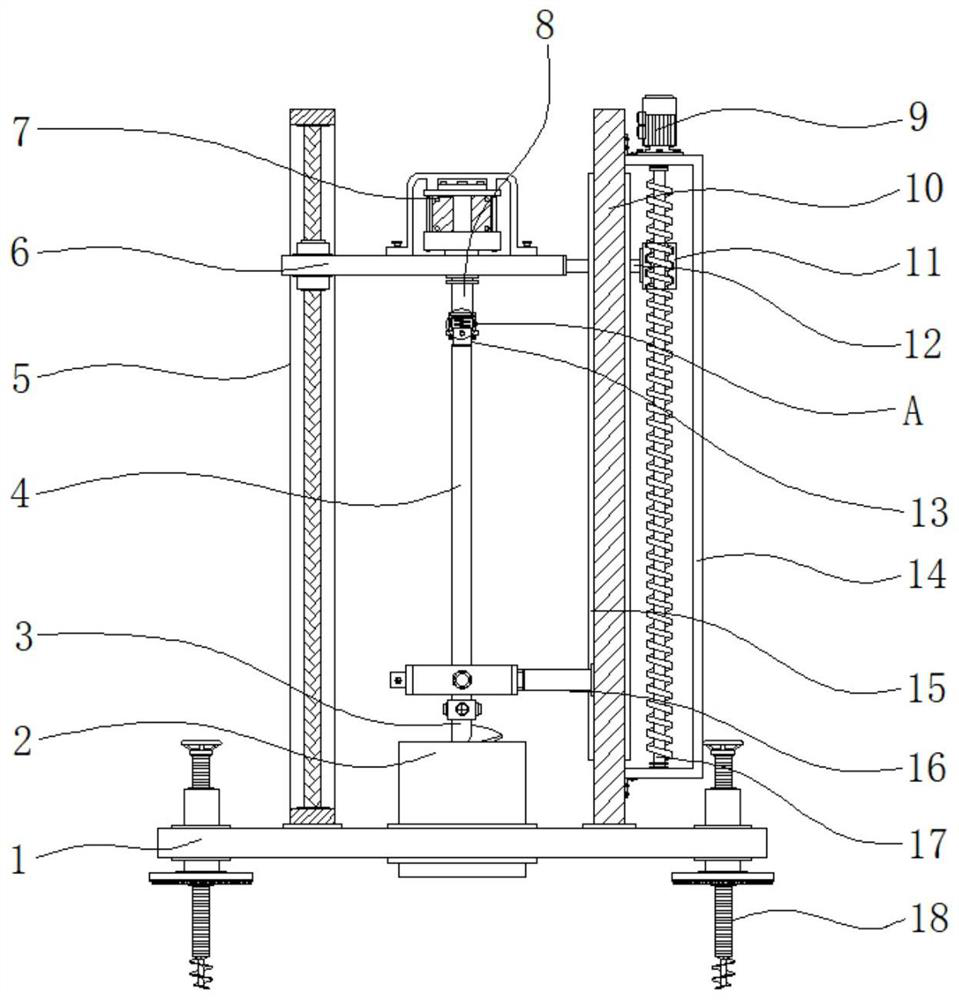

[0035] Example 1: see Figure 1-6 , a drilling device for oil exploitation, comprising a bottom plate 1, a cylinder 2 is inserted at the middle position of the top of the bottom plate 1, a fixed vertical plate 10 is fixedly connected to one side of the top of the bottom plate 1, and the top of one side of the fixed vertical plate 10 is provided with There is a top plate 6, one side of the top of the top plate 6 is fixedly connected with a drive motor 7, the model of this drive motor 7 can be Y90S-2, the output end of the drive motor 7 is fixedly connected with a drive shaft 8, and the bottom end of the drive shaft 8 penetrates the top plate. 6. The other side of the top of the bottom plate 1 is provided with a stabilizing structure 5, the bottom end of the drive shaft 8 is provided with a drill rod 4, the bottom end of the drill rod 4 is fixedly connected with a drill bit 3 through a coupling, and the bottom end of the drive shaft 8 and A dismounting structure 13 is arranged bet...

