Production method of non-oriented silicon steel

A technology of oriented silicon steel and production methods, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of inconsistent magnetic properties of non-oriented silicon steel and increased production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] One embodiment of the present invention provides a method for producing non-oriented silicon steel. Specifically, the production method includes the following steps.

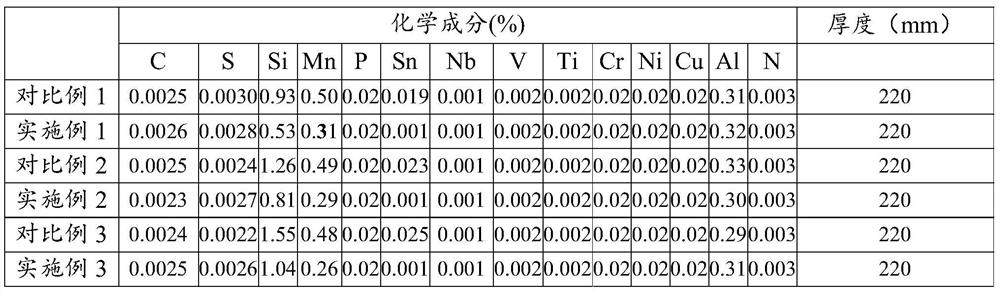

[0028] Step 1) Steelmaking is carried out according to the mass percentage of Si in the chemical composition being 0.3-1.2%, and a cast slab is prepared.

[0029] In this step 1, that is, the steelmaking process and the casting slab process, steelmaking is carried out according to the mass percentage of Si in the chemical composition being 0.3 to 1.2%. Correspondingly, the Si mass percentage in the chemical composition of the obtained slab and the final non-oriented silicon steel product is 0.3 to 1.2%.

[0030] Preferably, the cast slab obtained in step 1 has a thickness of 200-240 mm and a length of 10-11 m.

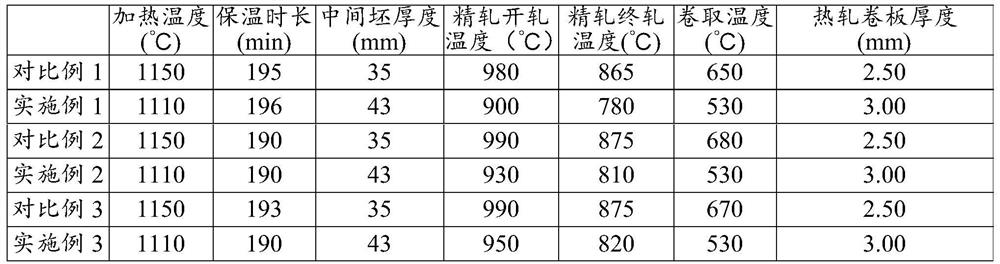

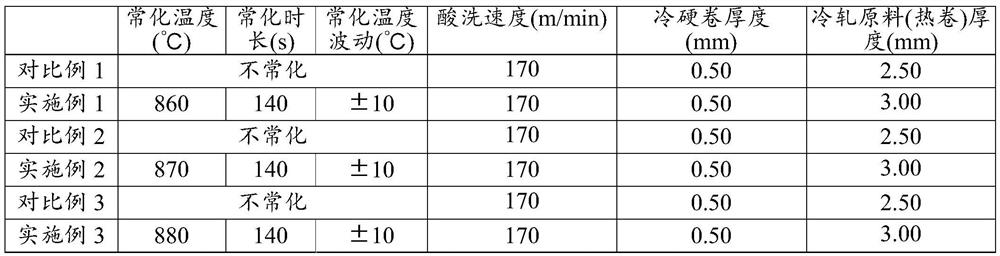

[0031]Step 2) Heating the slab obtained in step 1 to 1050-1150°C and keeping it warm for more than 150 minutes, then rolling it into an intermediate slab with a thickness of 40-45mm, and then fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com