Paper feeding mechanism and printer

A suction cup and carrier technology, applied in the directions of printing device, printing, object separation, etc., can solve the problems of high elastic modulus, easy to produce watermark, mesh, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

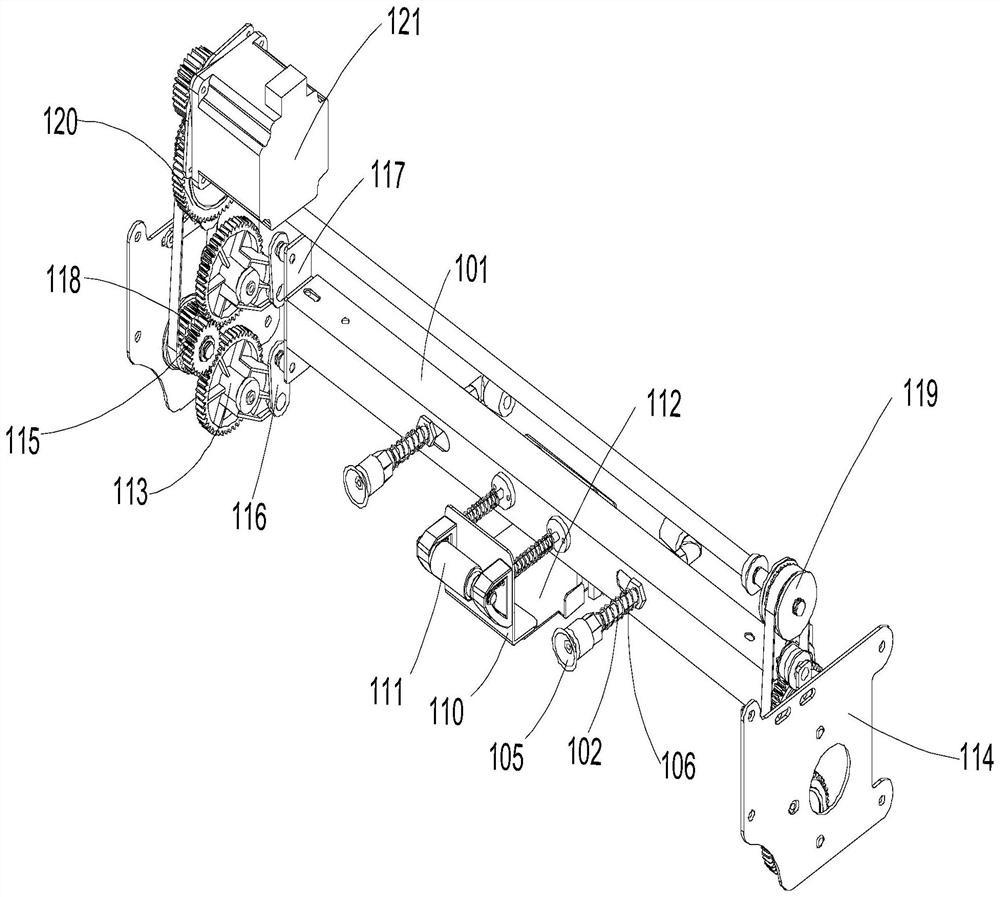

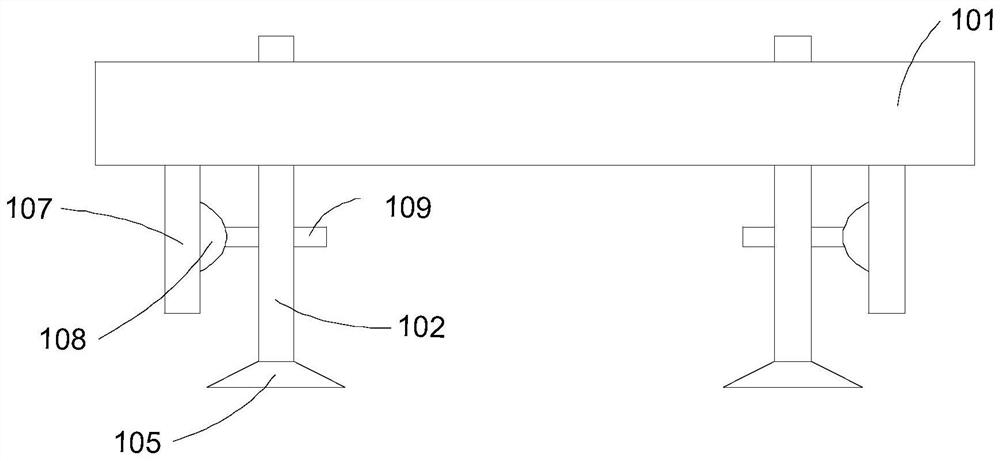

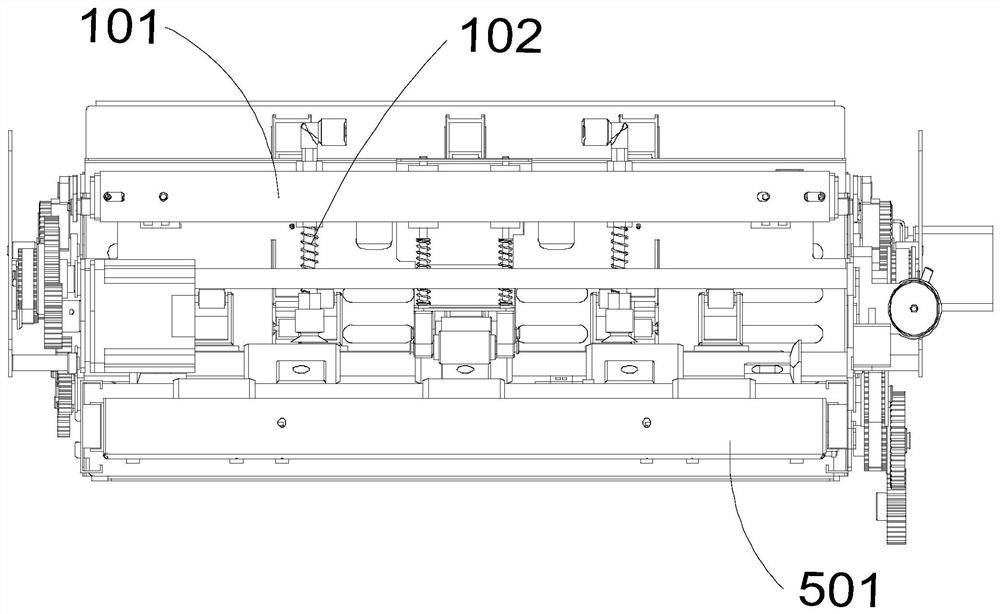

[0048] Please refer to Figure 1-Figure 16 as shown, figure 1 It is a schematic diagram of the three-dimensional structure of the paper feeding mechanism; figure 2 A simplified schematic diagram of the local structure of the paper feeding mechanism; image 3 It is a schematic diagram of the combined structure of the paper feeding mechanism and the paper feeding mechanism; Figure 4 It is a schematic diagram of the front structure of the paper feeding mechanism; Figure 5 is a stereogram of the printer; Figure 6 for Figure 5 Schematic diagram of the structure of the left view; Figure 7 for Figure 5 Schematic diagram of the right-view structure of ; Figure 8 for Figure 5 The three-dimensional schematic diagram of the internal structure; Figure 9 is a three-dimensional schematic diagram of the paper feeding mechanism; Figure 10 for Figure 9 Schematic diagram of the right-view structure of ; Figure 11 is a structural schematic diagram of the second pressed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com