A kind of road and bridge construction loading and unloading device and using method

An unloading device and technology for loading and unloading, which are applied in the field of road and bridge construction loading and unloading devices, can solve the problems of damage, inability to safely load and unload, slow speed, etc., and achieve safe load-bearing process, firm and stable connection, The effect of ensuring the safety of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

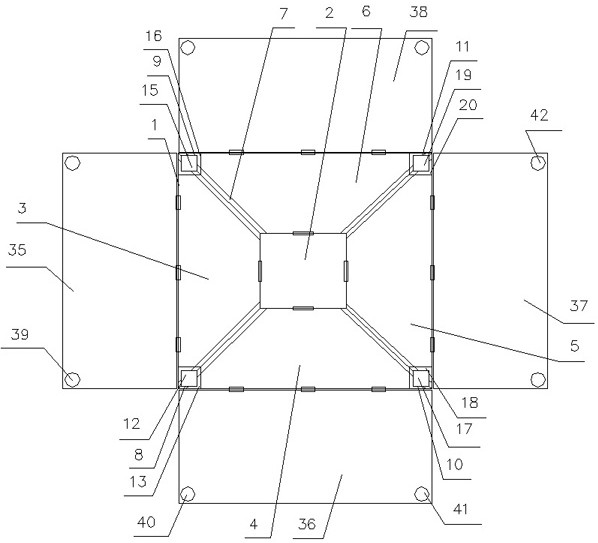

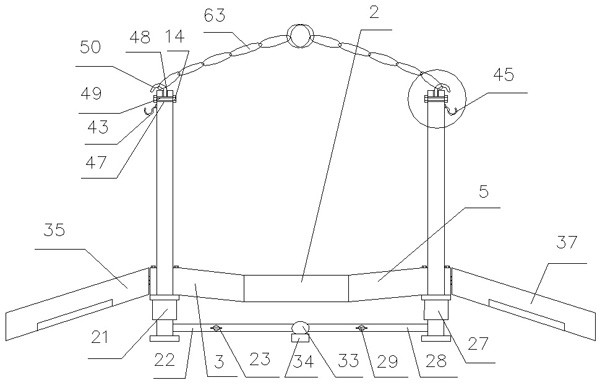

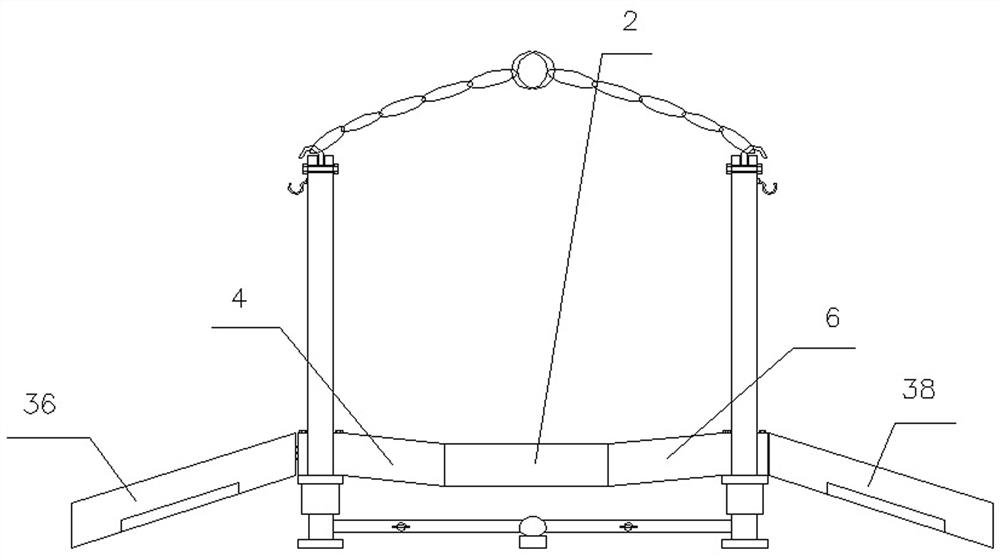

[0028] A material loading and unloading device for road and bridge construction, comprising: a bottom support plate 1, the bottom support plate includes a central square plate 2, and the central square plate is sequentially connected to the left bottom plate 3 and the front bottom plate through hinges 4. The right bottom plate 5, the rear bottom plate 6, the left bottom plate, the front bottom plate, the right bottom plate, and the rear bottom plate are all low on the inside and high on the outside, so that the road bridge installed on the bottom bracket The construction material will not slant and tilt outward, which can improve the safety of road and bridge construction materials, and also improve the safety of road and bridge construction materials during transportation. The left bottom plate, the front bottom plate, the right bottom plate, the Both sides of the rear bottom plate are oblique edges, and the oblique edges are bonded to the magnetic plate 7, between the left bo...

Embodiment 2

[0030]For a road and bridge construction loading and unloading device described in Embodiment 1, the bottom support plate is provided with a left front port 8, a left rear port 9, a right front port 10, and a right rear port 11. The port is inserted into the left front stop column 12, the bottom of the left front stop column is fixedly connected to the left front bottom plate 13, the bottom support plate and the left front bottom plate are fixed by bolts 14, and the left rear opening is inserted into the left rear stopper Column 15, the bottom of the left rear stop column is fixedly connected to the left rear bottom plate 16, the bottom support plate and the left rear bottom plate are fixed by bolts; the right front opening is inserted into the right front stop column 17, The bottom of the right front stop column is fixedly connected to the right front bottom plate 18, the bottom support plate and the right front bottom plate are fixed by bolts, the right rear opening is insert...

Embodiment 3

[0032] In a road and bridge construction loading and unloading device according to Embodiment 2, the left front opening is located between the left bottom plate and the front bottom plate, and the right front opening is located on the front bottom plate and the right bottom plate, the right rear opening is located between the right bottom plate and the rear bottom plate, and the left rear opening is located between the left bottom plate and the rear bottom plate . It can play the role of connecting the bottom plates, and can also bear the role of the blocking column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com