Water stop structure for post-cast strip

A post-casting belt and waterproof structure technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the leakage at the junction of new and old concrete in the post-casting belt, the gap between concrete and steel plate, and the poor anti-leakage effect, etc. problems, to achieve the effect of promoting use, preventing welding penetration, and reducing welding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

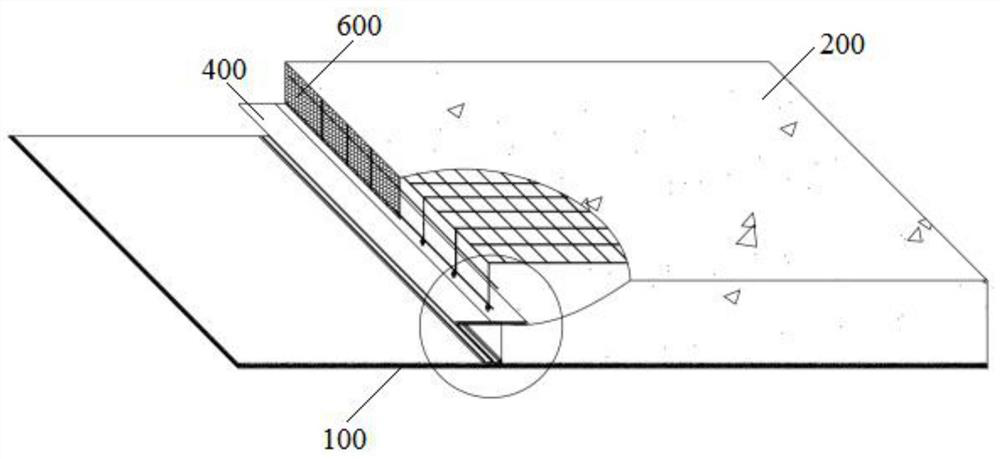

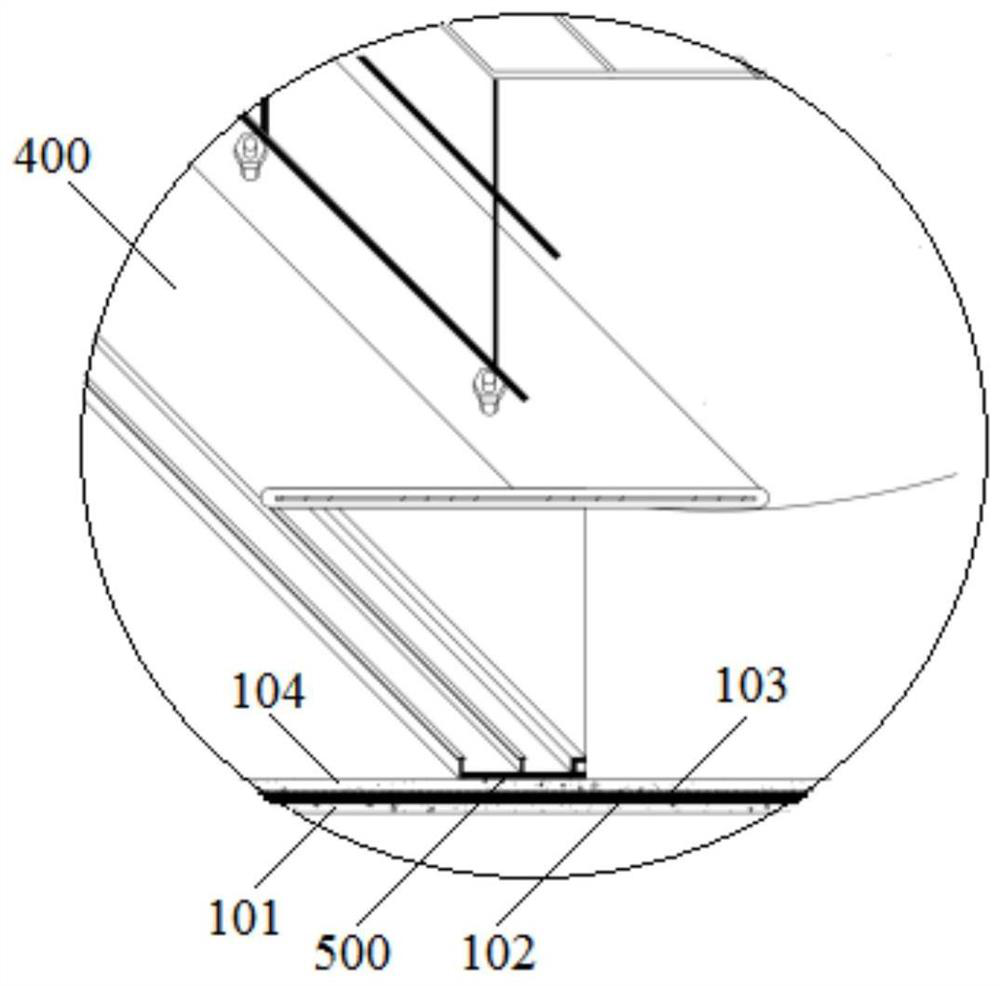

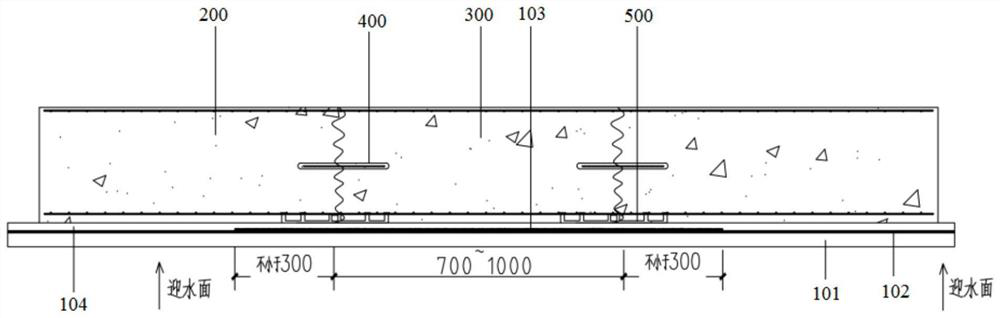

[0027] Such as Figure 1-8 As shown, a water-stop structure for post-pouring belt, including: bottom waterproof structure 100, pre-cast reinforced concrete structure 200, post-cast concrete structure 300, water-stop steel plate 400, external water-stop belt 500 and closing net 600.

[0028] Above the bottom waterproof structure 100, there are a pre-cast reinforced concrete structure 200 and a post-poured concrete structure 300. The pre-poured reinforced concrete structure 200 is located on both sides, and the post-poured concrete structure 300 is located in the middle; The bottom of the connection is provided with an externally attached waterstop 500, the middle is provided with a waterstop steel plate 400, and the end face of the connection is provided with a closing net 600.

[0029] The waterproof steel plate 400 includes a steel plate body 401 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com