Embodiment 2

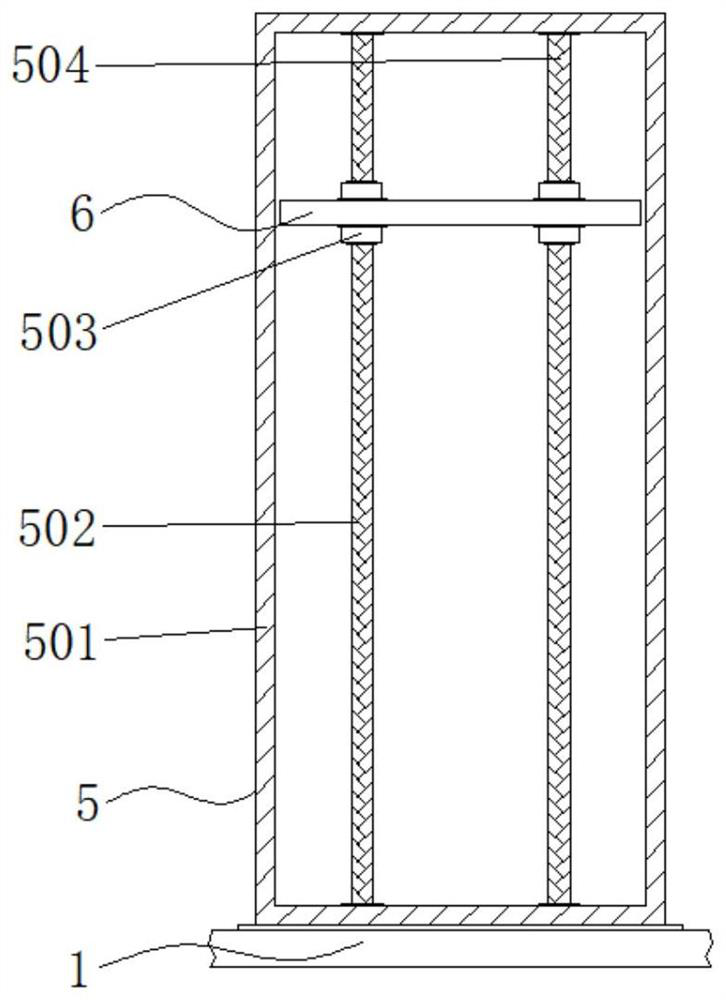

[0039] Embodiment 2: The stabilizing structure 5 is composed of a fixed frame 501, a first stabilizing column 502, a sliding sleeve 503 and a second stabilizing column 504. The fixing frame 501 is fixedly connected to the other side of the top of the bottom plate 1, and the inner ends of the fixing frame 501 are between two ends. The front end of the frame 501 is fixedly connected to the second stabilizing column 504, the rear end between the two inner ends of the fixed frame 501 is fixedly connected to the first stabilizing column 502, and the sliding sleeves 503 are respectively inserted at the two ends of the other side of the top of the top plate 6;

[0040] The first stabilizing column 502 and the second stabilizing column 504 penetrate through the inside of the sliding sleeve 503 respectively, and a sliding structure is formed between the first stabilizing column 502 and the second stabilizing column 504 and the sliding sleeve 503 respectively;

[0041] Specifically, as ...

Embodiment 3

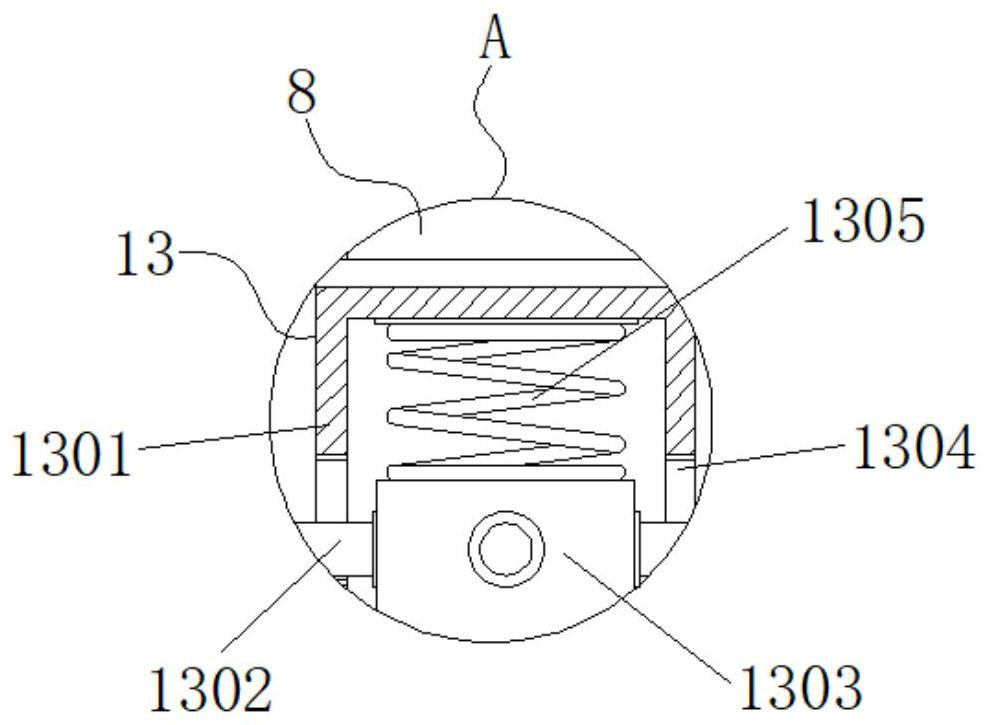

[0042] Embodiment 3: The disassembly structure 13 is composed of an installation groove 1301, a clamping rod 1302, an installation block 1303, a clamping groove 1304 and a compression spring 1305. The installation groove 1301 is fixedly connected to the bottom end of the drive shaft 8, and the installation block 1303 is fixedly connected to the drill. At the top of the rod 4, the outside of the installation groove 1301 is evenly provided with a clamping groove 1304, the outside of the installation block 1303 is evenly fixedly connected with a clamping rod 1302, and the top of the inside of the installation groove 1301 is fixedly connected with a compression spring 1305;

[0043] The clamping rod 1302 is provided with four groups, and the outside of the mounting block 1303 of the clamping rod 1302 is annularly distributed;

[0044] The clamping rods 1302 are respectively embedded in the interior of the clamping grooves 1304, and a clamping structure is formed between the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com